Irregular PCB Configurations Require Small Connectors and Creative Solutions

When a traditional rectangular connector isn’t the right fit for a unique PCB shape, engineers must look for a creative solution. Sometimes that solution is a custom connector that can deliver the needed space savings and the reliability required for mission-critical military applications.

By Jim Murphy, International Sales Manager, Advanced Interconnections Corp.

The demand for smaller, slimmer, and lighter-weight electronic equipment continues to extend across markets, challenging component suppliers to develop connectors with lower profiles, finer pitches, and reduced footprints, and the ability to deliver the same or improved electrical performance and mechanical reliability as their larger predecessors.

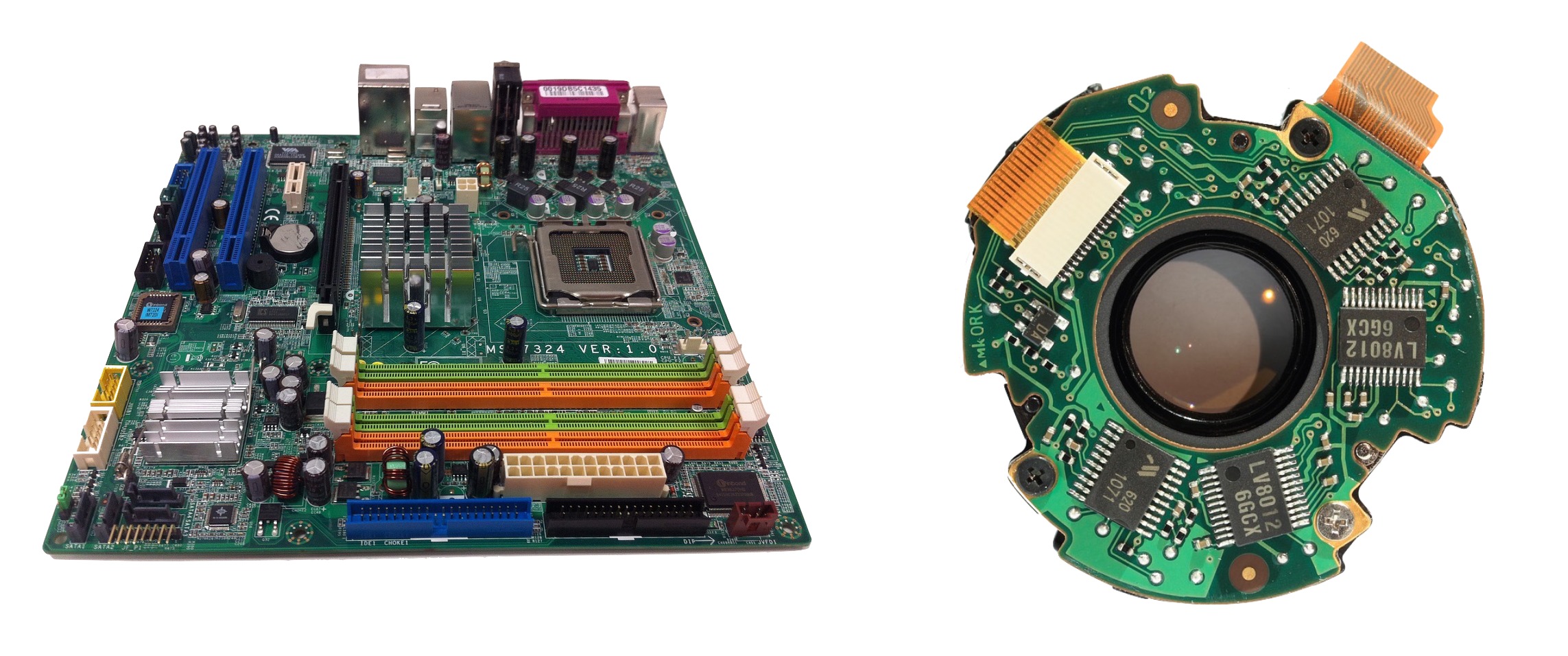

Today’s advanced electronics employ PCBs in a variety of shapes and sizes, sometimes with cutouts, to enable reduced-size end devices. The geometric mismatch between irregularly shaped PCBs and standard rectangular connectors, especially those with lead-frame contacts, can make it extremely difficult or impossible to make efficient use of limited PCB real estate and achieve the high component density typically required by smaller devices.

Uniquely shaped PCBs are becoming more common as trends favor small, slim, and lightweight form factors for advanced electronics

The unique size, weight, and performance demands of high-performance, high-reliability electronics often require customized solutions that can meet the needs of atypical form factors while coming in on budget and on time, while also meeting stringent military standards.

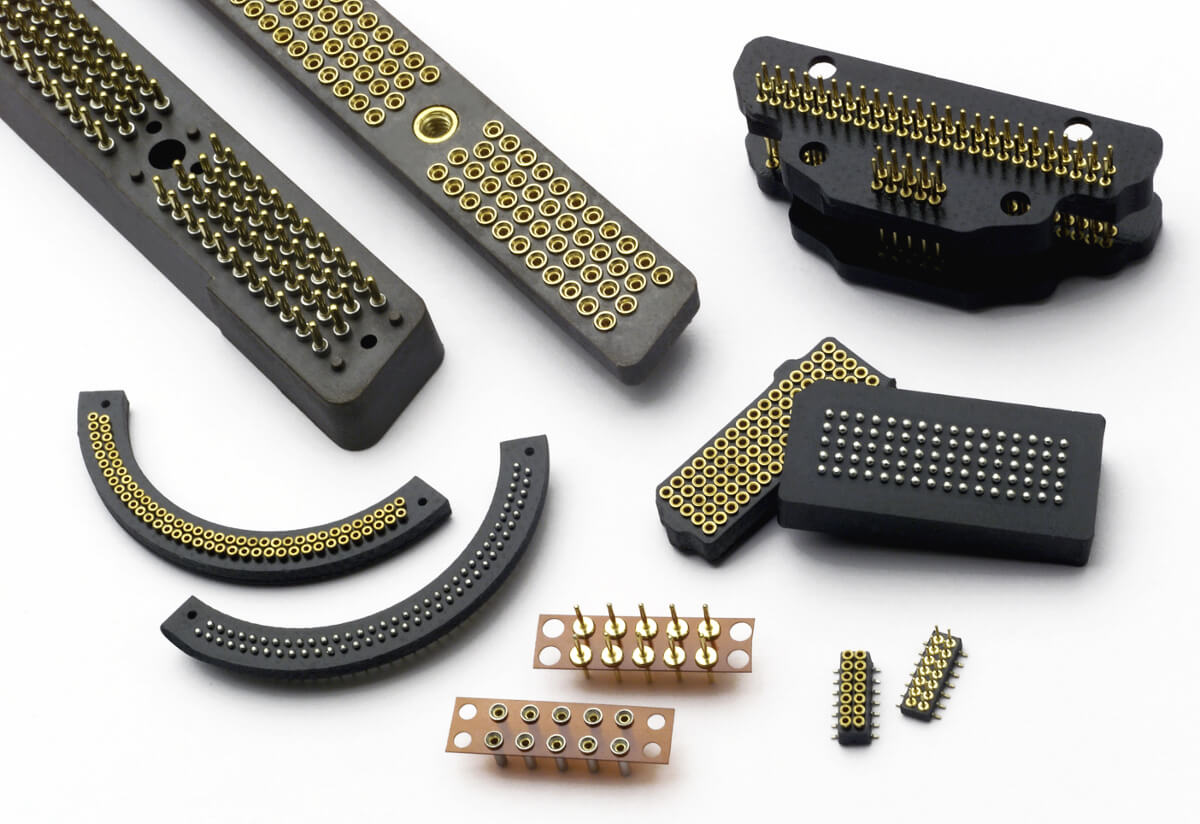

Advanced Interconnections uses in-house precision machinery to create customized board-to-board connectors that solve difficult design challenges quickly, affordably, and effectively.

Case in Point

A military customer approached us with a request for a small, lightweight, and low-profile surface-mount connector that would maximize real estate on a uniquely shaped PCB and meet the rigorous performance and long-term reliability demands of a mission-critical application. They requested keying and polarization capabilities to facilitate blind mating with minimal tooling and setup costs. They also needed a quick turnaround time.

To fulfill this request, our team of design engineers literally thought outside of the box, bypassing traditional rectangular configurations in favor of a semicircular configuration capable of utilizing the perimeter of the PCB. This solution provided both the ruggedness and flexibility required, and achieved a low, 6mm stack height. Board-to-board connectors that utilize screw-machined terminals with multi-finger contacts are ideal for meeting the high-reliability demands and unique design requirements of mil/aero applications, and these designs are typically custom-designed using high-temperature molded, FR-4, or polyimide film insulators with application-specific features such as shrouds, standoffs, or special plating.

To achieve the necessary reliability and overall size reductions, the team employed our field-proven, 1mm-pitch ball grid array socket adapter contact system with a solder ball PCB interface. This contact system’s screw-machined terminals have multi-finger contacts that provide superior reliability and performance over stamped-and-formed pins and can accommodate a variety of low-voltage differential signaling (LVDS) requirements for power, signal, and ground options. The proprietary solder ball terminal design provides a strong solder joint with enhanced elasticity, effectively compensates for minor co-planarity issues between boards, and takes up less space than typical lead-frame technology (e.g., lead-to-trace or PCB pad).

The team then employed one of our easily customizable FR-4 insulators, which eliminate expensive tooling costs since they don’t require a mold. This choice, along with our field-proven, fine-pitch BGA socket adapter terminals, ,allows for multiple design revisions and fast prototypes during the development phase.

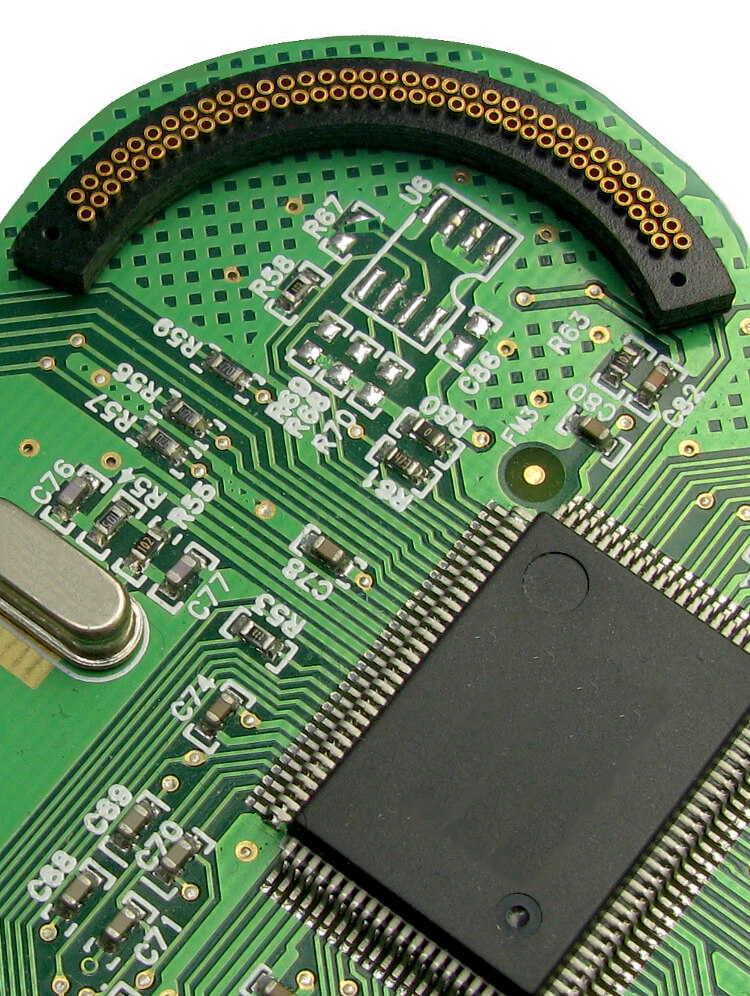

Once the design was complete, the engineers used CNC machinery to create rough samples for electrical and mechanical testing, achieving a custom, ready-to-test prototype in a span of less than five days. Created from FR-4 on an in-house driller/router machine, the prototype connector incorporated 1mm-pitch solder ball terminals on both the male header and the mating female socket and alignment pins for a fully keyed and polarized solution that could facilitate blind mating. Vertical integration and existing screw-machined terminal designs eliminated the need for expensive tooling and set-up costs, such as stamping dies, which made the custom solution a quick and affordable way to satisfy a range of unique application requirements.

Based on Advanced Interconnections’ 1mm-pitch ball grid array socket adapter contact system, these custom SMT Perimeter Connectors achieve a low, 6mm stack height and provide the field-proven reliability required for a mission-critical military application.

By leveraging in-house engineering expertise, field-proven interconnect technology, and precision machinery, we were able to satisfy the six key specifications for the custom military application:

- Mission-critical reliability

- Maximized real estate on a rounded PCB

- Keying and polarization capabilities

- Lightweight, low-profile form factor

- Minimal tooling and set-up costs

- Quick turnaround time

Our rugged, 70-position SMT Perimeter Connector successfully maximized real estate on a semicircular PCB with a compact, lightweight, and low-profile housing that attached along the perimeter of the board with space-saving solder ball terminals, prevented mismating and enabled blind mating with keying and polarization features, and delivered the high electrical and mechanical reliability required for a mission-critical military application. This solution was developed, start-to-finish, both on budget and within a single workweek. It was also designed with flexibility in mind and can quickly and easily be reconfigured to meet future board revisions in the same or another similar application with the same proven performance, low overall cost, and short turnaround time.

Visit Advanced Interconnections Corp. online.