Bigger, Better, Faster, More: Research and Development in the Electronics Industry

Bigger, Better, Faster, More: Research and Development in the Electronics Industry

Research and development (R&D) is a broad subject with many different interpretations, so any article on the discipline is subject to a critique.

Research and development (R&D) is a broad subject with many different interpretations, so any article on the discipline is subject to a critique.

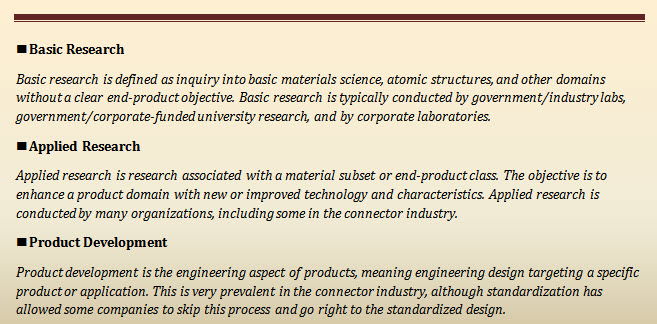

For most companies in the electronic connector industry, R&D means almost any exploratory engineering activity not directly associated with commercial product. It encompasses enabling technologies that improve, enhance, and occasionally create breakthroughs in new product development. But for the most part, connector research is tied into OEM product needs, since connectors are a component part of evolving end-product developments. For the electronics industry at large, it may be helpful to look at the big picture, represented in the chart below:

Types of Engineering Activity That Intersect with R&D

The National Science Foundation (NSF) of the United States has an R&D budget of approximately $8 billion and the European Union has dedicated 8 billion euros. While US R&D expenditures have been stagnant or in decline over the past decade, China has increased its R&D expenditures by ~20% per year over that period and is projected to surpass US expenditures in less than 10 years. The good news is that many corporations do their part and most do not depend on government funding for their R&D priorities. In our industry, look to Intel, IBM, HP, and others — including innovative startups — to bridge the gap between public, private, and university research. An issue here is that private developments are owned by individual companies and may not be available to the industry at large. But they do show the way forward, and tend to steer the market toward related breakthrough technologies.

Some Materials and Systems R&D Priorities

Many important technologies need significant R&D for companies in our industry to survive and flourish into the mid-21st century. We look at a few, starting at the materials science and systems level, then moving into connectors. (Some observations here are based on recent iNEMI.org findings.)

Semiconductor Research

Semiconductor Research

Research focused on “beyond 10nm” and ways to circumvent the approaching atomic levels of semiconductor technology is far and away the most important R&D development for the electronics industry. That research is well under way, including packaging developments to stack die into multi-chip systems-in-package. This research will have a profound and hopefully positive impact on the connector industry, meaning the semiconductor engine of growth in the electronics industry will continue beyond Moore’s Law. But it could also evolve into highly integrated systems requiring fewer internal connectors.

Unknown Possibilities

There are other breakthroughs lurking out there. We just don’t know what they are yet. They may get here quicker than we thought but the incubation period is usually a half-decade or more. Quantum mechanics, associated with semiconductor research, may be one; on-chip photonics another.

Nano-Materials Technology

New encapsulating materials and possible super-conductivity of connector contacts hold significant promise for the industry at large, and for the connector industry in particular. This area is paralleled by developments in metallic alloys, with conductivity improvements slated to go from 20-30% to 70-80% of pure copper.

Breakthroughs in Transportation

As the connector industry’s biggest market, developments here are not to be taken lightly. Hats off to Toyota, who revolutionized auto travel with the introduction of hybrid vehicle technology — and much of that was not basic research but rather applied research and disparate technology integration into hybrid vehicle drive trains. The next development may be a make-or-break situation for society: An economical mode of carbon-free transportation within the existing infrastructure of roads and highways. In public transit, is Elon Musk’s Hyperloop 700 mph railgun train next?

Smart Grid

If implemented — and that is a big if, considering current fiscal challenges — the smart grid could be a large market for connectors, both electronic and electrical.

Alternative Energy Developments

This is well underway, but expansion will be hampered by pullback in government support. Solar does hold great promise in its next generation, which will include flexible solar panels for automotive and other uses.

Computer/Datacom Technologies

Have we reached the end of the line in PC developments versus smartphones and tablets? What breakthroughs might rejuvenate the high-volume PC industry? Tied into this are new developments and applications for microprocessors, including very low power mobile chip sets for servers and PCs. Display technology is also important, as is memory (MRAM?) and the memory technologies beyond DDR4 and NandFlash. To my way of thinking, nothing will replace the PC/Mac except a change in the way people approach computing, and that is happening now: Eventually, all intelligence will be accessible in the cloud.

Artificial Intelligence and Analytics

Spearheaded by IBM and others, this places the expertise for running a business, predicting the best courses of action, and perhaps even R&D outcomes in the hands of programmers and big black boxes.

Microsystems Technology

This describes a range of activities in Si/MEMS/sensors and IC packaging, highly integrated substrates and interconnect technologies associated with very small, even microscale electronics. The urgencies in this area of development result from powerful forces: The end of Moore’s Law scaling on a single chip, growth in systems-in-package, wearable/implantable electronics, and the Internet of Things goal of making everything “connected and smart.”

Lightwave Systems

These systems will fully utilize the speed and bandwidth of electro-optics to develop all-optical systems. Ironically, we may have known more about this 10 years ago than now. During the downturn in 2001 and the early crash in landline telecommunications, much promising research was stopped due to a lack of funding and then put on the back burner as copper systems, aided by signal conditioning chips, marched toward multi-Gb/s. Key factors here may include optical Si; direct off-chip interconnect, connector, and substrate technologies, including polymer waveguides; and, most important, applied cost technology.

In order to reach the breakthroughs in the areas mentioned above, research in the connector industry requires a number of capabilities in order to move the technology to the next level.

Connector Research Needs*

- High Speed Signal Metrology

While connectors are not the biggest issue here, improvement is needed as we cross the 10Gb/s threshold. Connector designs need to be invisible at 10, 25, and possibly 40Gb/s or economical fiber optic connector/cable solutions need to be developed. This research needs to move forward in conjunction with the materials science, semiconductor, cable, substrate, and electronic packaging regimes necessary to make fiber optics a viable high-volume manufacturing (HVM) solution. - Standards in Reliability Qualification

As an electromechanical component with a myriad of application parameters, is it possible to develop predictive reliability/MTBF data based on an analytics or testing approach to different connector designs and applications? This is a question posed by the OEM and EMS community that purchase connectors for use in electronic systems. - Dynamic Warpage Measurement

This question relates to large, thin engineered plastic connector designs such as DDR4 and CPU sockets approaching 2,500 contacts (and also large BGA packages) that are exposed to the higher surface temperatures associated with lead-free solder processes and the thin-web injection-molded designs of these products. - Key Challenges with Press-Fit Connectors

There are mechanical, high-speed signaling, power, and packaging issues here. In the automotive industry, for instance, press-fit connectors are desired for a range of applications and need to be characterized for harsh environments. In backplane and midplane applications approaching 25 to 40Gb/s, board-to-board connectors, high-speed twin-ax cables, and fiber optics will all remain in use. - State-of-Art Memory Connector

JEDEC DDR4 specs are finalized, but as DDR4 approaches or exceeds its maximum 3.2Gt/s — or the next-generation memory technology surfaces — what challenges need to be overcome to ensure a cost-effective socketed or otherwise upgradeable memory connector? - Emerging Needs in Future Automotive Connectors

Press-fit was mentioned above. There are also special connector needs in drive train and electromotive system interconnects for modules, HEV, PHEV, emerging battery, fuel cell, solar, and other applications. - Advanced Materials Research

This will include metallic alloys and sealing/encapsulating materials as well as applications such as injection molding, printing of new complex designs, and flexible circuitry. - Advances in Fiber Optics

Significant challenges in fiber optics include chip/package interconnects, cost-effectiveness, connector termination improvements, packaging architecture, waveguides, and interconnects, including optical PCBs. - Micro-Interconnect Technology

This includes materials and process for sub-100um interconnects, when and if they are needed. - Future Connector Designs in an All-Si World

This question requires more intense dialogue between connector manufacturers and the semiconductor and packaging industries. This is a challenge because the semiconductor and packaging segments are not major connector users except for test; their R&D organizations are even less accessible; and there are proprietary obstacles.

What are your ideas for future connector R&D requirements? What are the big ideas beyond niche research? Let me know at [email protected].

*Some information courtesy of iNEMI’s exploratory initiative on connectors

- Electric Vehicles Move into the Mainstream with New EV Battery Technologies - September 7, 2021

- The Dynamic Server Market Reflects Ongoing Innovation in Computing - June 1, 2021

- The Electronics Industry Starts to Ease Out of China - November 3, 2020