Connectors for Military Applications Speed Navy Communications

Updating shipboard communication systems with fiber optics and high-speed technologies requires a bevy of high-performance, specialized connectors for military applications.

Advanced communications technologies are a critical focus for naval system developers. As new equipment takes to the seas, connector makers are being asked to provide high-speed components that are simple and easy to use and meet the unique specifications required for military environments.

The global push to modernize ships and simplify communications throughout fleets is creating a huge need for electronics that can perform in marine applications, as well as interface with aircraft, drones, military personnel, and land vehicles. Specialized connectors for military applications are at the heart of the infrastructure for these new systems.

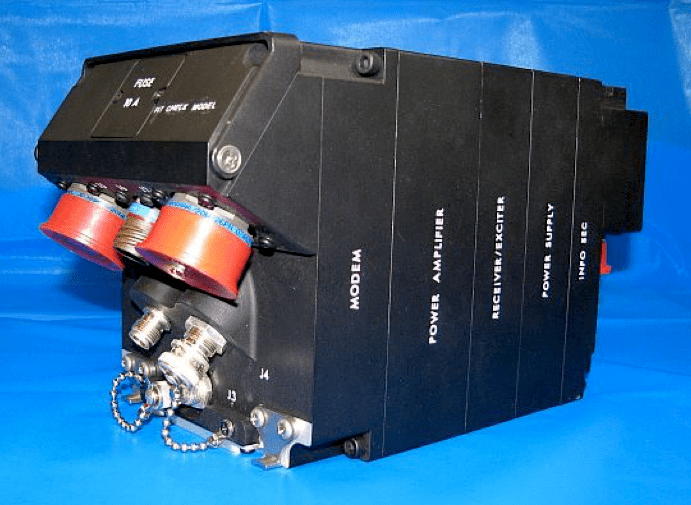

Rockwell Collins recently landed multi-million-dollar orders for AN/ARC-210 avionics radios and related equipment for US and foreign military aircraft. The Naval Air Warfare Center Aircraft Division awarded $370 million in contracts to Rockwell Collins for the US Navy, Air Force, Marine Corps, and allied military forces.

Ethernet connectors are a mainstay of Rockwell Collins radios.

A critical element of AN/ARC-210 is a connector for Ethernet input, which has become more important as the military moves towards network-centric warfare. The AN/ARC-210 radio operates over frequencies from 30 to 512 MHz, covering UHF and VHF bands with AM, FM, and satellite communications while providing embedded anti-jam waveforms and secure communications. The radios communicate over a MIL-STD-1553 data bus.

On another front, Boeing is working on high-speed fiber-optic shipboard networks for US Navy Arleigh Burke-class guided missile destroyers. A $15.9 million order was handed out earlier this year. The Naval Sea Systems Command tasked Boeing Defense, Space & Security with supporting shipboard AN/USQ-82(V) networking systems.

These systems include the Data Multiplex System, the Fiber Optic Data Multiplex System, and Gigabit Ethernet Data Multiplex System. They handle inputs and outputs for the destroyer’s machinery control systems, damage control system, steering control system, Aegis combat system, navigation displays, and interior communications alarms and indicators. The new shipboard network equipment replaces miles of point-to-point cabling, signal converters, junction boxes, and switchboards.

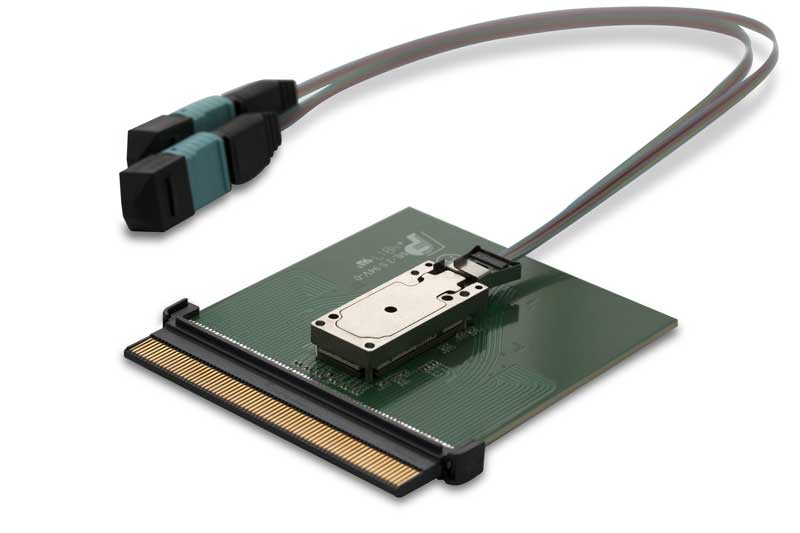

The LightABLE™ LL 150G full duplex devices are designed to be embedded on printed-circuit boards in close proximity to high-speed electronics in high performance embedded computing systems. (Source: Reflex Photonics)

Specialized Connectors for Military Applications

Specialty connectors are helping naval design teams make the transition to optical links. Reflex Photonics Inc. just unveiled compact LightABLE LL 150G full-duplex (12+12) 12.5Gb/s per lane optical fiber transceivers for harsh environments. The blind matable parts, based on VITA’s OpenVPX standards, weigh less than 5g, and have power consumption as low as 120mW per lane.

European militaries are also investing in communications systems. In October 2018, the French Navy announced that more than 60 of its vessels are now equipped with RIFAN 2 systems, which provide secure intranet communications.

Fiber optics is seeing more use as bandwidth demands rise. (Source: Reflex Photonics)

Providing Support to the Military

Design teams have numerous products to choose from that can help them improve communications and simplify installation and maintenance of cabling and connector systems. Many connector manufacturers are also working closely with military customers to speed up their efforts to digitize design processes to include simulation and validation.

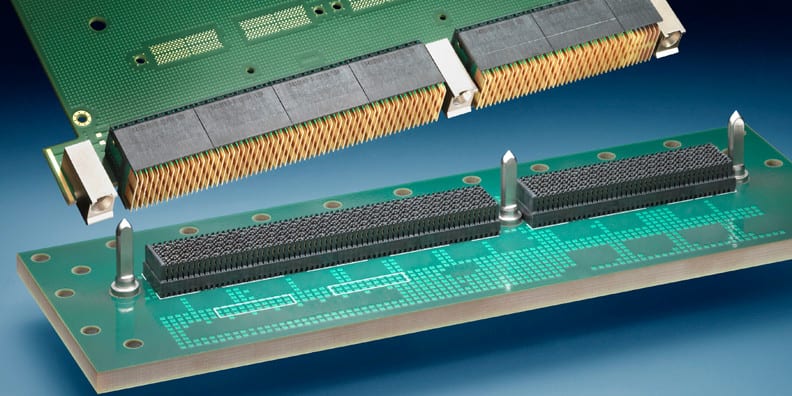

TE recently upgraded its MULTIGIG line.

TE Connectivity and SnapEDA, a Web-based parts library for circuit board design, have partnered to make more than 25,000 digital models available to electronics designers. Board designers often had to spend days creating component models; now with this resource, they can save plenty of time by using commercial off-the-shelf (COTS) files. Connectors are particularly difficult to model because they have non-standard shapes, pitches, pads, and cutouts. Access to free printed circuit board footprint and symbols for TE components can save engineers days of effort, freeing up time for product optimization and innovation.

While much of the industry’s development work is targeted at new designs, there’s also high demand for processes and products that make it easier to update and maintain naval equipment, which often sees several years or even decades of service. The US Navy is asking the electronics industry to help develop new repair concepts for cable shield ground adapter (CSGA) cabling and connector technology for use aboard surface warships. The Naval Surface Warfare Center Dahlgren Division is seeking research and development partners that can provide a reliable CSGA for cable and connector repair.

Equipment makers and connector makers alike are pushing more towards COTS technologies. These efforts are being addressed by Molex, which is developing high-density VITA 67 Backplane Solutions. Its 4- and 8-port configurations incorporate 26.5 GHz SMPM interfaces needed by high performance Versatile Performance Switching (VPX) platforms.

Molex provides a range of connectors for VITA-compliant systems.

Given the navy’s long product lifecycles, backwards compatibility is a central factor for new products. TE’s MULTIGIG RT 2 connector has been “up-ruggedized” to meet stringent VITA 72 testing requirements for ruggedness and reliability while maintaining compatibility with the original rugged MULTIGIG components. The MULTIGIG RT 2-R connector’s contacts were redesigned so each beam has two points of contact to roughly double the contact patch area with the wafer. The new contact system can also reduce mating forces by up to 10% without sacrificing durability.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024