Glass Connectors for Nuclear Applications

In an effort to safeguard the electronics within nuclear power plants, connector companies have turned to an age-old material.

Nuclear power is an important source of high-density, long-lasting, and low-emissions energy. A critical part of a diverse global energy mix, nuclear power plants provide 10% of the world’s energy, with some countries, like the US at 20% and France at 75%, drawing even higher amounts of power from this source. Countries like China and Russia are bringing new plants online, including a new floating nuclear power plant design. Russia will deploy seven of these ocean-site stations, with the first activating in 2019, and China will launch 20 more of its own.

Nuclear power is an important source of high-density, long-lasting, and low-emissions energy. A critical part of a diverse global energy mix, nuclear power plants provide 10% of the world’s energy, with some countries, like the US at 20% and France at 75%, drawing even higher amounts of power from this source. Countries like China and Russia are bringing new plants online, including a new floating nuclear power plant design. Russia will deploy seven of these ocean-site stations, with the first activating in 2019, and China will launch 20 more of its own.

Safety is a critical part of these installations. The 2011 Fukushima Daiichi disaster in Japan has spurred intense emphasis on safety, and the electronic components used in plant systems and design can play a critical role in helping to secure these plants. A recent report by the International Atomic Energy Agency (IAEA) highlights the potentially severe issues that can occur as a result of electrical instrumentation and control equipment failure under severe accident conditions and offers recommendations for electrical and I&C equipment for use within nuclear power plants. The report underscores the importance of components that are able to withstand severe accidents, such as a core melt.

Thomas Fink, general manager of SCHOTT’s nuclear safety division, is an authority in glass-to-metal sealing technology, especially with respect to its use in nuclear applications. Since Fukushima, he’s written extensively about nuclear safety and what the electronic industry has learned from the accident. We talked to him about how electronics can play a role in safer nuclear plants.

What electronics products are helping to make nuclear power safer?

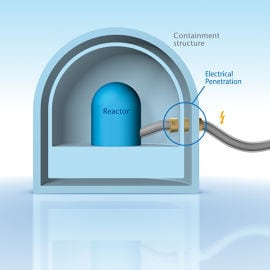

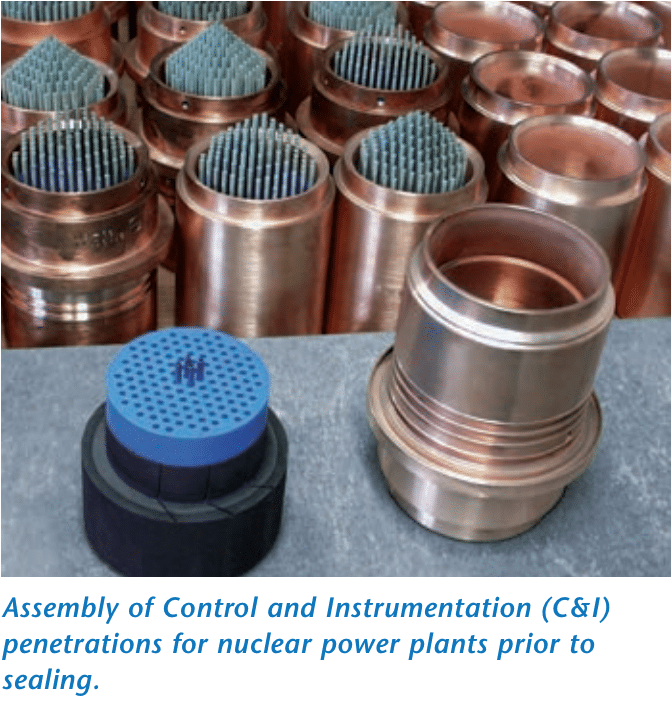

Thomas Fink: Glass-to-metal sealed electrical penetration assemblies (EPAs) are feedthrough components that help enable the safe and reliable transmission of electricity and data signals through the gas-tight containment walls of nuclear reactors. As such, the most important functionality aspects of the EPAs are two-fold: providing a permanent pass-through mechanism for reactor cabling and maintaining the pressure boundary of the sealed-off reactor containment wall. With these functions, EPAs play a key role in safety at nuclear power plants. Maintaining electrical and data transmission infrastructure and the containment pressure boundary is necessary for smooth day-to-day operations and critically important in the event of a severe accident. EPAs must be able to withstand high temperatures and extreme pressures that develop should a severe accident occur to help mitigate the effects by playing a role in preventing loss of reactor control and minimizing radiation leakage.

Thomas Fink: Glass-to-metal sealed electrical penetration assemblies (EPAs) are feedthrough components that help enable the safe and reliable transmission of electricity and data signals through the gas-tight containment walls of nuclear reactors. As such, the most important functionality aspects of the EPAs are two-fold: providing a permanent pass-through mechanism for reactor cabling and maintaining the pressure boundary of the sealed-off reactor containment wall. With these functions, EPAs play a key role in safety at nuclear power plants. Maintaining electrical and data transmission infrastructure and the containment pressure boundary is necessary for smooth day-to-day operations and critically important in the event of a severe accident. EPAs must be able to withstand high temperatures and extreme pressures that develop should a severe accident occur to help mitigate the effects by playing a role in preventing loss of reactor control and minimizing radiation leakage.

[In addition to SCHOTT, glass-to-metal sealed EPAs are available from companies including Teledyne Brown Engineering, Vac-Tron (Barcelona), and Mirion Technologies]

How do these products differ, in terms of materials or design, from other harsh environment connectors?

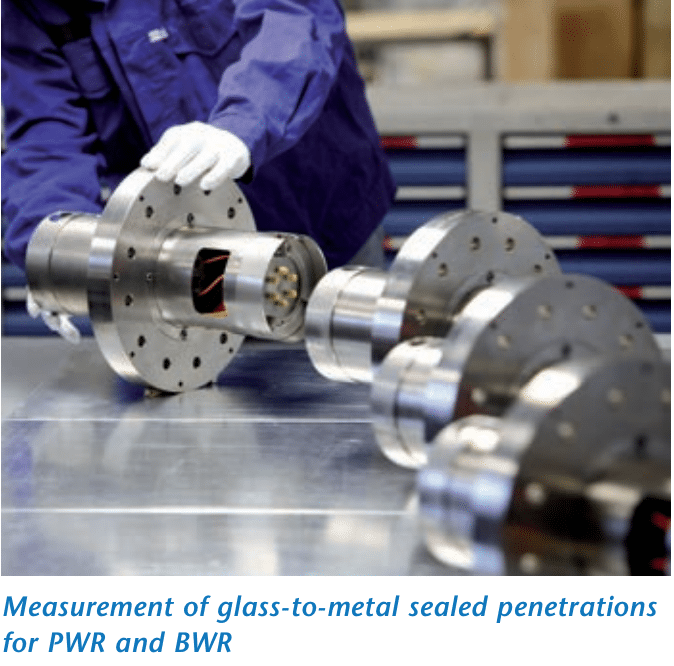

While many harsh environment connectors utilize organic sealing materials such as epoxy or PEEK polymers, SCHOTT utilizes inorganic and non-aging glass-to-metal sealing materials to create a hermetic boundary in their harsh environment connectors. Organic polymer materials naturally age and degrade over time and can potentially be compromised in a high-pressure high-temperature environment. Glass-to-metal seals, on the other hand, have been tested to withstand 752°F temperatures and pressure levels of 5,200PSI and higher for extended periods of several hours, similar conditions to those measured in previous severe accidents at nuclear power plants. Maintaining integrity of the electrical penetration assembly increases the likelihood of maintaining reactor control even under extreme conditions, potentially mitigating adverse effects and possible radiation leakage. These robust safety-relevant properties have made glass-to-metal sealed EPAs the preferred choice—and in some cases even the standard—in modern nuclear applications.

While many harsh environment connectors utilize organic sealing materials such as epoxy or PEEK polymers, SCHOTT utilizes inorganic and non-aging glass-to-metal sealing materials to create a hermetic boundary in their harsh environment connectors. Organic polymer materials naturally age and degrade over time and can potentially be compromised in a high-pressure high-temperature environment. Glass-to-metal seals, on the other hand, have been tested to withstand 752°F temperatures and pressure levels of 5,200PSI and higher for extended periods of several hours, similar conditions to those measured in previous severe accidents at nuclear power plants. Maintaining integrity of the electrical penetration assembly increases the likelihood of maintaining reactor control even under extreme conditions, potentially mitigating adverse effects and possible radiation leakage. These robust safety-relevant properties have made glass-to-metal sealed EPAs the preferred choice—and in some cases even the standard—in modern nuclear applications.

What types of applications are glass-to-metal sealed EPAs used in?

SCHOTT EPAs have uses in a variety of applications in the nuclear sector. The most notable application is civil nuclear power plants, in which SCHOTT EPAs are present in more than 50 power stations across the globe as a hermetic feedthrough assembly for through-wall cabling into the reactor structure. We have also recently been working with plant construction companies to integrate glass-to-metal sealed EPAs into next-gen nuclear reactors: most notably small modular reactors (SMRs) and high-temperature reactors (HTRs). The elevated temperatures and pressures of these reactor-type environments make glass-to-metal EPAs the only viable feedthrough solution, as polymer counterparts are unable to function without issue in such conditions. Glass-to-metal sealed EPAs can also be found in nuclear-powered vessels, including submarine applications. They can also be used in retrofitting projects for existing nuclear power plants. These types of efforts can help extend the viability and lifespan of existing reactors for anywhere from a few years to several decades of continued operation.

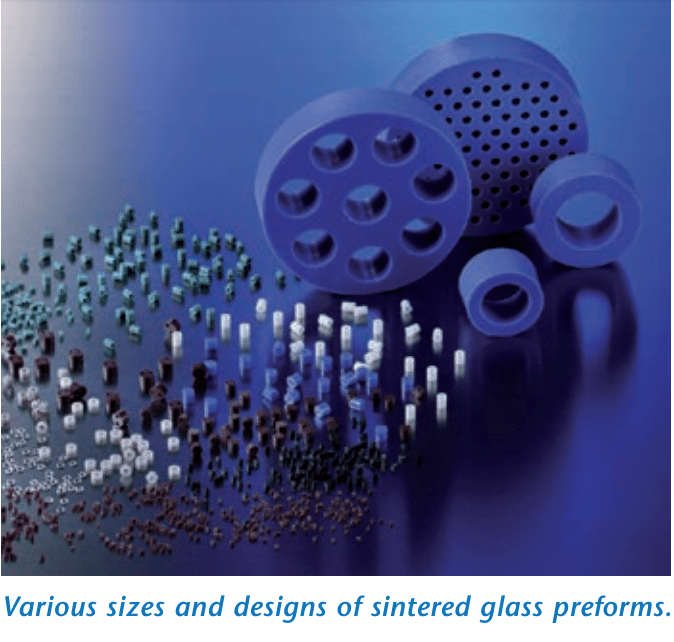

How does this area of specialty fit into SCHOTT’s overall expertise?

SCHOTT is an innovator and world leader when it comes to all things glass. Glass-to-metal sealed electrical penetration assemblies for nuclear applications are a unique offering in which SCHOTT has utilized glass as a sealing material. In their usage, glass-to-metal seals offer exceptional robustness and seal integrity uncompromised by severe surrounding conditions such as high temperature and pressure. While it offers distinct advantages for the nuclear sector, glass-to-metal seals are not limited to the field: supported applications and industries for glass-to-metal connectors and feedthroughs include automotive electronics, consumer electronics, aviation and aerospace, energy storage, datacom, and medical electronics and devices.

SCHOTT is an innovator and world leader when it comes to all things glass. Glass-to-metal sealed electrical penetration assemblies for nuclear applications are a unique offering in which SCHOTT has utilized glass as a sealing material. In their usage, glass-to-metal seals offer exceptional robustness and seal integrity uncompromised by severe surrounding conditions such as high temperature and pressure. While it offers distinct advantages for the nuclear sector, glass-to-metal seals are not limited to the field: supported applications and industries for glass-to-metal connectors and feedthroughs include automotive electronics, consumer electronics, aviation and aerospace, energy storage, datacom, and medical electronics and devices.

Can you tell us about some specific projects they have been used in?

SCHOTT recently announced a partnership with Chinergy Co., Ltd. and Jiamusi Electric Machine Co., Ltd. to help support the construction of the Shidaowan twin-reactor high-temperature reactor (HTR) by supplying Eternaloc® electrical penetration assemblies. Our glass-to-metal sealed EPAs are being utilized in the primary loop of the HTR due to their ability to withstand the high temperatures and pressures of the environment. The Shidaowan twin-reactor HTR facility is also a small modular reactor (SMR), which differ from regular small reactors in the way that they need their components manufactured in-plant for fast replacement and long-term cost efficiency – something SCHOTT is able to support with its long-term manufacturing process expertise.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024