Custom or Off-the-Shelf Medical Connectors?

There are a number of factors to consider when deciding between custom or off-the-shelf medical connectors, and the pros and cons of each might surprise you.

When designing a new medical device, one of the decisions manufacturers face is choosing a connector and mating receptacle. For some applications, a standard (or off-the-shelf) connector is a viable option. For other applications, a custom or hybrid connector may be more appropriate.

When designing a new medical device, one of the decisions manufacturers face is choosing a connector and mating receptacle. For some applications, a standard (or off-the-shelf) connector is a viable option. For other applications, a custom or hybrid connector may be more appropriate.

Reasons to consider a custom medical connector include:

- A unique design is required to ensure that only a specific cable or connector can be mated to the device

- The shape of the connector needs to match the profile of the device

- A variety of signal types must be carried within a single connector (high voltage, low voltage, high bandwidth, data, thermocouple)

- Better able to meet the cost target

- Custom logo or markings are required

- Enhancing safety by preventing mating of incompatible connectors via unique pin-to-socket patterns or connector shapes

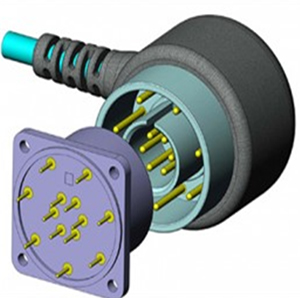

This custom connector fits the contour of the device case.

A custom connector will typically involve engineering and tooling fabrication costs. These up-front charges can be a roadblock to choosing a custom connector solution. However, once the costs for connector design and tooling are realized, a custom connector can often cost much less than an off-the-shelf connector.

Physical Properties

A custom connector solution allows each desired physical property to be addressed. A custom connector can be designed so that mate and un-mate force matches specific customer requirements. This force is composed of the friction from each pin and socket as well as the mechanical interface of the connector and receptacle.

Moisture protection is often a consideration in medical interconnect systems. Off-the-shelf connectors typically incorporate shells and pre-molded boots or collars. When these components are assembled into a finished connector, they often do not offer the required degree of ingress protection. Custom overmolded connectors can be designed with any required ingress protection (IP) rating.

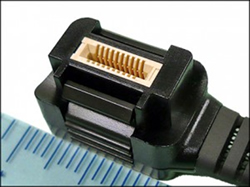

This custom edge-card connector is designed to mate directly with PCB.

Availability of connectors from major manufacturers can also be an issue, with lead times of eight to 16 weeks being common. Once tooling has been fabricated, the lead time for custom connectors can be much shorter than for off-the-shelf connectors.

Design Requirements

Establishing detailed design requirements is one of the first steps in determining whether a custom or standard connector is the best option. Factors that may require consideration include:

- Number and type of contacts (pins or sockets and specifications for each)

- Cable configuration (ECG, defib, power, analog, digital, bandwidth, pneumatic, fiber optic, or combination of two or more)

- Cable diameter, materials, and shape

- Regulatory and environmental ratings (RoHS, REACH, ISO 10993, UL)

- Strain relief requirements

- Shielding requirements for both the connectors and the cable

- Voltage and current requirements

- Size constraints and/or desired physical size

- Ingress protection (IP) requirements or rating

- Number of mate and un-mate cycles required

- Locking mechanism – if any

- Keying requirements

- Desired mate and un-mate force

- Cleaning, disinfection, and sterilization requirements

- Logos, markings, and serialization

Components of Custom Connectors

Keyway prevents non-keyed connector from being mated.

A custom connector typically involves an injection-molded, hard plastic insulator into which pins, sockets, or both are inserted. Termination of conductors to the pins or sockets by solder or crimp is most common. This assembly is then overmolded with a rigid material such as polypropylene, which holds the construction together and provides physical strength. A second overmolding with a material such as a thermoplastic resin or silicone gives the connector the desired color, finish, look, and feel.

Hybrid Connectors

For some applications, a hybrid connector may be the best option. A hybrid connector is an off-the-shelf connector with custom features such as an overmolded grip or strain relief. Design and tooling costs for a hybrid connector can be less than for a custom connector yet the finished product can have the look, feel, and some of the additional performance advantages of a custom connector. In addition to lower engineering costs, a hybrid connector can have a shorter design and development schedule than a fully custom connector design.

A custom or hybrid connector can provide unique features and benefits for medical devices. Each design element can be addressed with less compromise as compared to using an off-the-shelf connector. Safety and reliability can be enhanced and a custom connector may be a more cost-effective solution. However, custom and hybrid connectors typically require a greater investment in engineering and tooling than an off-the-shelf connector.

[hr]

Hank Mancini is the business development manager for Affinity Medical. In his 30-year career in the medical industry, Hank has been exposed to almost every facet of the business, from marketing and manufacturing to new product development, sales, and strategic management. Contact Affinity Medical for more information regarding custom medical connector solutions.

Hank Mancini is the business development manager for Affinity Medical. In his 30-year career in the medical industry, Hank has been exposed to almost every facet of the business, from marketing and manufacturing to new product development, sales, and strategic management. Contact Affinity Medical for more information regarding custom medical connector solutions.