The Benefits of Networking Wire Processing Equipment

Networks of fully programmable wire processing equipment enable enhanced efficiency and faster changeovers, eliminate operator error, reduce lead times and WIP jobs, and improve traceability.

Pete Doyon, VP Product Management, Schleuniger Inc.

The wire processing industry has experienced significant changes and improvements over the course of the last 30 years, many of which were made possible by advances in electronics and software, and continues to evolve each day. One of the next major improvements expected to impact the market is increased efficiency resulting from networking technology.

The wire processing industry has experienced significant changes and improvements over the course of the last 30 years, many of which were made possible by advances in electronics and software, and continues to evolve each day. One of the next major improvements expected to impact the market is increased efficiency resulting from networking technology.

Most of the wire processing equipment on the market today is fully programmable, and features quick-change tooling that allows for fast changeovers between jobs. These cutting and stripping (CS) machines or cut, strip, and terminate (CST) machines are typically standalone units with their own user interfaces.

In a typical small- to medium-sized wiring harness shop, operators receive work orders on paper and either program the wire-processing machine for a job or call up that job from machine memory if it was run in the past. Determining what jobs to run, in what sequence, is usually left up to the operator, who tries to minimize changeovers in order to maximize efficiency. As such, it’s often difficult for anyone else in the company to monitor the status of a given order as it flows through the shop.

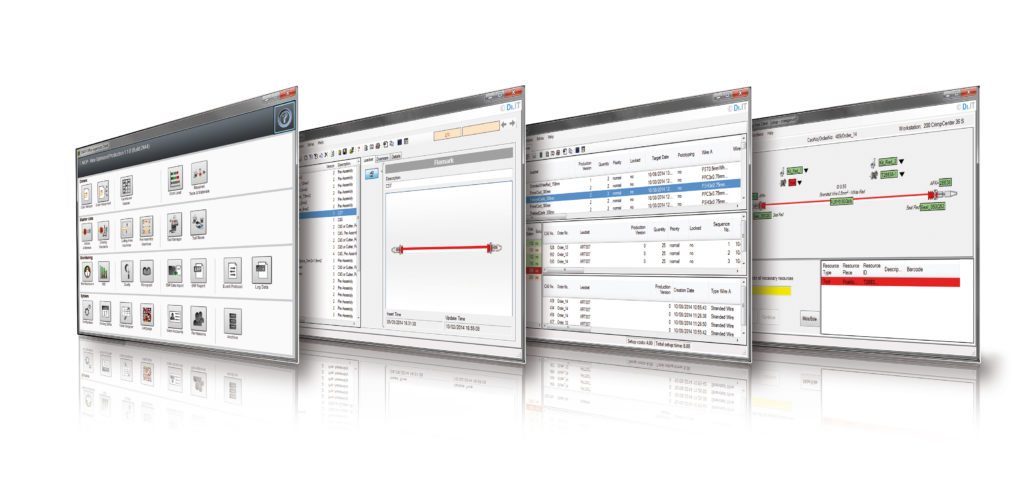

One effective solution to these problems is networking all of the wire processing equipment with a central server and dedicated software, as these elements enable a whole host of new possibilities and benefits.

Wire processing equipment networked as described provides a direct interface to existing ERP systems; eliminates operator keystrokes and the errors that could potentially result from said strokes, since jobs are automatically programmed when the work order is scanned; and maintains a central database for all crimping specs, material specs, pull force data, engineering change notices, etc. It also keeps track of how many cycles each machine, applicator, or tool has produced and when maintenance should be scheduled, and, using barcode scanners, allows all employees, rather than just the operator, to identify exactly when each job is started and completed. These scanners can also provide employees with access to the average production rate, as well as the opportunity to scan material barcodes to ensure that the proper wire, terminals, etc. are being used. Centrally networked wire processing equipment also automatically organizes work orders in the optimal sequence, taking changeover times, due dates, available machines, and personnel into consideration, and integrate mandatory quality assurance (QA) tests, including crimp height, pull test, and micrograph into the process.

Together, these capabilities significantly reduce lead times and work-in-progress (WIP) jobs, and markedly improve traceability, noting what each machine, tool, or operator produced and when. Such equipment also accurately calculates overall equipment effectiveness (OEE).

Once a company’s wire processing equipment is networked with a central server and specialized software, the possibilities and benefits become almost limitless. This type of centralized control is already common in the machine tool industry and in large wire harness operations. So, as networking technology continues to mature, it’s all but certain that it will also be adopted and cherished by small- to medium-sized wire harness operations.