PCB Terminal Wiring Made Easier

PCB Terminal Wiring Made Easier

PCB Terminals – Quick ConnectionTechnology at a GlancePush-in Spring Connection The push-in spring connection technology brings together the advantages of the leg spring and tension spring. This means that the wire can be connected directly without the use of additional tools. The fixed-cage housing of the combined spring prevents the wire from slipping to the side. As a result, the push-in spring allows tool-free connection with moderate effort, especially with large cable cross-sections. Push-lock Spring Connection The patented push-lock spring, based on the one-hand tilting lever principle, permits the easy and tool-free connection of a cable ― with or without ferrules. The rigid or flexible conductor is simply inserted into the open terminal point and is securely closed by actuating the release lever via the push-lock spring. Alternatively, the conductors can be directly inserted with the lever closed, using push-in technology. |

Manufacturers of high-current applications know a variety of ways to transfer power to PCBs. Common approaches include busbars with complex wiring and installations with ring cable lugs or external wiring. However, those methods can be cost-intensive and time-consuming. PCB terminals with quick connection technology offer an ideal alternative, as they allow cables to be connected quickly, safely, and without tools in a wide range of applications.

Manufacturers of high-current applications know a variety of ways to transfer power to PCBs. Common approaches include busbars with complex wiring and installations with ring cable lugs or external wiring. However, those methods can be cost-intensive and time-consuming. PCB terminals with quick connection technology offer an ideal alternative, as they allow cables to be connected quickly, safely, and without tools in a wide range of applications.

Device manufacturers face an ongoing challenge: With each new generation, their devices must be more compact and less expensive, while at the same time more powerful and service-friendly. For this reason, more and more components and functions are being placed onto powerful PCBs. In the case of high-current applications, PCBs are often used in multilayer configurations. This requires an accompanying connection technology. Press-in technology is still used with currents above 20A, where massive contact elements are pressed onto the PCB. However, this approach has a significant drawback in that it takes place in a separate operation, along with soldering, and the massive contact elements must be connected with ring cable lugs.

More Convenient Options

An excellent alternative to press-in technology is the PCB terminal with screw connections that uses tension-sleeve technology. This connection principle, in successful use for decades, enables transmission of a current of up to 125A, depending on the product line. But there is a key disadvantage in this case as well: The cable must be connected using a screwdriver at a predefined torque. In industrial settings, where time and costs are very important, the PCB terminal with quick-connection technology appears to be the ideal alternative. It allows quick, low-cost, and, most important, easy connection of the cables.

Two different quick connection technologies are common: Push-in and push-lock spring connections (see sidebar). The push-in spring connection technology is the optimal connection for pre-assembled flexible cables with ferrules, such as internally wired devices. The cable can be directly inserted into the terminal point without any tools. The spring helps to establish a secure contact. This also removes the risk of an incorrect-locking torque for the terminal point, a potential source of errors that may occur in industrial series production.

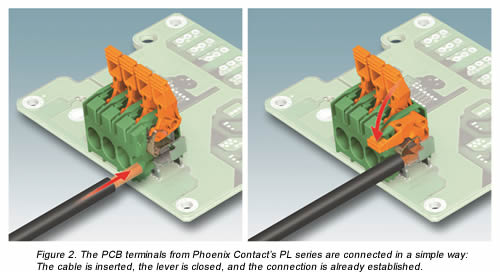

Another quick-connection technology is the push-lock spring cage connection. It is based on the “one-hand tilting lever principle” and permits the easy and tool-free connection of the cable ― with or without ferrules. An intuitive stepped lever, typically orange in color, can make operation a snap. This operating principle is well suited not only for the factory wiring of devices, but also for field wiring. If the PCB terminal is delivered open, during on-site wiring, the installer simply needs to close the lever after inserting the conductor. This function saves time when connecting a conductor (Figure 2). In addition, with the lever closed and using push-in technology, this type of plug-in connector can be wired with either solid wire or stranded wire with a ferrule.

Another quick-connection technology is the push-lock spring cage connection. It is based on the “one-hand tilting lever principle” and permits the easy and tool-free connection of the cable ― with or without ferrules. An intuitive stepped lever, typically orange in color, can make operation a snap. This operating principle is well suited not only for the factory wiring of devices, but also for field wiring. If the PCB terminal is delivered open, during on-site wiring, the installer simply needs to close the lever after inserting the conductor. This function saves time when connecting a conductor (Figure 2). In addition, with the lever closed and using push-in technology, this type of plug-in connector can be wired with either solid wire or stranded wire with a ferrule.

Both connection technologies ― push-in and push-lock ― are available in products with a current range up to 76A and a cable cross-section of 16mm2. Current spring-connection terminals on the market are available to connect either horizontally or vertically. In addition, a bridgeable version can be placed at an angle of 30° to the PCB (Figure 3), for further design flexibility. Push-in terminals currently come with horizontal connections, with the 41A version also available at a 30° angle to the PCB.

Coding Options Prevent Errors

Coding Options Prevent Errors

In the industrial world, wiring often takes place under time pressure. To avoid wiring errors, PCB terminals with a labeling and printing surface make it easy to correctly match the cables to the corresponding terminal points. Furthermore, the housing can be color-coded from pin to pin, thanks to the individual wafer configuration (Figure 4). Some manufacturers will also supply a customized, multi-pin PCB terminal in different colors to meet the customer’s specific needs. For example, the customer might choose the colors of the cables to be connected.

In an industrial setting, PCB terminals featuring quick connection technology are the ideal alternative to standard connection technologies, due to more efficient and intelligent wiring. Thanks to the faster assembly times and lower costs, the use of quick connection technology will only become more popular among device manufacturers.[hr]

By Thorsten Rosin, Product Marketing Device Connectors, Phoenix Contact GmbH & Co. KG and James Dunbar, Product Marketing Manager, Phoenix Contact USA