Data-Intensive Battlefields Drive the Need for Fiber Optic Solutions and Training

By Jenny Bieksha, Bishop & Associates Inc., and Donald Stone, Fiber Optic Design Engineer, KITCO

June 19, 2012

The military is just beginning to experience the same explosion of data that has been seen in the enterprise world. The challenge is to provide systems with enough performance to  process and store this data. Technology and applications need to address how to sort through all the sensor data being collected faster, easier, and using less manpower, as the appetite for more data will only increase.

process and store this data. Technology and applications need to address how to sort through all the sensor data being collected faster, easier, and using less manpower, as the appetite for more data will only increase.

Military conflicts are becoming increasingly digitalized. Battlefields are transforming into robust networks of informed, geographically separated military personnel. Growth in the number and the capabilities of sensors and robotic platforms has accelerated the generation of data. Sensor-laden unmanned vehicles are being fielded in greater numbers, generating a wealth of data and driving the need for faster, more secure networks, greater bandwidth, increased processing power, and data storage.

Interconnect devices are critical to today’s network-centric and data-intensive battlefield. Fiber-optic solutions in mil/aero electronic systems are proliferating, due to high-bandwidth requirements and better immunity to interference and jamming. Fiber optic links between antennas and communication centers provide high-bandwidth secure links capable of supporting many channels of high-definition video. Fiber also provides an exceptional medium for remote sensors that can detect enemy movement, as well as perform in electronic countermeasure equipment.

Interconnect devices are critical to today’s network-centric and data-intensive battlefield. Fiber-optic solutions in mil/aero electronic systems are proliferating, due to high-bandwidth requirements and better immunity to interference and jamming. Fiber optic links between antennas and communication centers provide high-bandwidth secure links capable of supporting many channels of high-definition video. Fiber also provides an exceptional medium for remote sensors that can detect enemy movement, as well as perform in electronic countermeasure equipment.

In research on fiber optics in the defense market, we encountered a seldom-referenced but essential part of the electronics supply chain: training. As electronic systems grow increasingly complex, OEMs require the training to maintain these systems. KITCO Fiber Optics has developed a solid reputation for providing fiber optic connector products and consulting services to the military and commercial communications industry, and is actively engaged with training and field services for several UAV platforms.

In the following section, Donald Stone, KITCO fiber optic design engineer, provides insight into the growing need for fiber optics training in the military industry. To learn more about KITCO Fiber Optics, read our interview with Mr. Geoff Clark, president and CEO, following this article.

Fiber Optic Systems Training Minimizes UAV Downtime

Fiber Optic Systems Training Minimizes UAV Downtime

Unmanned vehicles are primarily used for reconnaissance, gathering information about terrain and enemy movements. Whatever the type of unmanned vehicle — whether land, sea, or airborne – its mission will typically comprise three key elements: data capture, data processing, and data transmission. There is also a need for onboard flight management and control systems, and in some instances, weapons management systems. Solutions need to deliver high performance and rugged reliability with minimal impact on space, weight, and power.

Unmanned Aerial Vehicles (UAV) represent one of the largest growth markets for fiber optic products. These devices demand reliable real-time video transmission in potentially EMI-intense environments while surviving continuous shock and vibration. Applications require reduced weight and bulk, as well as high bandwidth and resistance to EMI, all attributes of fiber. Due to the unique handling, inspection, cleaning, and testing techniques related to fiber, there is a growing demand for specialized training of technicians to maintain the fiber optic systems for both the UAV and shelters in the field.

Unmanned Aerial Vehicles (UAV) represent one of the largest growth markets for fiber optic products. These devices demand reliable real-time video transmission in potentially EMI-intense environments while surviving continuous shock and vibration. Applications require reduced weight and bulk, as well as high bandwidth and resistance to EMI, all attributes of fiber. Due to the unique handling, inspection, cleaning, and testing techniques related to fiber, there is a growing demand for specialized training of technicians to maintain the fiber optic systems for both the UAV and shelters in the field.

Standards exist to address aerospace fiber optics for both the commercial air transport industry and the military. A majority of the UAVs are military in nature. There is also work being done with the Society of Automotive Engineering (SAE) under the Aerospace Systems Group (ASG). Aerospace standards cover the various aspects associated with fiber optics. A critical factor contributing to successful deployment of a UAV concerns the inspection and cleaning of fiber optic connectors.

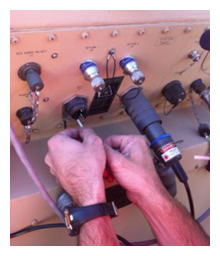

One of the primary support systems for UAVs is the shelter, where the pilot sits to fly the UAV. These shelters are mobile, and get setup and broken down numerous times during their deployment. The shelter uses fiber optics to communicate with the UAV and is shut down when the fiber optic systems are not functional. It is therefore very surprising that fiber optic support kits are rarely provided with the shelter or the UAV. As a result, technician training is typically overlooked. Most of the maintenance and troubleshooting being performed today entails removal and replacement of the fiber optic cable reel that attaches to the shelter. This is done because the technician does not have any type of inspection or cleaning kit to assist in the troubleshooting process. This leads to unnecessary downtime of the UAV and shelter, and the added cost of installing a new harness.

One of the primary support systems for UAVs is the shelter, where the pilot sits to fly the UAV. These shelters are mobile, and get setup and broken down numerous times during their deployment. The shelter uses fiber optics to communicate with the UAV and is shut down when the fiber optic systems are not functional. It is therefore very surprising that fiber optic support kits are rarely provided with the shelter or the UAV. As a result, technician training is typically overlooked. Most of the maintenance and troubleshooting being performed today entails removal and replacement of the fiber optic cable reel that attaches to the shelter. This is done because the technician does not have any type of inspection or cleaning kit to assist in the troubleshooting process. This leads to unnecessary downtime of the UAV and shelter, and the added cost of installing a new harness.

Shelters are typically located in desert environments where the dust and dirt is the consistency of powder and gets into even the best sealed components. KITCO offers an inspection and cleaning kit containing the necessary tools to clean the fiber optic connector termini end faces and bring the fiber optic system back online. This can be done without removing and replacing the entire harness. An “all-in-one” combination kit is also available that includes tools for fiber optic testing, inspection, and cleaning. It includes a small handheld optical time domain reflectometer (OTDR) with built-in inspection capabilities. This combination kit is needed to test the concatenated fiber optic links that run from the shelter out to the directional antenna that communicates with the UAV. The length of these runs can be quite long, and the OTDR will help narrow down where the fault is located. The fault area can then be inspected and cleaned.

Shelters are typically located in desert environments where the dust and dirt is the consistency of powder and gets into even the best sealed components. KITCO offers an inspection and cleaning kit containing the necessary tools to clean the fiber optic connector termini end faces and bring the fiber optic system back online. This can be done without removing and replacing the entire harness. An “all-in-one” combination kit is also available that includes tools for fiber optic testing, inspection, and cleaning. It includes a small handheld optical time domain reflectometer (OTDR) with built-in inspection capabilities. This combination kit is needed to test the concatenated fiber optic links that run from the shelter out to the directional antenna that communicates with the UAV. The length of these runs can be quite long, and the OTDR will help narrow down where the fault is located. The fault area can then be inspected and cleaned.

It goes without saying that fiber optics is still new territory for the UAV technician. Certain skill sets are required to properly install, inspect, clean, test, and troubleshoot the fiber optic cable harnesses. Properly trained technicians, with the appropriate tool kits, will help to maximize shelter efficiency and keep the UAVs airborne.

Bishop Notes:

The House Appropriations Committee’s defense subcommittee recently passed its version of the 2013 National Defense Authorization Act, a $608 billion bill, which is more than $3 billion over the DoD plan proposed by President Obama. It revives some programs the Pentagon planned to cut next year, including $278 million to keep the RQ-4 Global Hawk Block 30 UAVs. The DoD proposed budget would have cut procurement and research spending on communications and electronics by almost 25% in the next two years. The bill is now in the hands of the House Armed Services Committee.

SPOTLIGHT on Mr. Geoff Clark, President and CEO, KITCO Fiber Optics

ConnectorSupplier.com: Tell us more about KITCO and its role in the electronics supply chain.

KITCO: We are a leading provider of ruggedized fiber optic connector products, training, and services to the military and commercial communications industry. Our business base has grown to be 80% Department of Defense focused with emphasis on the Navy (shipboard and aviation), Marines (ground tactical), Army (ground tactical and aviation), and Air Force (aviation). Within the arena of communications, command and control, and combat systems support, we have found the real need for a total fiber optic solution (products and services) to meet the growing need of this technology in the marketplace.

CS.com: What trends do you see in your marketplace?

KITCO: The growth of fiber on various defense platforms (ships, tanks, aircraft, UAVs, etc.) is undeniable. As a result, interest in better understanding the unique characteristics of ruggedized fiber is growing as well. Still, we see the life cycle maintenance and repair as an afterthought at times.

CS.com: What are the major issues you must contend with?

KITCO: There is not yet a complete commitment to in-depth training in the ruggedized fiber optic market. Many of the issues involving fiber problems have straightforward solutions, assuming that the proper hands-on training and investment in tools and equipment is made. If that’s done, the return on these investments is outstanding. Classic example: adopting a rigorous clean and inspect protocol with the proper equipment.

CS.com: What types of fiber optic products do you most frequently deal with?

KITCO: M28876, M38999, ARINC 600, ARINC 801, M64266, and M83522/16 are most common. However, we also work with customer-specific fiber optic products.

CS.com: What major forces do you see driving the mil/aero industry today?

KITCO: Faster, more reliable data in the field is also a huge advantage in a combat environment. Having intelligence in advance or during a conflict saves the lives of our combatants and allies, and helps to neutralize our enemies. As many know, the inherent advantages of fiber are weight (compared to copper), broadband (again, compared to copper), and security (EMI versus copper).

CS.com: How is KITCO responding to these factors?

KITCO: We have developed training, kits, and tools, and we have repair capabilities designed specifically to address the ruggedized requirements in the shipboard, ground tactical, and aviation environments. Beyond these capabilities, we are often called upon as DoD subject matter experts in ruggedized fiber optics to troubleshoot and consult on design issues.

CS.com: What separates KITCO from other suppliers in the industry?

KITCO: What makes KITCO unique in the industry is our “closed loop value proposition.” That is, although we have competitors in every segment of our business (kits, cable assemblies, training, and field services), no one competitor offers all of our capabilities in an unbiased way. We are not an equipment or connector OEM, therefore, we have the freedom to recommend the solutions our customers need and deserve, regardless of the manufacturer. We work closely with our OEM partners to ensure they have the right solution for the end user. Our “closed loop” suggests that everything we do is within the capability of our employees’ expertise and capability worldwide.

CS.com: What are KITCO’s future growth plans?

KITCO: Our most recent success story is our growth in the military and commercial aviation arena. We have been working tirelessly at establishing a foothold in this growing fiber market. By our direct involvement in SAE, ARINC, and various industry trade exhibits, we are now recognized as the “go to” people for training and kitting. With the constant growth of data rates, defense spending focused on the biggest bang for the buck, C4ISR, and so on, we see our company continuing to grow as the market grows in the fiber arena. We are confident that fiber optics will be growing at a far greater rate than that of the legacy technologies out there today. Fewer new construction opportunities will mean more alteration and upgrade work on existing platforms. These alterations and upgrades will undoubtedly require fiber optics as a growing part of the solution.

Visit KITCO online.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024