Automotive

Connector & Cable Special Topics

Consumer

Datacom/Telecom

Industrial

Materials

Medical

Military/Aerospace

Sensors/Antennas

Transportation Connectors

Wire & Cable Assemblies

New technology

Optics Outpace Copper at OFC 2024

Bob Hult shares the phenomenal advances in high-speed optical communications showcased at OFC 2024, including interconnects for 200G per lane optical transmission, liquid cooling, co-packaged optics, PAM6, and other technologies that take us far beyond the reach of copper. The 2024 Optical Networking and Communication Conference and Exposition March 24-April 3 in San Diego nearly filled the convention center and attracted over 13,000 participants…

Get the Latest News

Technical Expertise

How to Select Electrical Connectors for LEO Satellites

The challenges of space are extreme: Outgassing, UV radiation, vacuum and oxygen conditions, and the unique harsh environment factors of low Earth orbit require careful consideration in component selection. Humanity launched the first rocket into space…

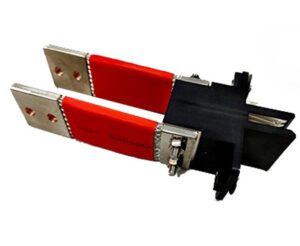

Building a Better EV Battery Monitoring System

New interconnect technologies help design more efficient, more powerful electric vehicles beginning with the battery pack. The foundation of any electric powertrain is the EV battery pack, as it is here that electrical energy supplied by…

The Universal Genius of M12 Connector Technology

When it comes to sensor and actuator applications, the M12 circular connector with A-coding is the first choice. Regardless of whether it is a matter of transmitting signals, data, or electrical power, M12 connectors have become…

Beyond the Basics: Customer Specific Connectors

Every element of a connector contributes to the success of a design. When selecting an application-specific connector or designing a custom solution, consider how each part contributes to system performance and longevity. The quality of the…

Product Roundup

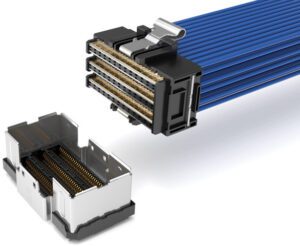

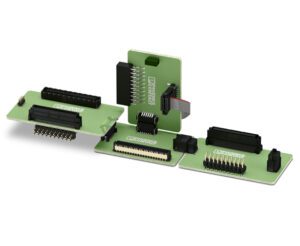

Mezzanine Connectors Product Roundup

This week’s Product Roundup highlights mezzanine connectors from leading connector manufacturers and suppliers. Mezzanine Connectors The Archer .8 series from Harwin has a 5 mm stack height. These cost-effective, dual-row 0.8 mm-pitch board-to-board connectors are intended…

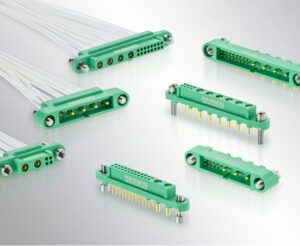

MIL-Spec Rectangular Connectors Product Roundup

This week’s Product Roundup highlights rectangular MIL-spec connectors from leading connector manufacturers and suppliers. Rectangular MIL-Spec connectors Amphenol’s HDB3 rectangular connectors from Avnet incorporate a higher density contact pattern and lower mated height than Amphenol’s…

Automotive Connectors Product Roundup

This week’s Product Roundup highlights automotive connectors from leading connector manufacturers and suppliers. Automotive connectors Vishay high-current density TMBS eSMP rectifiers from Avnet are ideal for automated placement and feature Trench MOS Barrier Schottky technology (TMBS).…

High-Speed Cable Solutions Product Roundup

This week’s Product Roundup highlights high-speed cable solutions from leading connector manufacturers and suppliers. High-Speed Cable Solutions 3M Twin Axial PCIe Extender Assemblies for PCIe 4.0 applications, available from Avnet, is a family of cable assemblies…

Food-Safe Interconnects Product Roundup

This week’s Product Roundup highlights food-safe interconnects from leading connector manufacturers and suppliers. Food-Safe Interconnects CDM Electronics supplies binder cable assemblies in a variety of preconfigured cable lengths and connector orientations. Cordsets feature standard M12 connectors…

Meet the Connector

Meet the Connector

Meet the Connector: DIN Standard Connectors

The German standards organization DIN is behind the quality, safety, and interoperability of electronic components used around the world. The term "DIN connector" refers to a wide range of connectors that adhere to standards set by the Deutsches Institut für Normung (DIN) or German Institute for Standardization. DIN…

How to Specify