Laser Wire Stripping for Medical Device Manufacturing Applications

Pete Doyon, VP, Product Management, Schleuniger, Inc.

NASA developed laser wire stripping in the 1970s as part of the Space Shuttle program. This technology made it possible to use smaller sized wires with thinner insulations without the risk of the damage that can be caused by traditional mechanical wire stripping methods. Laser wire stripping technology was commercialized in the 1990s, and was initially used for aerospace and defense applications. However, it grew significantly when the consumer electronics market exploded, as lasers became the only suitable stripping solution for the tiny data cables found in laptops, mobile phones, and other portable consumer electronics products. Another large industry that has adopted laser wire stripping methods, and for good reason, is high-end medical device manufacturing.

The Benefits of Laser Stripping

Using laser light to remove insulation or coating layers from electrical wires, catheters, and other medical devices is now the norm due to the many benefits that laser stripping processes provide for medical device manufacturing. The most important of these is the highly repeatable quality that is inherent to the process. When using a CO2 laser to strip polymer insulation, from a wire conductor for example, the laser energy is readily absorbed by the insulation, but highly reflected by the underlying metal conductor. Since the conductor reflects the laser light, there is no risk of damaging it during the stripping process. With laser stripping, there are no limits to how small of a wire can be stripped and, no matter the wire size, there remains no risk of damaging the conductor.

Another benefit is that laser stripping machines can strip round, out-of-round, and flat ribbon, as well as any other shape of wire or cable. Stripping geometries include: end stripping, window stripping, slitting, or complete area ablation. The laser stripping process is also very user-friendly. There are no blades to change or consumables to replace, in contrast to mechanical stripping methods. Additionally, the process is non-contact, so there are no elements that will wear out or require frequent maintenance or replacement.

Laser stripping machines are also very versatile. There are many different laser types on the market, each with a different wavelength. The idea is to select a laser with a wavelength that is readily absorbed by the layer you want to remove (i.e., strip), yet is strongly reflected by the underlying layer.

Further, laser strippers can be used in both semiautomatic and fully automated processes. In semiautomatic processes, an operator simply presents the material to be stripped to the machine. This is typically used for end stripping, and can be used for single ends or a batch at a time. Similarly, laser strippers can be fully integrated with a downstream cut-and-strip machine to measure, cut, and strip in a fully automatic process.

Types of Medical Applications for Laser Stripping

In medical device manufacturing, selecting the correct wires and cables for the job and properly processing them is of extreme importance. In some cases, it can even be the difference between life and death. Laser wire stripping can ensure higher quality processing for multiple medical applications.

Catheter Wiring

Catheters are used to guide a medical probe or device to specific tissue within the human body, so the highest demands are placed on reducing wiring size to improve maneuverability and increase functionality. Typical applications include RF ablation, where the catheter carries multiple conductors, including a number of thermocouples, as well as the RF ablation signal. This fine wiring tends to be manufactured using either enamel (e.g., polyimide) coatings or biocompatible fluoropolymers, and can easily be nicked when using traditional mechanical stripping methods. However, since the conductors of even these ultra-miniature wires will reflect the laser, laser wire stripping ensures a 100% nick-free strip.

Figure 1: Laser stripping is a perfect solution for stripping extremely small catheter wires.

Pacemaker Electrodes

The flexible, spring-like electrodes in pacemakers pose special challenges to laser ablation due to their fluoropolymer coatings and sensitivity to heat during processing. However, those challenges can easily be overcome with the proper laser selection and processing technique, so laser stripping is still a viable and attractive option.

High Performance Motor Windings

Medical power tools, such as the drills used in brain surgery, must have the highest levels of quality and reliability. Using traditional mechanical brushing and abrading processes on the enameled motor windings in these tools can introduce dangerous particulates into the end product. Laser stripping, on the other hand, offers a clean, risk-free alternative.

Hypodermic Tubing Coatings

Hypotubes are long metal tubes with micro-engineered features along their length, and are a critical component of the minimally invasive catheters used in conjunction with balloons and stents to open up clogged arteries. The balloon portion of these catheters is attached to the head of a hypotube. When manufacturing such devices, it is necessary to remove part of the extruded coating (e.g., PTFE-, ETFE-, or nylon-based compounds). Laser removal is proving to be a popular alternative to more traditional blade based methods, primarily due to the ability to automate the process, which can save time and money, as well as mitigate mistakes.

Fine Wire Applications

Small gauge single conductors are extremely common in medical devices ranging from catheter delivered devices to cochlear implants and hearing aids. With laser stripping technology, wires as small as 50AWG and smaller can be stripped without damaging the conductor.

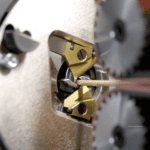

Micro-Coaxial Ribbon Cables

Flat micro-coaxial ribbon cables are found in a great number of medical device interconnects. Ultrasound machines are a classic example. This application requires high-density, high-frequency signals to be transmitted through the most flexible cabling possible, dictating the use of ultra small conductor sizes in high-density micro-coax ribbons. Due to the extremely small wire size and high level of precision required, laser stripping is again an ideal solution, as it guarantees high-quality results in ultra-small, critical application cables.

Figure 2: Micro-coaxial ribbon cables, such as those used in ultrasound machines, have small, flexible wires that prove difficult for traditional stripping methods.

The Future of Medical Device Manufacturing

The medical device manufacturing market employs an array of incredibly small, complex, and delicate wiring systems that are subject to stringent quality and performance requirements. Laser wire stripping readily meets many of the challenges of this uniquely demanding industry, and will continue to be the stripping method of choice as ever smaller and more delicate medical devices continue to evolve.