Press-Fit Technology for Automotive Applications

Press-fit technology is widely applied in multiple automotive applications because it meets the needs of smaller, lighter, more durable components in the latest vehicle designs.

The TE single-pin insertion ACTION PIN inserted into a PCB

The basic principle of a press-fit connection is that a contact terminal is pressed into a printed circuit board (PCB). There are two types of press-fit pins – the solid pin with a solid press-in zone and the compliant pin with an elastic press-in zone. In this article, we’ll discuss the elastic press-in zone.

Press-fit technology is widely applied in multiple automotive applications. Basically, there are two options to consider – press-fit contact terminals (for single-pin insertion) and connector modules (for mass termination). The press-fit terminals for single-pin insertion usually are supplied in a reeled condition that allows the customers to apply the contacts to the PCBs in a “free” and highly flexible manner. Connector modules commonly feature customized housing components equipped with contacts (and other sub-components) in a potentially modular way according to the specific customer needs.

Market Trends

Trends driving product development for the automotive market include:

- Increased electronic content – Between 2011 and 2016, the amount of electronics in vehicles is expected to grow year over year, as intelligent bus systems replace simple cable connections and intelligent distribution boxes replace simple ignitions. Integrated information systems and computerized motor control management will enhance safety, performance and comfort. This increase in electronics will require an increase in electrical connections as well.

- Miniaturization – Vehicles are becoming smaller, safer, cheaper, and better. Most new applications are controlled by electrical control units (ECUs) that need to be as compact as possible. Inside each ECU there is a PCB carrying the electrical components which is shrinking in size as well. Therefore, more electrical interconnections are required on the same or even smaller packaging space. This drives the development of miniaturized interconnect components.

- Harsh environments – More demanding environmental conditions and increased functional performance push the electrical interconnections, including press-fit contacts, to be more reliable. Also, with more electrical interconnects, the requirements on each single component increases as the functionality over a lifetime must be ensured for improved quality and reliability.

- Thinner PCBs – While today the most common PCB thickness in automotive applications is 1.6mm, in future applications we may see PCBs down to 1.2mm, 1.0mm, or 0.8mm thicknesses. Press-fit solutions must be developed to meet these new board sizes.

Press-fit Versus Soldering

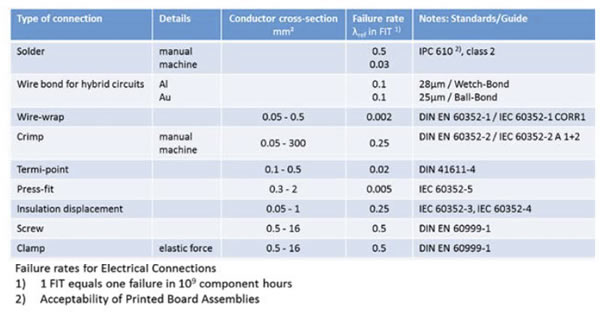

Table 1: Reliability table shows comparison between different electrical connector technologies.

With the conversion to lead-free soldering, an increase in the average soldering temperature is required. To cope with this higher temperature, special and more expensive plastic materials like LCP, PPS, PPA, and PCT are needed. This can be avoided by using press-fit technology rather than the soldering process. In that way, no expensive high-temperature plastics are needed for a lead-free application. As space is an important factor in automotive applications, the press-fit technology provides a solution in the miniaturization of boards, which would be very difficult to realize with a conventional soldering process.

Press-fit technology is especially good for big connectors in combination with a reflow soldering process. Large soldering headers often disturb the surface-mount reflow process. The temperature of the pins of the header and neighboring components can drop too low, resulting in a defective soldering process. This problem can be solved by adding the header after the soldering process by utilizing press-fit technology.

The press-fit pin insertion process is a fast, cheap, and reliable manufacturing process that allows a repair of the press-fit pin up to two times.

Another important aspect of press-fit technology is reliability. The press-fit connection is considered one of the most reliable connection techniques. The reliability shown in the IEC1709 norm shows that the press-fit connection has a fit rate of 0.005, which is at least 10 times more reliable than soldering or IDC connections.

How to Use Press-Fit Technology

Press-fit technology can be used in several ways.

A standalone pin is the most basic method of using press-fit technology. The pins are inserted individually into the PCB by means of automatic equipment. The contact terminal has a shoulder geometry, which provides the necessary support to press the pin into the PCB. For standalone pins with 5mm pitch, insertion rates up to five pins per second can be reached with some insertion machines.

One of the most common methods of using press-fit technology in automotive applications is a press-fit pin header, which is an assembly that consists of a plastic housing and contact terminals. Typically, these pins are assembled using stitching or an overmolding process. The mating direction of the pin header can be parallel (90°), angled, or perpendicular (0°) to the printed circuit board. Depending on the annual numbers needed, the pin header assembly is done with a manual, semi-automatic, or automatic connector seating machine. The pin header is mounted onto the PCB by pressing on the shoulders of the press-fit pins. There are also applications where you press onto the plastic material of the pin header to mount it.

Another form of application, which is quite common with press-fit technology, is an integrated housing or module. Coils, capacitors, actuators, and sensors are some examples of the possible elements that can be integrated into the same housing while sharing a single PCB.

Benefits

Press-fit technology is a solderless termination enabling a permanent electrical and mechanical terminal-to-PCB connection with several distinctive advantages:

- Fast processing

- Use of standard resins instead of cost-intensive, heat-stabilized resins in the header

- Prevents thermal treatment to the header

- Flexible application designs with single-pin insertion due to freely programmable pin arrays

- Standalone pin insertion possible

- Lubrication- and flux aid-free processing

- Prevents solder paste printing and pre-heating

- Environmentally friendly

- No shading-off issues with large header components in post-soldering insertion

- Prevents soldering defects like bridges, bad wetting, flux residuals, solder balls, spider webs, thermal load, and cold solder joints

Press-fit technology can offer many benefits that match current trends in the automotive market. Potentially, it can be used in every contact-to-PCB connection.

To read this white paper in its entirety, click here.

Authors Joakim Mattsson, Thorsten Callies, and Bart Kerckhof all work for TE Connectivity.