Connectivity is the Future of Automotive Design

In 2020, the world is adjusting to new automotive use patterns and considering competing fueling strategies. Only one thing is certain: Cars are becoming more connected.

The future of automotive design centers on the continued development of electric vehicles and the integration of connected technologies within non-electric vehicles. While the adoption of electric vehicles is still in its early stages, connected technologies are already dominating new vehicle models across all fueling modes. Innovations in safety, infotainment, onboard diagnostics, and fuel efficiency depend on connected systems, bringing sensors, cameras, and antennas into the forefront of vehicle design. As we move closer to 5G implementation, interfaces between individual vehicles and transportation infrastructure will become critical systems in passenger vehicles. Thousands of electronic components will support these new functionalities.

A Greener Future

Despite a pause for the COVID-19 pandemic, the global automotive market is expected to expand over the next five years and electric vehicles will account for a growing part of that expansion. In 2019, electric vehicle sales accounted for less than 3% of global new car sales. However, in Q12020, when most OEMs were missing sales projections, Tesla’s Model 3 set records for sales and deliveries, beating expectations with sales of 88,400 vehicles. In April 2020, when most auto dealerships closed, Tesla continued to deliver vehicles to buyers through its dealer-free ordering process. In the UK, auto sales declined by more than 97%, but electric vehicle sales declined by only 10%. In France, electric auto sales made up 7.8% of all new car sales in April 2020. TTI estimates that within 10–15 years, more than half of all new auto sales will be electric.

Connectors that can support high voltages are helping to advance electric and hybrid electric technologies. Linyi New Energy Technology Co. designs high-voltage, high-current connectors and wiring harnesses for electric vehicles. Its PRC500A connector has a rated current of 500A at 1,000VDC, is sealed to IP68, and features patented thermistor integration ideal for use in battery management systems (BMS) power distribution units (PDUs), e-drives, and e-motors. The company also designs and produces a patented DC fast-charging socket with replaceable contact terminals. “This product makes it easier to maintain and repair charging stations in the field,” said a Linyi representative. “Charging infrastructure is in high demand to support EV adoption, and we consider it just as important to provide quality components for the charging networks as for the vehicles that will use them.”

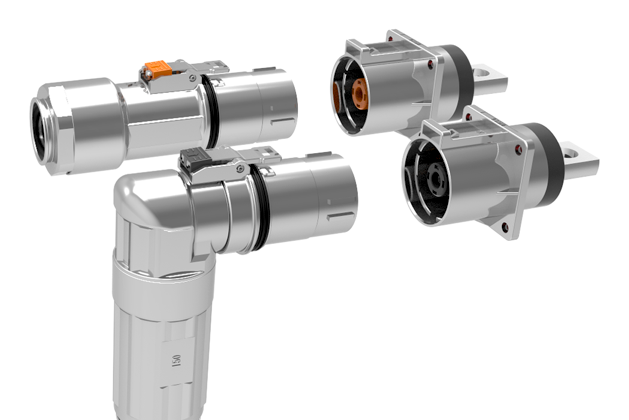

Linyi’s PRC500A high-voltage connector is fully shielded and waterproofed for rugged automotive designs.

Connected Inside and Out

Spring of 2020 brought a hitch to the EV market in the form of record low oil prices. If they persist, low prices at the pump are likely to delay widespread adoption of the electric car, as saving money on fuel is one of the primary incentives for electrification. However, other electronic technologies have infiltrated vehicles outside of the EV market. Sensors are now a significant part of automotive systems, monitoring everything from predictive vehicle maintenance to road conditions.

Fischer LP360 connectors offer 360-degree mating, plug-and-use connectivity, and compatibility with USB 2.0 and Ethernet data protocols.

Fischer Connectors’ LP360 product line includes a compact and low-profile panel plug that can be directly integrated into the housing of fixed sensors in automotive and other applications where SWaP (size, weight, and power) is critical. These connectors are ultra-rugged, EMI-shielded, and resistant to shock, vibration, torque, and extreme temperatures. Their IP67- or IP68-rated membrane-sealed contacts allow for easy cleaning as well as protection from dust and sand and their blind-mate, quick-release locking mechanism is non-magnetic, which means no debris is attracted to the connector and there’s no interference with sensors.

Power and Signal Group provides connectivity solutions for a wide variety of automotive applications. In addition to connectors, the company offers sensors by Merit Automotive Electronics Systems, including oil, coolant, and transmission temperature sensors for onboard diagnostics and predictive maintenance. These sensors operate in harsh environmental conditions to collect data about operating conditions, fluid levels, performance, and other factors, transmit that data to an electronic control unit where diagnostics are performed, and transmit pertinent data to the driver via dashboard messaging.

Connectivity within the vehicle, connectivity between individual cars, and Smart City infrastructure will increase as 5G arrives in more cities. Cars equipped with vehicle-to-vehicle (V2V) communications systems share safety, mobility, and traffic information over wireless networks. These systems require high-speed connectors and cables that can transmit image and video data. Hybrid connectors that can handle both data and power are becoming standard vehicle components. In addition to ruggedization, the connectors and cables in these systems must be insulated to protect against EMI and crosstalk.

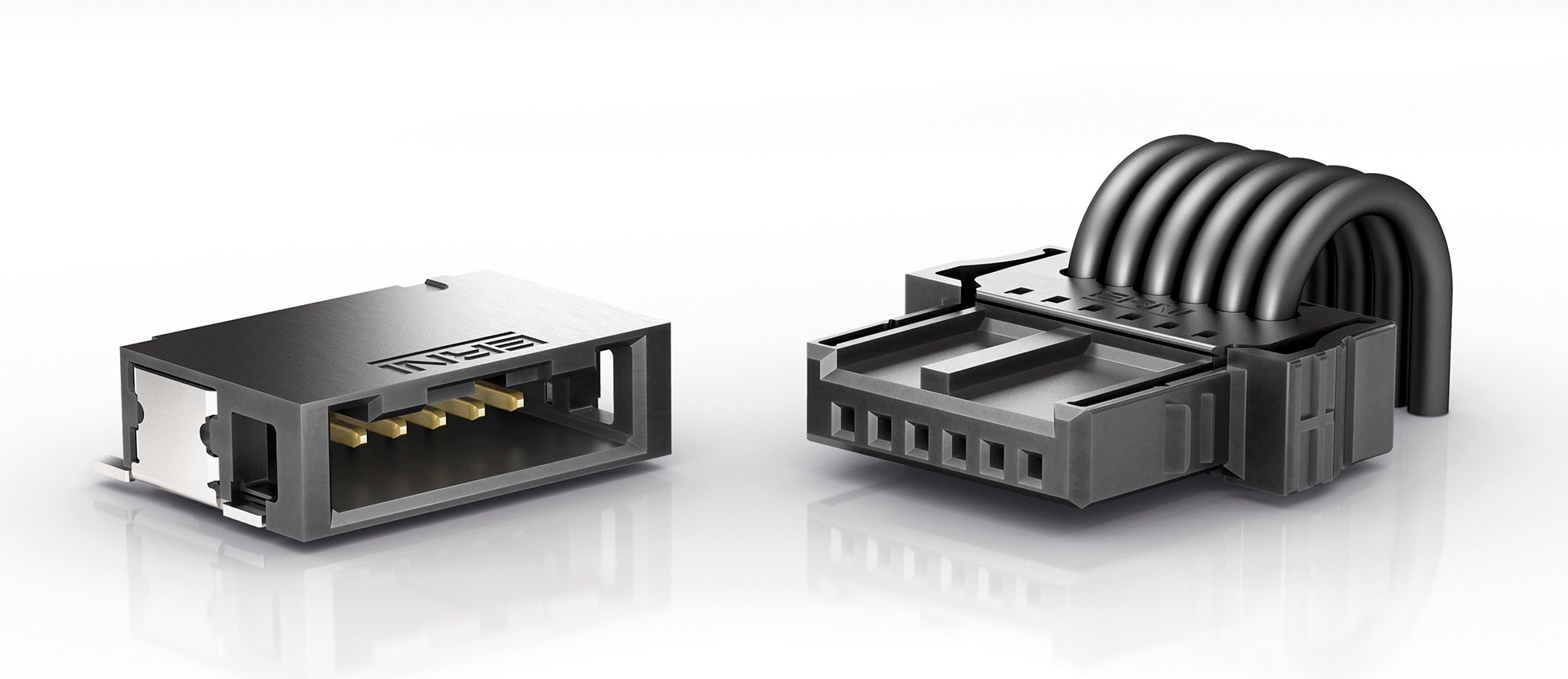

ERNI’s MicroBridge connectors resist temperature extremes up to 150°C, which makes them well suited for harsh-environment automotive designs.

ERNI’s MicroBridge cable-to-board connectors for automotive applications are designed to provide high-speed connectivity in harsh automotive environments. These connectors meet the demanding automotive test specifications VW75174 and USCAR-2 and offer high mating integrity and reliable processing. They have also been designed to provide Koshiri security against damage caused by improper or skewed insertion.

Molex’s HSAutolink Interconnection System brings high-speed components into the automotive environment.

The HSAutoLink Interconnect System from Molex accommodates Ethernet and low-voltage differential signaling (LVDS) and protects against interference in automotive designs that increasingly include multiple connected systems.

Car use and buying habits will no doubt be altered by the events of 2020, but it is certain that connectivity will be one factor that continues to grow in new automotive design.

Like this article? Check out our other New Technology, Connected Vehicles, and high reliability articles, our Automotive Market Page, and our 2020 and 2019 Article Archives.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024