Robust Connections: Board-to-Board Connectors for the Industrial Market

As automation and the Internet of Things transform industrial environments, demand is increasing for electronics with interfaces for signal, data, and power transmission, as well as shielding from harsh environmental conditions. Board-to-board connectors are an important component in the fourth industrial revolution or Industry 4.0.

By Markus Sonderer, Senior Director of Product Marketing and Development, Phoenix Contact GmbH & Co. KG, and James Dunbar, Product Marketing Manager, Phoenix Contact USA board-to-board connectors

“Smart factory,” “intelligent factory,” and “IIoT” are just a few of the buzzwords that have been driving Industry 4.0 innovation in the industrial production and automation sector for the past five years. In diverse global regions, including the US, Europe, and China, manufacturers are actively implementing changes to make industrial production more networked, more efficient, more intelligent, and more internationally competitive. Robust board-to-board connectors are an important component in this effort.

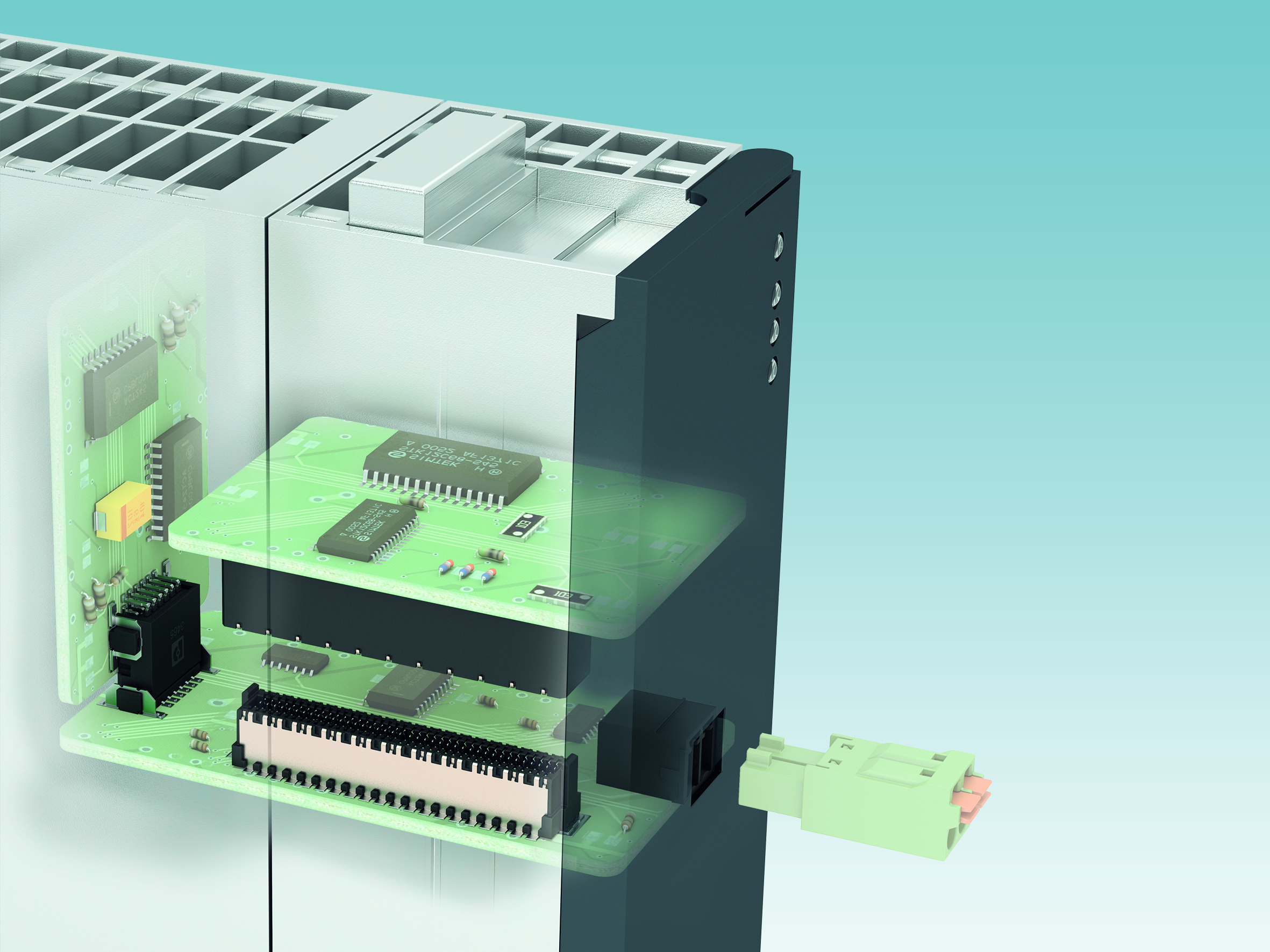

Intelligent solutions for the intelligent factory: Board-to-board connectors allow connections in new dimensions.

One of the key drivers of increased international competition is enhanced production resources designed to lead to higher performance, more flexible production lines, and lower manufacturing costs. By the year 2020, various analysts predict the world will have 20 billion (IDC, 2016), almost 30 billion (Gartner, 2017), or even up to 50 billion (CISCO IBSG, 2011) IT-networked devices. In these scenarios, there will easily be more things communicating with each other than people.

While we are all familiar with the way smart devices like phones and tablets have become a part of our lives, we are also seeing more intelligent devices networked in the industrial world, including controllers, power supplies, input/output devices, and human-machine interfaces (HMIs). Processors and other electronic components used in these devices have become less costly to produce, which has significantly increased both the number and the power of these devices while simultaneously decreasing their overall size. This has resulted in less centralization as more intelligent devices are moving into the field.

Demanding Industrial Requirements

With more field devices comes the need for better networking. These devices require appropriate electronics and interfaces for signal, data, and power transmission, as well as shielding from harsh environmental conditions. Electromechanical interfaces play an important role here, as they are the key to exploiting further miniaturization potential and making industrial devices more reliable and more flexible. However, dirt, vibration, high temperatures, and electromagnetic radiation place high demands on electronic components.

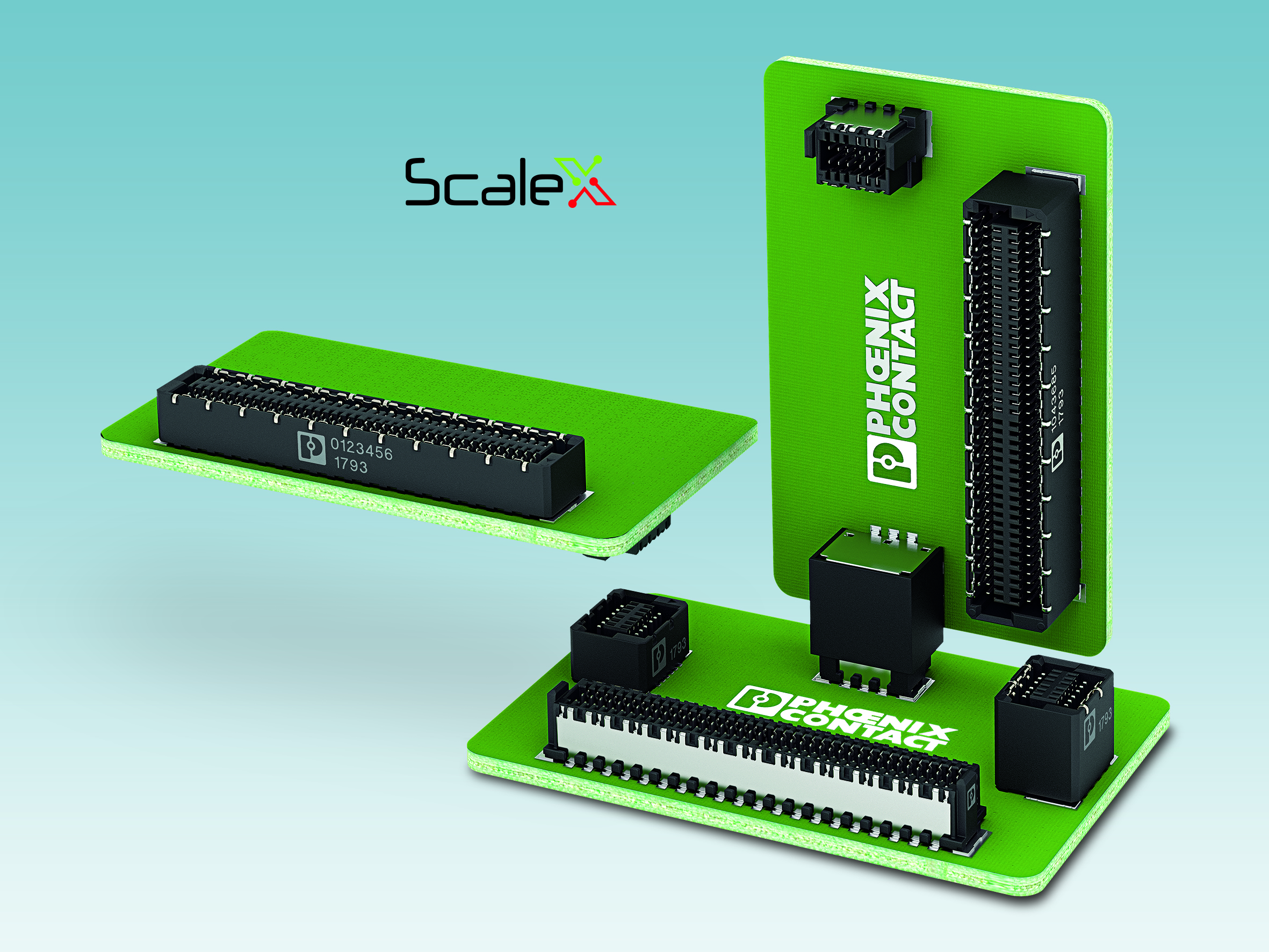

Many newer board-to-board connectors can meet these demanding requirements. For instance, versions with 0.8mm and 1.27mm pitches are often ideally suited for the device and internal connections of several printed circuit boards (PCBs), while vertical variants make it possible for device manufacturers to implement mezzanine, orthogonal, or coplanar PCB arrangements, which supports more flexible electronic layouts for broader application suitability.

Miniaturized and reliable: Board-to-board connectors are used for the internal connection of printed circuit boards

Flexibility on the PCB

Some of the newer board-to-board connectors can handle currents up to 1.4A and voltages up to 500VAC and accommodate applications with 12 to 80 connection points. Reverse polarity protection is particularly important in board-to-board connectors with compact centerlines, as it prevents damage to the contact interface during the mating process and helps ensure stable, long-term connections inside the device. As such, the insulating housings of many board-to-board connectors have a special geometry that prevents the mismating of male and female connectors.

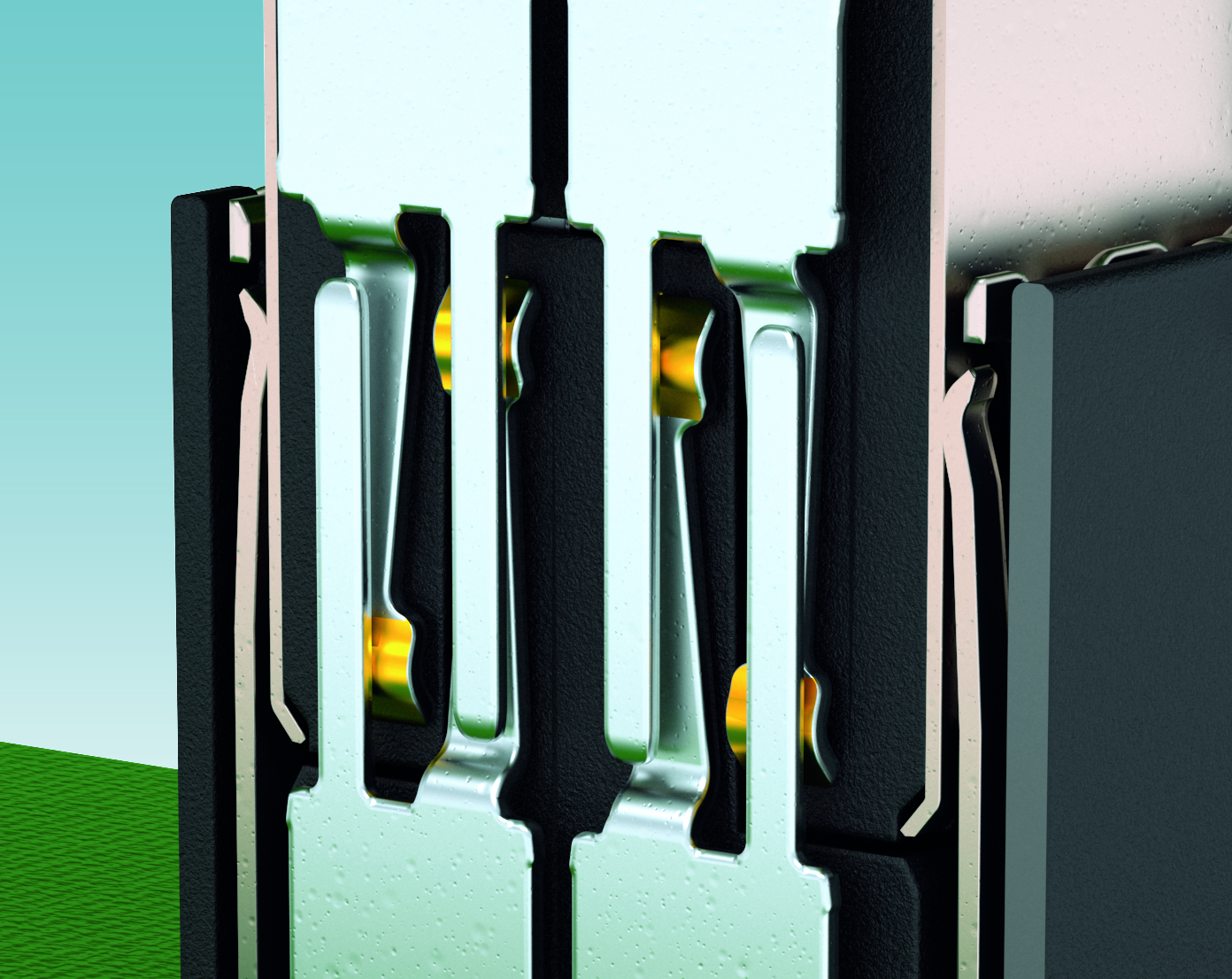

Board-to-board connectors with double-sided contacts guarantee an optimum contact force, even under high shock effects of up to 50g. This robust design also makes it possible to have up to 500 mating and withdrawal cycles without impairing electromechanical stability.

Double-sided contact systems provide high stability and allow for up to 500 insertion and withdrawal cycles.

Unshielded board-to-board connectors with a 1.27mm pitch can be suitable for stacking heights from 8mm to 13.8mm; pre-assembled female connectors with flat ribbon cable can also enable wire-to-board applications, which can help accommodate larger PCB spacings; and compact solutions with a tight 0.8mm pitch can achieve high-speed data transmission of up to 16Gb/s. Depending on the application and the required degree of protection, unshielded versions and versions with lateral shielding mechanisms are available for maximum data integrity. Some of the more compact board-to-board connector offerings include hermaphroditically designed contacts that allow stacking heights from 6mm to 12mm.

Another newly developed contact system not only guarantees particularly high mechanical stability, but also permits high tolerances for male and female connectors positioned differently for production or assembly reasons. These 0.8mm-pitch connectors have a catch range of ±0.7mm per axis with mating angle tolerances up to ±4° in longitudinal direction and ±2° in transverse direction. These high tolerances compensate for the mechanical offset between PCBs.

Simple Solutions for SMT Processes

Modern board-to-board connectors are also often ideally suited for integration into fully automated SMT processes. Specially shaped and tin-plated gullwing surfaces achieve maximum contact area on the solder pads and improve the mechanical stability between the connector and the PCB. The soldering surfaces for such connectors are designed to allow for overhead soldering, which is always necessary when a PCB is assembled on both sides. Unshielded versions can also permit automatic optical inspection (AOI) and be delivered in tape-and-reel packaging for compatibility with pick-and-place processes.

Newer 0.8mm- and 1.27mm-pitch board-to-board connectors provide PCB designers with more flexibility when connecting several PCBs in industrial electronic devices. These robust contact systems also allow for different PCB arrangements and stacking heights, which results in greater support for flexible and modular device designs. As field devices become smaller, more modular, and more intelligent, device manufacturers can obtain tested and reliable device interfaces for the transmission of signals, data, and power from a single source. Thanks to these highly adaptive devices, the intelligent factories that serve as the backbone of Industry 4.0 are fast becoming a reality in markets around the world.