Regenerative Braking Systems in Rail Applications

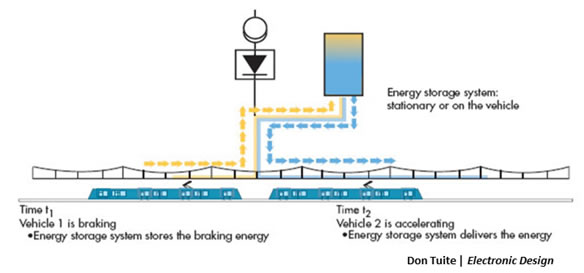

Regenerative braking systems reclaim and store kinetic energy in a reusable manner.

Conventional vehicle braking systems convert kinetic energy into heat via friction, wasting a great deal of energy potential. Regenerative braking systems reclaim and store this kinetic energy in a reusable manner. More and more modern electric drive vehicles, including locomotives, boast regenerative braking systems to capture and apply this available form of power.

Benefits of Regenerating Electricity

Simplistically, electric vehicles use their drive motors to convert kinetic energy into electromagnetic energy. Since motors and generators operate under the same principle, they can be used interchangeably.

The electrical energy generated from the braking process can be dissipated through a resistive network (dynamic) or stored (regenerative), while the First Law of Thermodynamics dictates that the vehicle will slow down as this process unfolds.

As applied to rail vehicles and systems, regenerative braking offers two distinct benefits, the first being the consumption of this available electrical energy by the locomotive/train itself, while the second is the ability of the entire system to reuse the generated electricity.

Current State of Regenerative Braking Systems

The ability to return electricity is only available to trains that are electrically powered and in constant contact with their power sources, such as subways, light rail, and other catenary-driven systems. Diesel/electric locomotives that use regenerative braking can be considered “hybrid”, similar in concept and functionality to today’s hybrid automobiles, such as the Toyota Prius.

The ability to self-generate power by a rail vehicle allows for less dependence on traditional resources and in the case of the diesel locomotive, ultimately will reduce engine emissions, thereby meeting or exceeding air quality standards set forth by many governments.

Key global locomotive manufacturers such as GE, EMD, and Vossloh have embraced the notion of the hybrid diesel locomotive while Siemens, Alstom, Bombardier, Mitsubishi, and Kawasaki have committed to the electrical systems approach with their offerings. All of these manufacturers have commercialized vehicles and systems which are now finding their way onto the global stage.

Additional Electricity Generation Methods

Alternate electricity generation methods beyond regenerative braking include the use of flywheel technology as well as fluid compression techniques, although the two main methods of storage of the electricity captured via regenerative braking are battery packs and capacitor arrays.

The Supercapacitor Energy Storage System manufactured by American Maglev Technology is an embedded system that captures, stores, and discharges 0.7kWh of energy for use in commercial transit applications. This system consists of double-layer supercapacitors, along with the required conditioning choppers and auxiliary devices, necessary to capture and store a transit vehicle’s kinetic energy that would otherwise be lost during braking.

The Supercapacitor Energy Storage System manufactured by American Maglev Technology is an embedded system that captures, stores, and discharges 0.7kWh of energy for use in commercial transit applications. This system consists of double-layer supercapacitors, along with the required conditioning choppers and auxiliary devices, necessary to capture and store a transit vehicle’s kinetic energy that would otherwise be lost during braking.

Another variation of the capacitor concept widely accepted in the market is Maxwell Technologies‘ ultracapacitor. Maxwell ultracapacitors can absorb and store virtually all kinetic energy from a braking system. The stored emission-free electrical energy in ultracapacitors is then available to assist in vehicle acceleration, reduce fuel consumption and accompanying emissions, and power an air conditioner, lighting system, or other electrical vehicle function.

Another variation of the capacitor concept widely accepted in the market is Maxwell Technologies‘ ultracapacitor. Maxwell ultracapacitors can absorb and store virtually all kinetic energy from a braking system. The stored emission-free electrical energy in ultracapacitors is then available to assist in vehicle acceleration, reduce fuel consumption and accompanying emissions, and power an air conditioner, lighting system, or other electrical vehicle function.

Hybrid Rail Vehicles

Many of Japan’s railway operators are conducting field tests on new hybrid railway vehicles equipped with lithium-ion batteries. GS Yuasa is providing battery technology for these railway vehicles and expects wider adoption of the lithium-ion technology as mass-produced hybrid railway vehicles commence service. In addition, GE Transportation has also released a hybrid locomotive, the 4,400 horsepower Evolution Hybrid diesel-electric. It will feature a sodium/nickel battery system that will capture and store energy dissipated during dynamic braking.

Many of Japan’s railway operators are conducting field tests on new hybrid railway vehicles equipped with lithium-ion batteries. GS Yuasa is providing battery technology for these railway vehicles and expects wider adoption of the lithium-ion technology as mass-produced hybrid railway vehicles commence service. In addition, GE Transportation has also released a hybrid locomotive, the 4,400 horsepower Evolution Hybrid diesel-electric. It will feature a sodium/nickel battery system that will capture and store energy dissipated during dynamic braking.

Currently, there are multiple technologies in play for the capture, storage, and application of braking energy once immediately disposed of as heat, with no clearly dominant technology that will satisfy all regenerative braking applications. In addition, currently there are no standards regarding connector interfaces supporting the segment. One must assume that as demand increases for the various technologies, approaching an economy of scale, the need for specific interconnect devices might establish a de facto standard among the myriad of off-the-shelf products.

- Satellites and 3D Radar Will Drive the Aviation Evolution - October 6, 2014

- Regenerative Braking Systems in Rail Applications - February 13, 2014

- Reinventing Your Wheels: Auto Convergence Technology - November 18, 2013