The Robots in Your Future

Today we see all types of robotic devices that do everything from vacuum your floors to clean up nuclear waste. Originally focused on industrial and hazardous applications, robots are now appearing in warehouses, hospitals, and even the home.

The concept of automated devices that extend human capabilities has sparked the imagination of people for many years. In 1956, Robby the Robot fascinated moviegoers while pulp science fiction magazines featured robots as early as 1935.

The concept of automated devices that extend human capabilities has sparked the imagination of people for many years. In 1956, Robby the Robot fascinated moviegoers while pulp science fiction magazines featured robots as early as 1935.

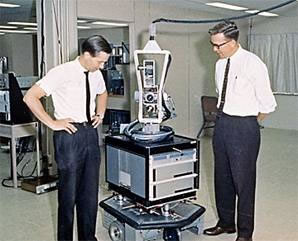

One of the first electromechanical humanoids was a DARPA project aimed at collecting military reconnaissance data. Shakey was mobile, autonomous, verbally interactive and, using rudimentary vision, was capable of mapping its surroundings. This was pretty amazing given the state of computing at the time.

Shakey, the first humanoid. Photo courtesy of SRI International

Today we see all types of robotic devices that do everything from vacuum your floors to clean up nuclear waste. Originally focused on industrial and hazardous applications, robots are now appearing in warehouses, hospitals, and even the home.

Industrial and commercial robotic arms have been assigned to repetitive, dirty, and dangerous tasks that range from automated paint-spray booths to bomb disposal. Large robots have been used in steel mills where the ability to manipulate heavy loads and exposure to heat and fumes makes a human operator problematic. The relative high cost of robots had limited their use to applications with few alternatives. Early robots were designed for highly specialized jobs with little ability to take on new tasks.

Those paradigms are changing as new robotic devices are able to quickly “learn” new jobs, cost less, and adapt to working around people.

In the past, industrial robots were isolated from humans as their rapid movements and inability to recognize and avoid nearby people posed a serious safety threat. Newer machines have been designed to directly assist humans. This new breed of collaborative machine is being adopted by many smaller companies that can take advantage of the increased productivity offered by robotics.

Robotic machines can be fixed or mobile, depending on the anticipated application. Mobile autonomous robots now deliver hospital meals, medications, and linens to patients. These robots are designed to work among people and are outfitted with an array of sensors including vision systems that prevent collisions. Some of these robots are guided by location beacons while others use GPS for navigation.

Amazon utilizes a fleet of robots in its network of fulfillment centers to fetch and deliver product to human shippers. Utilizing these robotic pods allows Amazon to constantly reduce delivery time and cost.

Robotic hands have been refined to the point that they can grasp fragile items without damage. Covered with a soft skin-like rubber embedded with pressure sensors, these hands take on a remarkably human-like feel.

Major progress is being made in all classes of robotic devices including those with humanoid form factors. The Honda ASIMO robot was one of the first to be able to walk, while newer robots feature voice recognition/generation, reactive facial expressions, and even the ability to right themselves if tipped over. Otto, a desktop-sized robot from Samsung, is designed to be user-friendly as it manages the elements of a smart home, and Pepper, from Soft Bank Robotics, is the first humanoid robot designed specifically to live with people. It opens a new category of robotic companions that are not designed to do work, but rather provide social contact.

Contractors for DARPA are developing robots for use in disaster relief. Robots must be able to open doors, climb stairs, and maneuver around building debris. Four-legged robotic “mules” can carry loads over log-strewn forests.

Robotic devices are highly complex electromechanical machines that may contain multiple computers, dozens of sensors, power management systems, multiple motors, hydraulic pumps, actuators, and wireless connectivity to the Internet. Reliability is a critical issue, especially as many robots must survive on a factory floor or even outdoors. They consist of many subassemblies, which offer prime opportunities for small, reliable, and rugged connectors.

As robotic devices evolve from relatively few highly specialized devices to broad market applications including consumer, leading connector manufacturers have recognized the growth potential. Suppliers such as Amphenol Industrial, Harwin, LEMO, Molex, ODU USA, Omnetics, and TE Connectivity have created product microsites to promote connector product families applicable to robotic applications.

As robotic devices evolve from relatively few highly specialized devices to broad market applications including consumer, leading connector manufacturers have recognized the growth potential. Suppliers such as Amphenol Industrial, Harwin, LEMO, Molex, ODU USA, Omnetics, and TE Connectivity have created product microsites to promote connector product families applicable to robotic applications.

In addition to standard interfaces such as circular military, commercial plastic, and USB connectors, suppliers such as Molex have introduced new connectors specifically designed for use in robotic applications. The Compact Robotic Connector (CRC) family from Molex is an example of a new connector that incorporates key features required in robotic equipment including power/signal contacts, positive latching, and a shielded housing.

The ROB connector from ODU USA features IP67 environmental sealing and resistance to extreme vibration.

The ROB connector from ODU USA features IP67 environmental sealing and resistance to extreme vibration.

Omnetics developed its OmneMed plastic circular connector for robotic medical applications where high reliability and mating cycle life are absolute requirements.

Omnetics developed its OmneMed plastic circular connector for robotic medical applications where high reliability and mating cycle life are absolute requirements.

The ARISO contactless interconnect from TE Connectivity is an ideal signal and power interface for a robotic arm where 360-degree rotation is required in a harsh environment.

The ARISO contactless interconnect from TE Connectivity is an ideal signal and power interface for a robotic arm where 360-degree rotation is required in a harsh environment.

Research is now underway to integrate artificial intelligence into next-generation robotic devices. Rather than simply follow programmed commands, robots in the near future will observe and analyze a situation to identify the best response. The Echo from Amazon is an example of what can be achieved when a device using advanced algorithms and natural speech recognition has the ability to access all of the knowledge available on the Internet. Rather than simply gathering and reporting information, internet-connected robots with artificial intelligence will be able to take action to complete complex tasks.

Continued growth of robotic machines of all types will generate expanding opportunities for associated connectors and sensors.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024