Commercial Connectors Toughen Up for the Harshest Environments in the Universe

As priorities for deep-space applications change, demand is increasing for low-cost, commercial off-the-shelf connectors that can endure the rigors of space.

Deep-space exploration keeps bringing us new information about the sun, the moon, and the planets. For example, data from NASA’s Lunar Reconnaissance Orbiter recently helped researchers determine that the Moon isn’t dead because it shows signs of recent tectonic activity. The Hubble Space Station celebrates its 30th anniversary in 2020. Over the decades, the Hubble Space Telescope has taken over a million observations and provided data that astronomers have used to expand our fundamental understanding of the cosmos.

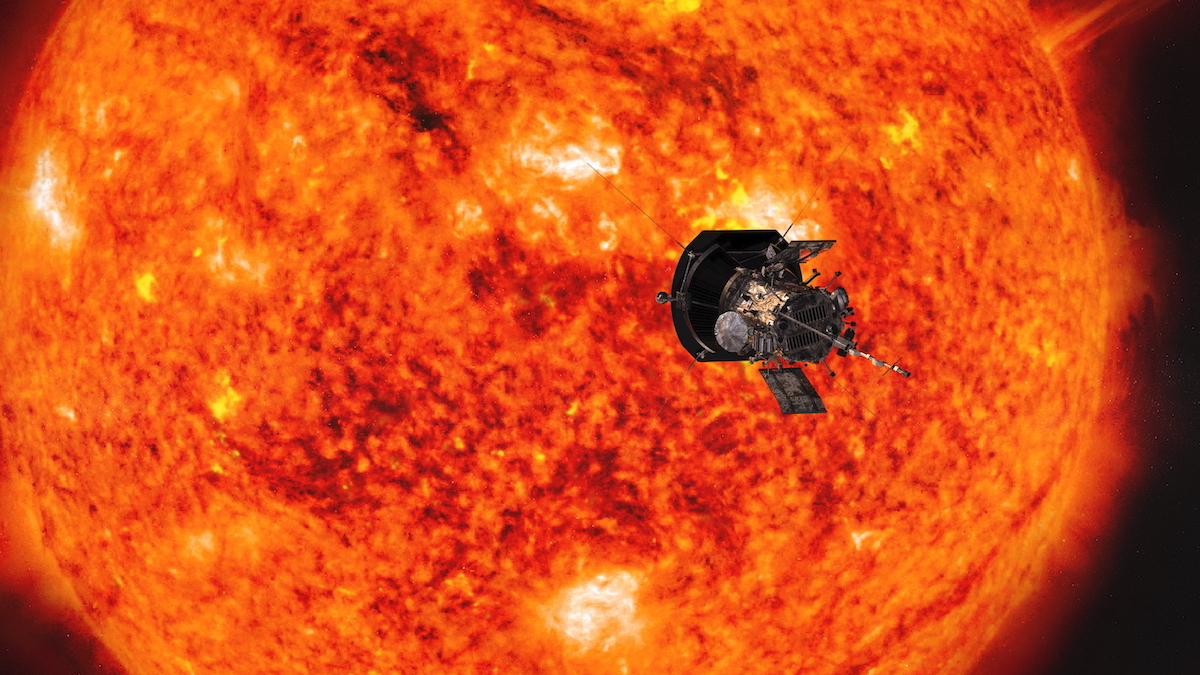

In this artists’ concept, NASA’s Parker Solar Probe spacecraft approaches the Sun to study its corona and the solar wind. (Source: NASA)

But a major shift is happening in space systems. Funding is increasingly shifting from scientific exploration to commercial missions closer to Earth, such as geosynchronous orbit (GSO) communications satellites. A growing number of small, low-Earth-orbit (LEO) satellites are crowding the skies as space becomes even more commercialized. Products and services for commercial space applications total just over half of the $415 billion space market, according to the 2020 annual report from the US-based Space Foundation.

Connectors are a critical part of deep-space applications. TE Connectivity’s products for deep space are typically used in one-off applications that are mostly NASA-specific, said Russ Graves, global aerospace business development manager. Requests for those products are becoming fewer and farther between than requests for connectors destined for LEO applications, he said. “A decade ago, the main line of our satellite business was GSO,” said Graves. “Now the main part of our satellite business, and of the industry, is LEO.”

TE Connectivity’s RF connector products include standard, subminiature, and microminiature interfaces and frequencies, as well as flexible and semi-rigid cable.

In recent years, the trend toward near-Earth-orbit (NEO) and LEO satellites has been accelerating with regard to both the types of applications and types of companies requesting connectors for this market. Demand is coming from around the world as deep-space activities continue to expand.

A Shift to Commercial Applications

“Our space-flight technology heritage is founded on either scientific exploration or on defense advancement, and all major space-bound missions have been traditionally financed by ‘unlimited’ government budgets,” said Gaby Cristian Mindreci, director of sales for Europe for Positronic. This fostered “ultra-high levels of performance criteria for harsh environments, long system lifetimes, and very tight component tolerances.” For example, up to 10 different possible models could be required for highly complex qualification testing, all for a single flight model.

Since the internet’s advent, the industry is shifting toward commercialized communication services, such as mega-satellite “constellations.” Demand for commercial-level, high-performance components has increased exponentially since the first such constellation was launched in 2014. “Components that traditionally cost hundreds of dollars are now expected to be available in commercial off-the-shelf [COTS] versions compatible with space flight that cost in the range of tens of dollars. Connector suppliers must find a way to keep the high performance levels while cutting costs significantly,” Mindreci said.

Due to these changes, many companies are focusing primarily on commercial space applications such as LEO, and less on deep-space missions. Radiall had developed its SMP-LOCK space connector to provide a low-cost, high-performance connector with a quick-lock interface to simplify installation. The SMP interface has been widely used in phased radar arrays because it enables designers to increase the density of RF channels with a lightweight solution that helps reduce payload. It has been specified for projects like the Iridium Satellite constellation program.

Radiall’s SMP-LOCK microminiature connectors are fully compatible with SMP interfaces and feature a secure locking mechanism for a secure connection.

“The customer base is shifting from large OEMs funded by government to small companies, even startups,” said Giorgio Potenza, head of product and market development for Harwin. Instead of space-grade components, NEO/LEO customers want available connectors that can do the job. Major improvements in COTS connectors that were initially developed for use in deep-space missions have made many models usable in low-orbit applications.

Requirements for LEO and Deep-Space Connectors

When it comes to components for space systems, most of TE Connectivity’s LEO products are also applicable for deep space systems. “It depends on the direction we get from the customer,” said Graves.

The main difference is concern about plastics outgassing in a vacuum, as this causes molecular-level changes that affect other components, wiring, and plastics in interconnects and other components. General industry standards for LEO outgassing are based on lower radiation levels than are found in deep space, said Graves. Because of their revolution speed in operation, LEO satellites also experience more and faster temperature cycling than GSO and deep-space applications.

Although most of TE Connectivity’s products for small LEO satellites are also applicable to deep space, its CeeLok FAS-T Nano connectors are made specifically for the LEO market.

For deep-space applications, the most important connector requirement is reliability. “So, customers want to use preferred products as a starting point,” said Graves. Depending on the mission, those products must be tested to particular extremes, usually involving temperature characteristics. The next stage of testing involves radiation hardness. “Those concerns are usually associated with the plastic, not metal, components of connectors,” said Graves. “For metal parts, testing is mostly about thermal expansion and contraction.” But connectors contain so many different plastics that both individual materials and how they interact must be examined. Connectors are also evaluated based on size and weight, to help conserve fuel or energy, said Graves.

Data rates are also a concern for deep-space applications, and designers often select products for their ability to handle high-speed data transmission over copper or fiber. Although fiber optic cable benefits most deep-space applications, different variants of glass fiber for different rad-hard abilities are available and must be closely examined for suitability. Other major requirements are power levels and radio frequency (RF) capabilities.

Radiation is a big concern for a satellite’s major signals and impacts connector selection. In near-orbit and low-orbit applications, these are mostly low-speed signals. Shielding can be used, but it adds weight and cost. Other major concerns are thermal cycling and shock and size, weight, and power (SWaP). “Engineers are pushing the whole performance of the system. They’re trying to save weight, cram signals into a small area, and make sure cost is contained,” said Potenza. “So they need to consider lots of tradeoffs. But even with connectors, the radiation problem can normally be designed around.”

Connectors Designed for LEO

Some low-Earth-orbit satellites are even smaller than compact CubeSats; 6U, 3U, and even some 1U sizes are increasing in use. These newer, smaller satellite designs not only have to withstand the toughest environments, but also satisfy demands for even more miniaturized, high-density parts.

Compared to satellites for deep space, near-orbit satellites are also subject to a lot more standardization. “Our customers want to know what works specifically for these satellites, not just what worked previously for deep-space satellites,” said Potenza, who says engineers are moving away from Micro-D type connectors to more lightweight, compact alternatives.

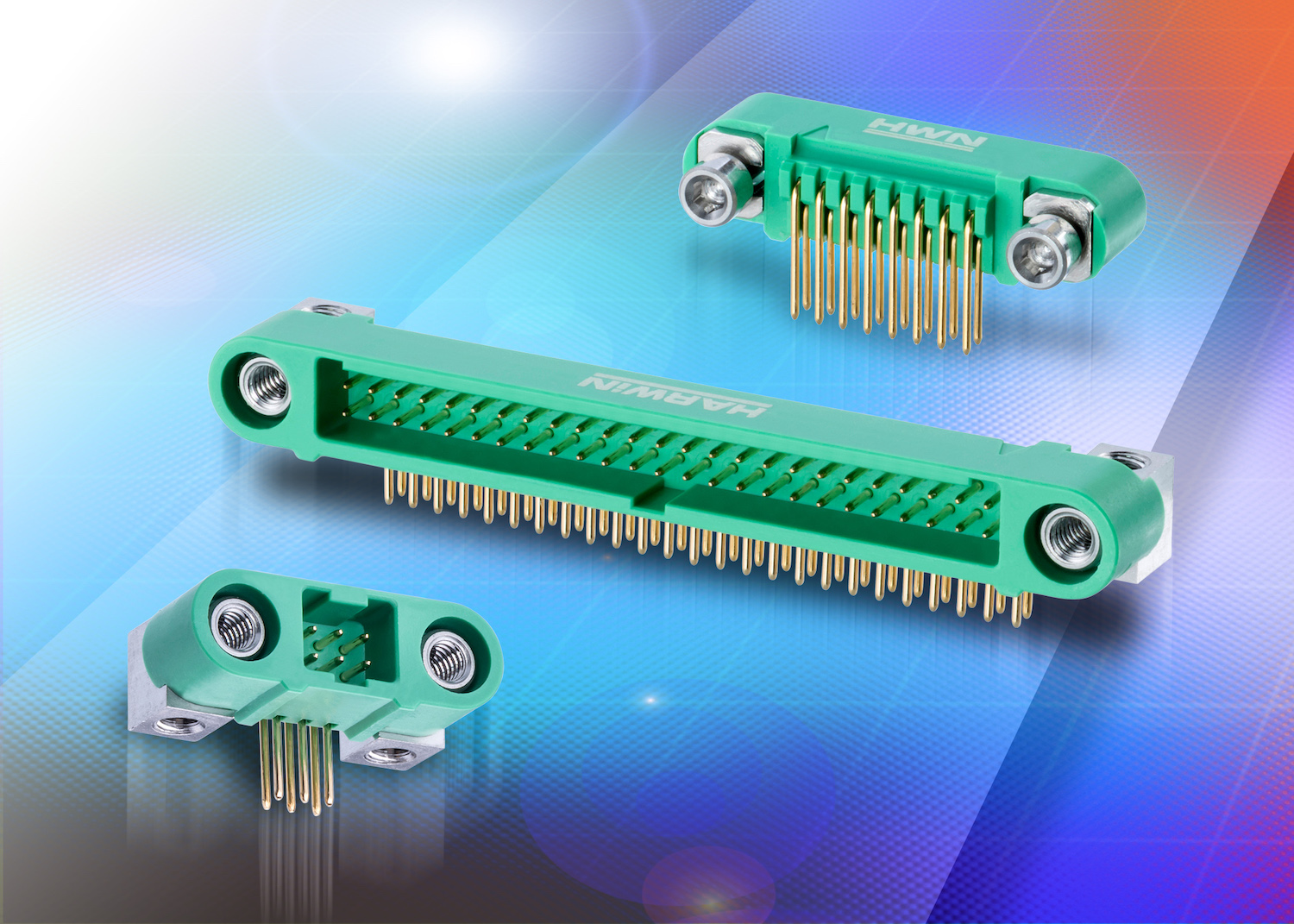

Harwin has added right-angle termination options to its Gecko-SL (Screw-Lok) 1.25mm pitch connectors. The new horizontal male connectors offer additional layout flexibility for small satellite applications, enabling substantial space savings for cable-to-board applications.

Positronic specializes in developing high-performance, high-reliability products that can meet very specific requirements, said Mindreci. Its connectors use high-performance materials and have the highest power density on the market.

The solder integrity of connectors soldered on PCBs requires very complex inspection to minimize malfunctions, said Mindreci. So, in early 2016, the company began pre-qualification testing for its low-force-compliant press-fit technology, which has major manufacturability advantages. The results were shared at the European Space Agency (ESA) during its 2016 Space Passive Component Days symposium.

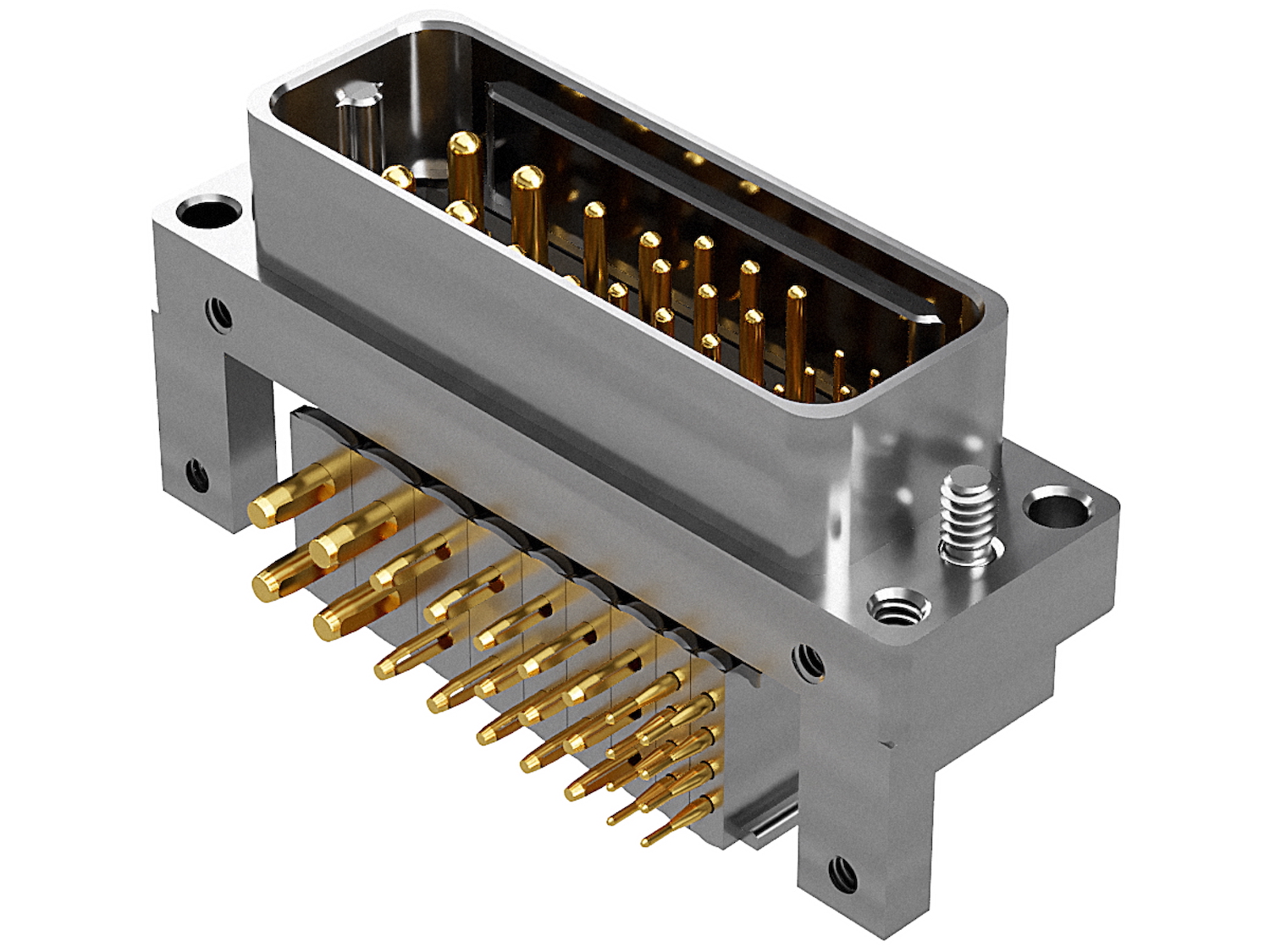

“We proved that these products can replace solder alternatives for a lower installed cost and also allow for volume manufacturing,” said Mindreci. By the end of 2020, Positronic plans to have two connector series qualified to ESA specifications: Press fit D-Sub connectors and the ScorpionMAX Series.

The Scorpion SPMAX hybrid power and signal connector from Positronic is currently under qualification to European Space Agency (ESA) specifications.

“Competition in the space business has gotten fierce,” said Mindreci. “Everybody is starting the race for price now. Being a leader in this market is not only about being a leader in technology, but it’s also about having competitive pricing and availability. If I have a connector that will do the job, but it has very long lead times, I may fail to get it designed in. The industry is slowly opening to adopting high-performance commercial-type products, but it will probably take a few more years to see the trend go in that direction.”

Like this article? Check out our other Connection Basics, Harsh Environment, and High Reliability articles, our Military/Aerospace Market Page, and our 2020 and 2019 Article Archives.

- Underwater Connectors Get Smaller and Tougher for Submarines and UUVs - November 10, 2020

- Small Military UAVs Demand Smaller, Lighter Connectors - August 4, 2020

- Commercial Connectors Toughen Up for the Harshest Environments in the Universe - June 2, 2020