Powerful e-Textiles Promise Washable, Wearable Connectivity

Small, lightweight, and wearable doesn’t cut it for designers of e-textiles. New flexible, conductive fabrics make wearable electronics even more comfortable and connected.

The continuous downscaling of connectivity products has opened up new possibilities in the world of e-textiles. In this emerging area of electronic design, engineers have moved beyond small and lightweight wearables that can be attached to a person’s body or clothing; the next frontier is clothing and other fabric items that are electronic devices. Micro-fine conductive fibers, nano-miniature sensors and batteries, and new PCB printing technologies have made it possible to design flexible, stretchable, washable, compressible, and shapable textiles. This field has already produced applications such as gloves embedded with haptic sensors, smart bandages and other medical fabrics, and garments that can provide heat or emit light. Numerous concepts are in development for automotive, sports, space exploration, and fashion applications.

Industry organizations such as the E-Textiles Network, an international group dedicated to the development and adoption of e-textile technologies, are working to share knowledge, raise awareness, and solve challenges in this rapidly growing field.

Engineers working in the e-textile field share research through the E-Textiles Network to improve industry knowledge about energy harvesting, washability, weaving and printing technologies, and potential capabilities that future smart fabrics will be able to offer medical, military, and consumer users.

In 2020, IPC established the first standard for e-textiles, IPC-8921, Requirements for Woven and Knitted Electronics Textiles (e-Textiles) Integrated with Conductive Fibers, Conductive Yarns and/or Wires. This standard establishes classifications and designations for woven materials and knitted e-textiles integrated with e-fibers, e-yarns, and e-wires. It also standardizes key characteristics, and outlines methodologies for durability testing and quality assurance. Under the standard, e-textile products must meet these key characteristics: electrical resistance, electromagnetic immunity, thermal conductivity, coefficient of thermal expansion (CTE), specific heat capacity, thermal shock resistance, outgassing, glass transition temperature (Tg), and established melting point.

Connected fabrics and e-textiles incorporate connectors, cables in fiber form, sensors, transmitters, and power source connectivity, including batteries and solar energy collection systems. The most common data communication methods for interactive textiles are Wi-Fi and Bluetooth.

JAE’s RK01 Series Smart Textile Connectors can be integrated into clothing that measures and detects biodata on performance and well-being for sports, medical, and other purposes.

Connector suppliers are delivering new products for e-textile designs. JAE’s RK01 Series Smart Textile Connectors have been developed for use in smart clothing and medical textiles. Matsunaga Akihiro, senior connector design engineer at JAE, said that designers are particularly focused on the potential e-textile materials offer to designers of medical products. The aging of Japan’s society has inspired a wave of innovative medical products, including smart socks, bandages, and compression garments. “Clothing-type medical devices can acquire medical-level biomedical and advance information about the human body, including fingertip data and motion sensing for the whole body, which can be utilized by the IoT,” he said. E-textiles offer more precise data than traditional wearable electronics, because the textiles can be worn closer to the body and gather more nuanced data about muscle, respiratory, and heart activity. “This information is difficult to realize with data obtained from a smart watch or other wrist-worn products.”

JAE’s RK01 series can be connected to conductive fibers or ink equipped with sensors that enable data to be collected from multiple biological data points, delivering information about heart rate, respiration, temperature, and whole-body motion. The RK01 consists of a plug connector that terminates in an article of clothing made from conductive e-textiles, and a socket contact mounted to a PCB inside a removable transmitter. The plug connector consists of a pin contact, top insulator, and bottom insulator. The connecter is mated using a click-into-place tactile action similar to snaps worn on clothing, making it user-friendly for a wide variety of people. The plug connector that is worn on the clothing side is also waterproof and machine washable.

Waterproofing is a critical feature of textiles that are to be worn closely to the human body, such as medical products, sportswear, and clothing for soldiers. These electronics must resist damage or interference from sweat or the elements, as well as the more intense agitation of machine washing. Connection points between conductive fibers and the connector must be sealed and rugged. Some future designs may eliminate cable-type fibers or yarns in favor of printed circuitry.

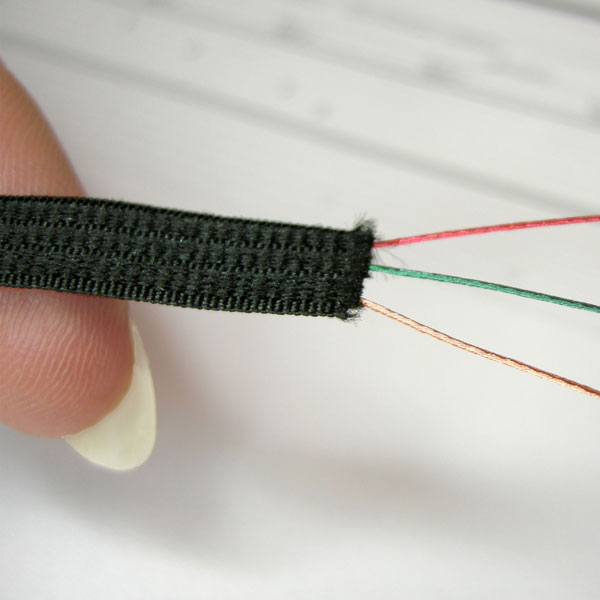

Traditional textile properties such as flexibility, texture, colorfastness and washability are preserved in conductive ribbon cables by Ohmatex.

In the meantime, an expanding range of conductive fibers, cables, and ribbons are being woven into soft, flexible textiles. Ohmatex offers textile cables and ribbons that include coaxial cable, stretchable sensors, and other features. These cables can terminate to a PCB or a connector, including a standard jack connector or what the company says is the world’s thinnest micro-USB. The company is creating solutions for use in wearable computing products for astronauts on the International Space Station.

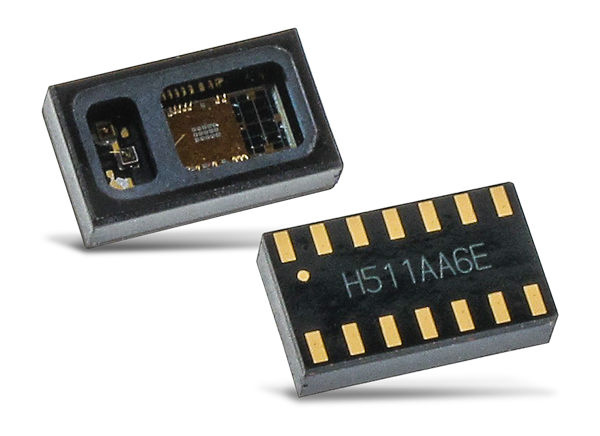

The Maxim Integrated MAX30102 Sensor, available from Mouser Electronics, is an integrated pulse oximetry and heart-rate monitor module. The MAX30102 includes internal LEDs, photodetectors, optical elements, and low-noise electronics with ambient light rejection.

In addition to innovative connector and cable products, new sensor technologies make powerful e-textile products possible. Embedded capacitive, resistive, and optical sensors enable the textile to measure touch, strain, pressure, temperature, humidity, and other data. Sensors can be woven into textiles or printed upon them.

E-textiles also need a power source. Rechargeable products can be attached to a battery or charging device after use. Some products may integrate thin, flat, and flexible batteries that are able to survive washing processes. Textile solar panels made from solar e-yarns can harvest energy directly from the sun, eliminating the need for recharging while retaining the wearability features of textiles. These self-powering e-textiles have great potential utility for sportswear as well as expedition gear and workwear for harsh-environment job sites.

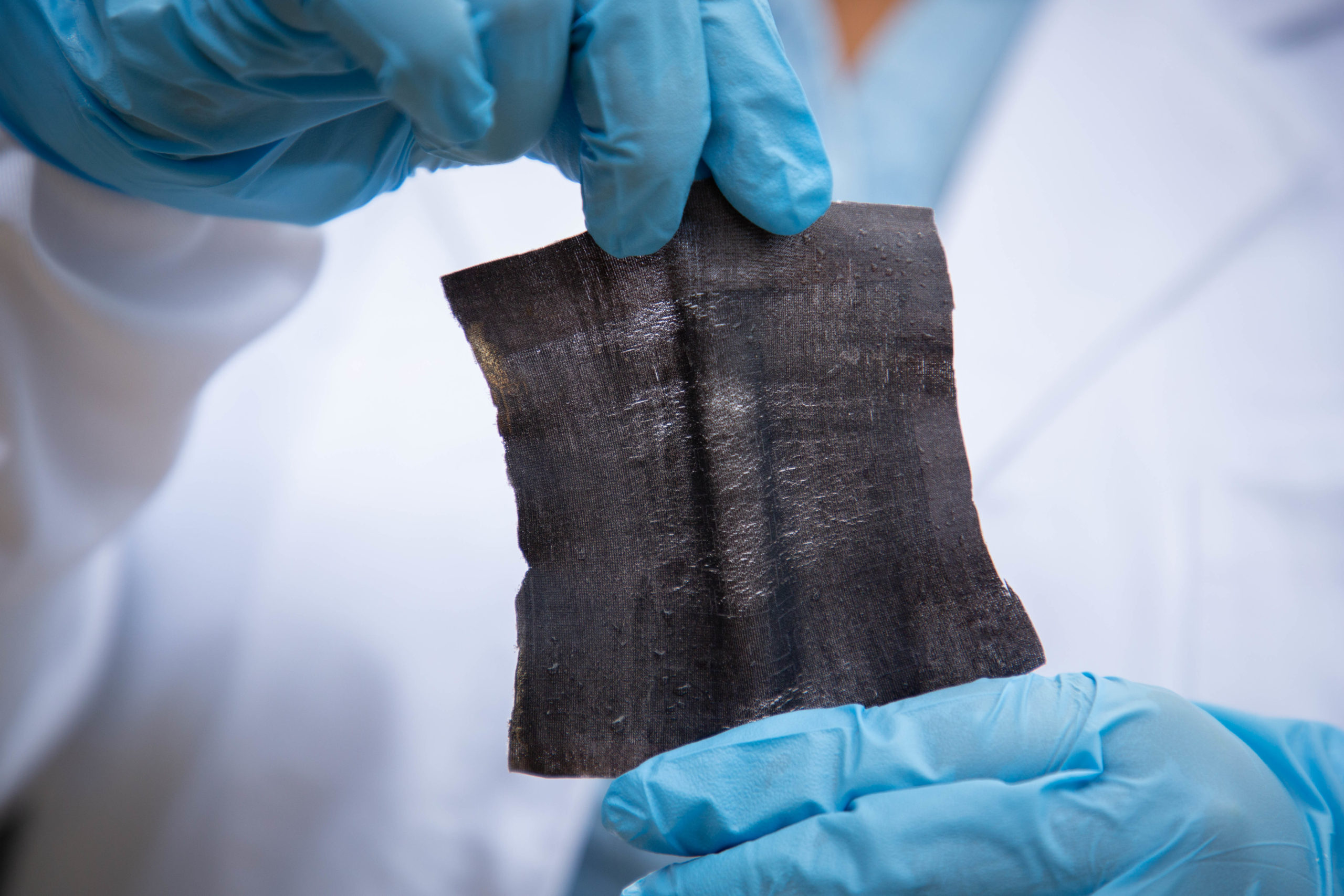

Scientists from Royal Melbourne Institute of Technology (RMIT) say the next generation of waterproof smart fabrics will be laser printed and embedded with energy storage devices. They have developed a new technology that enables graphene supercapacitors — powerful and long-lasting energy storage devices that are easily combined with solar or other sources of power — to be laser printed directly onto textiles. Litty Thekkakara, a researcher in RMIT’s School of Science, said smart textiles with built-in sensing, wireless communication, or health-monitoring technology requires reliable energy solutions.

Smart textiles developed by RMIT use a laser printing technology to embed textiles with energy-harvesting technologies.

“Current approaches to smart textile energy storage, like stitching batteries into garments or using e-fibers, can be cumbersome and heavy, and can also have capacity issues,” Thekkakara said. “These electronic components can also suffer short-circuits and mechanical failure when they come into contact with sweat or with moisture from the environment. Our graphene-based supercapacitor is not only fully washable, it can store the energy needed to power an intelligent garment – and it can be made in minutes at large scale.”

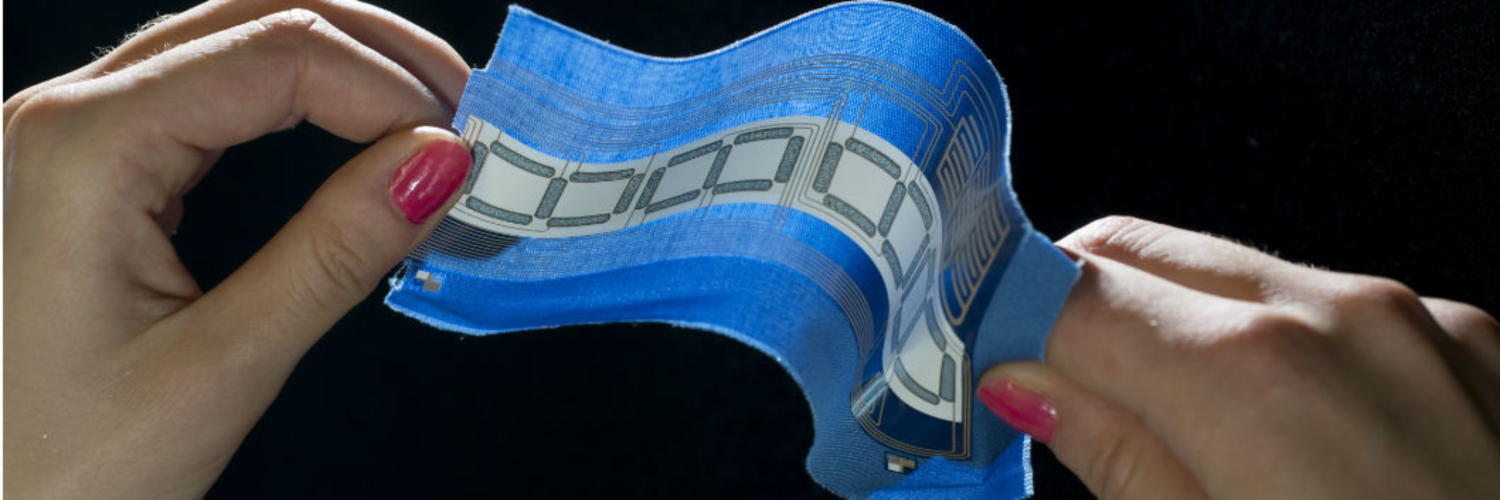

Instead of weaving a textile using conductive fibers, advanced printing technologies have created new strategies to make fabrics conductive, such as applying inks printed onto a stretchable substrate. Particle-free inks are well suited to directly printing on textiles. Unlike flake-based stretchable inks, their low viscosity and lack of particles enables particle-free inks to permeate textile fibers. The ink is metalized by curing, making the fibers they have been printed upon conductive, while retaining the breathability and stretchability of the original fabric.

Development in the area of e-textiles is only beginning. The arrival of nano-sized and smaller connectivity products that can deliver performance and reliability in a flexible, stretchable, and washable form has opened up new areas of innovation.

Like this article? Check out our other Connector Basics, and New Technology articles, our Consumer Electronics, Sensors/Antennas and Medical Market Pages, and our 2021 and 2020 Article Archives.

- Meet the Connector: DIN Standard Connectors - April 16, 2024

- Software-Driven Radio Reinvigorates Old Technology - April 9, 2024

- What is a Busbar? - April 2, 2024