Critical Requirements for Modern Medical Connectors

Critical requirements for modern medical connectors include: safety, reliability, small size, and high-speed performance.

Kirk Hilbourn, Industry Marketing Manager, JAE

Being such a small component in the grand design of any medical device, one may assume connectors to be an insignificant part of medical equipment. However, connectors play an enormous role in the proper functionality of any device. The advancement of medical technology has brought forth huge expectations for connectors. Among the most important requirements for connectors are safety, reliability, form factor, and speed.

Safety

When a patient is being treated, the last thing they need is to be exposed to is additional danger. Although uncommon, there have been reports of serious injuries, and even casualties, resulting from exposure to the conductors of a medical connector that were left accessible to human fingers. In resolution, the IEC set forth a standard requiring that connectors used in medical applications contain a form of insulation capable of preventing humans from being shocked upon contact, further enhancing the safety of utilizing modern medical devices.

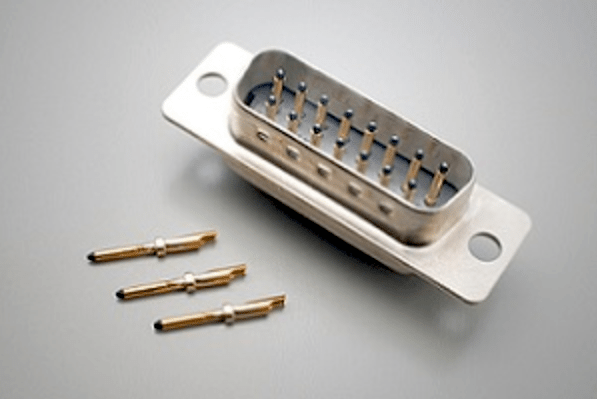

Figure 1: JAE’s ME Series D-Sub connectors feature a patent-pending design with 15 resin-insulated, touch-safe pin contacts, and are rated for 5A per pin, operating temperatures spanning -55°C to +105°C, and 500-cycle durability. Designed to deliver safe, high-reliability performance in Class I and II medical devices, including electrocardiography and ultrasonic diagnostic equipment, the series is also compliant with the third edition of IEC60601-1, clause 8.5.2.3, and is backwards compatible with legacy D-Sub connectors.

Figure 1: JAE’s ME Series D-Sub connectors feature a patent-pending design with 15 resin-insulated, touch-safe pin contacts, and are rated for 5A per pin, operating temperatures spanning -55°C to +105°C, and 500-cycle durability. Designed to deliver safe, high-reliability performance in Class I and II medical devices, including electrocardiography and ultrasonic diagnostic equipment, the series is also compliant with the third edition of IEC60601-1, clause 8.5.2.3, and is backwards compatible with legacy D-Sub connectors.

Reliability

As medical technology advances, so does the equipment used, and the professionals that we rely on likewise rely on their equipment to function flawlessly. Though connectors may seem like an insignificant component in such complex devices, they play a veritably key role in the reliability of medical equipment. When a connector is used as the junction between a probe and its medical device during a procedure, there is a high expectation for the connector to be flawlessly reliable. In this way, the reliability of a connector can directly affect the success or failure of a procedure, which, in turn, could save or cost the life of a patient. This is why the medical industry continues to invest in connectors proven to deliver reliable performance over the longevity of the equipment.

Form Factor

Similar to smartphones, medical devices have form factor requirements. As a result of recent medical advancements, surgeons can now perform certain procedures considerably less invasively. Devices now allow surgeons to complete even complex procedures that long required a patient’s body to be opened up, like heart bypass surgery, by simply creating a small incision, just large enough to insert a laparoscopic camera into and to operate equally narrow, ultra-precise tools within. The success of these types of operations is equally dependent upon the complex sets of components (e.g., connectors) within such medical devices and the surgical system’s ability to both execute and optimize the functional capabilities of devices that were once much more cumbersome to use and much more imprecise as they are dependent upon the surgeons, if not more so. In this sense, the smaller form factors that components and devices have achieved have directly contributed to drastically reducing the length and severity of the post-operative healing process, as well as the size of the scars that patients have to live with.

Figure 2: JAE’s WP27D Series 0.35mm hybrid, stacking type, board-to-board (FPC) connector meets safety, reliability, and form factor requirements for high-density mounting in slim and compact medical devices.

Figure 2: JAE’s WP27D Series 0.35mm hybrid, stacking type, board-to-board (FPC) connector meets safety, reliability, and form factor requirements for high-density mounting in slim and compact medical devices.

Speed

To help ensure that such minimally-invasive medical procedures are successful, surgeons also rely on images transferred in real-time from the laparoscopic cameras inside of patients to the monitors they use to facilitate these types of operations. Today’s connector technology allows for these large volumes of data to be transmitted at high-speeds with high integrity, which significantly contributes to the success of these sorts of operations.

One less informed of connectors’ functionality may consider them just another component in a medical device, but, for those relying on the safety, reliability, form factor, and speed of the instrument they are using, the right connector is vital.