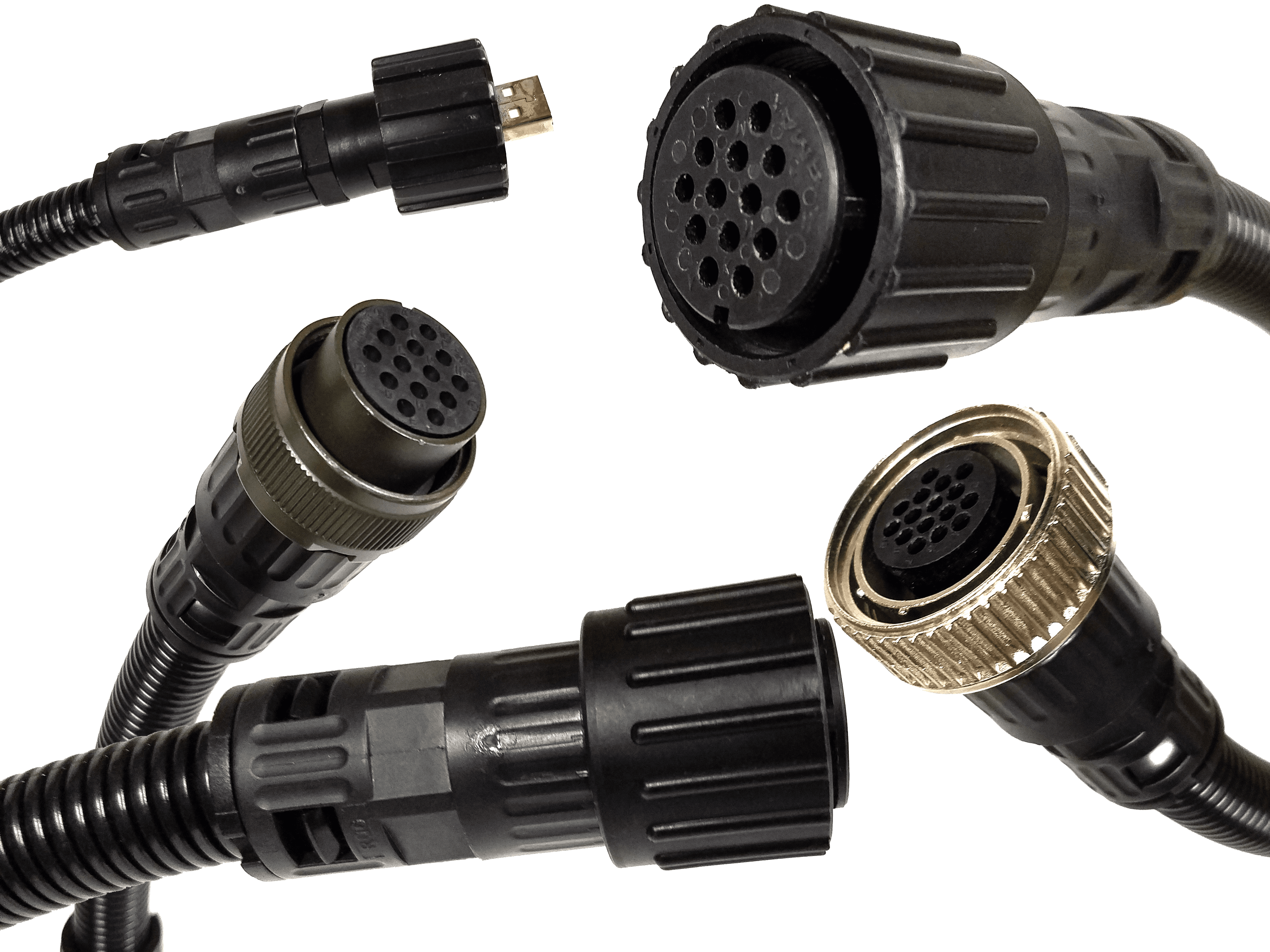

Polyamide Cable Protection Systems Provide High-Reliability Solutions for MIL-C-5015 Connectors

Specialized conduit systems designed to adapt to MIL-C-5015 style connectors are available in several different highly engineered formulas to suit a variety of rugged military, aerospace, and industrial application demands.

By George Sims, Director of Marketing, AerosUSA

High-quality cable protection solutions are now available for MIL-C-5015 and UNEF-threaded connectors. These connectors traditionally come with backshells and clamps designed to latch onto control cables. So, in the past, attaching them to liquid-tight or other protective conduits required custom, specially machined adapters that significantly increased overall project costs. To avoid these additional costs, many engineers used heat-shrink tubing, glue, hose clamps, and other gadgets to adapt these connectors to protective conduits. These alternative solutions were less costly than machining custom adapters, but their reliability was questionable, as it was almost exclusively based on individual installer’s experience.

In recent years, several manufacturers of polyamide cable protection systems have not only released specialized conduit systems designed to adapt to MIL-C-5015 style connectors, they have made these solutions available in several different highly engineered formulas to suit a variety of rugged industrial application demands. The most common specially formulated polyamide conduits include extremely flexible PA12 conduits for continuous motion applications, such as robotics or cable tracks; high-strength PA6-D impact- and compression-resistant conduits for outdoor and factory floor applications; high-temperature PA6-HT conduits for projects requiring temperatures up to 200°C; and UL 94 V-O PA6 conduits with self-extinguishing, low smoke, low toxicity, and fire-safe properties for applications in which human safety is a concern, such as subway cars and transport vehicles. These types of applications employ large numbers of commercial grade MIL-C-5015 connectors and, before the widespread availability of compatible polyamide cable protection systems, were known to stress the limits of traditional liquid-tight conduits, sometimes to the point of failure.

Polyamide cable protection systems for MIL-C-5015 and UNEF-threaded connectors are now available in several different highly engineered formulas to suit a variety of rugged industrial application demands.

In addition to sparking the development of the various polyamide cable protection systems described above, the increased demand for commercial 5015-style connectors in industrial applications, combined with the need to provide proper protection for associated cabling, also led to the development of UNEF-threaded fittings designed to mate directly to the UNEF threads found on the backshells of MIL-C-5015 connectors. These fittings now provide critical IP66, IP68, and IP69K protection for polyamide conduit systems.

Female UNEF-threaded fittings are characterized by outstanding resistance to high impact forces and submersion, and, for IP69K versions, the ability to withstand 1450psi high pressure direct spray. Their ability to mate with the UNEF threads found on traditional MIL-C-5015-style circular connectors and their compatibility with a wide selection of polyamide conduits allows for a nearly unlimited number of effective, protective solutions that can be customized to suit nearly any industrial application. Designed for use in interior and exterior applications with high impact strength and flexibility demands, these fittings are also ideal for applications that need to secure conduits and cables of various sizes. This is accomplished through the use of specialized Y and T adapters that can eliminate the need for a junction box and make for a compact, lightweight, ruggedized cable management system.

The widespread availability of various formulations of polyamide conduits designed for UNEF and MIL-C-5015 connectors allows for a nearly unlimited number of effective, protective solutions that can be customized to suit nearly any harsh industrial application.

UNEF-threaded fittings are manufactured from high-grade, specially formulated polyamide materials. They are widely resistant to acids and solvents, free of silicone, cadmium, and halogen, Reach and RohS compliant, and have excellent flame-retardant and self-extinguishing properties. Applications include military vehicles, radar systems, portable military shelters, airport lighting systems, satellite communication systems, tactical training systems, training simulators, subway cars, locomotives, machine tools, automated control systems, robotic equipment, packaging and conveying equipment, and wherever MIL-C-5015 connectors are used.

Polyamide fittings from most manufacturers are available with IP66, IP68, and IP69K ingress protection, and a select few offer integrated seals and locking mechanisms built into the fittings to consistently ensure quick, easy, trouble-free connections. These female-threaded fittings are also available with metric, PG, and NPT threads capable of mating with ENT pipe, sensors, and other male-threaded devices, and are typically available for use with conduit sizes OD 10.0mm (1/4’’) to OD 54.5mm (2”). Some manufacturers also have the ability to conveniently add EMI/RFI protection by offering a clean and simple way to terminate the shield to the conduit fitting and mil-style connector. These features and benefits make them ideally suited for mil/aero applications and demanding industrial applications that require quality cable protection systems for MIL-C-5015 and UNEF-threaded connectors.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation