High-Tech Energy Systems Bring Agriculture Indoors

LED lighting, along with innovative cooling and irrigation systems, are inspiring the greatest agricultural transformation since the advent of the tractor.

Chances are good that the tomato on your salad or the basil on your pizza didn’t grow outside under the sun. Instead, it may have come from an indoor growing facility, nurtured by the warm glow of technology. Indoor agriculture is rapidly expanding, and food crops such as leafy greens, mushrooms, tomatoes, strawberries, and herbs — in addition to the biggest cash crop of them all, cannabis — are thriving in high-tech indoor farms that depend on electronics. This young industry is about to exponentially expand, which translates into tremendous opportunities for electronics manufacturers.

Image Credit: NASA Marshall Space Flight Center

As the global food industry prepares for a human population of 10 billion by the year 2050, the race is on to find ways to feed us all. Indoor agriculture, with its high yields, lower pest control issues, compressed land use, and continuously ideal growing conditions, will be a critical part of the solution. A global estimate of $300 billion worth of food is grown indoors, and that number is poised to skyrocket, and soon. In 2016, US indoor food operations produced crops with a market value of $14.8 billion, and that’s not counting the cannabis market, which brought in another $6.7 billion in legal sales.

In February, Bowery Farm, a vertical farming startup, raised more than $20 million to expand its operations. In June, AeroFarms received a $34 million investment to bring indoor farming to the Middle East. In July, the indoor farming startup Plenty received $200 million in backing from billionaires including Jeff Bezos and Masayoshi Son. The company’s global rollout of vertical indoor farms purports to produce crops at yield 530 times greater than that of a typical field.

Vertical farming can maximize compact growing spaces. (Top Photo Credit: Bright Agrotech; Bottom Photo Credit: Michael Trolove)

So, What’s the Tech?

Indoor farming, also known as controlled environment agriculture (CEA), depends on a complex network of technology, including sensors, energy and lighting systems, monitoring equipment, climate control technology, and hydroponics equipment. While traditional greenhouse agriculture utilizes some natural light, today’s CEA operations fit into enclosed existing infrastructure, such as empty warehouse space or even shipping containers, making it a viable urban renewal strategy in areas with overbuilt retail spaces, vacated sporting complexes, or former manufacturing facilities.

The energy needed to operate a CEA facility is considerable, but the recent drop in price of LED lightning has removed a tremendous roadblock to growth. Affordable, year-around sunshine is now available via LED light bars. These long, compact strips of light are usually equipped with heat sinks to draw the heat generated by the lights away from the plants. Another option is LED fixtures that include fan systems for active cooling.

“We are definitely seeing more interest in components that can be used in agricultural lighting systems,” said Tom Anderson, product manager at AVX, a manufacturer and supplier of passive electronic components and interconnects.

“We add several new components and connectors every year that are developed for indoor agriculture. This isn’t a spin-off industry — these are entirely new technologies, because it is so dependent on LED lighting, which is changing so rapidly. Agricultural applications have specialty needs. The connectors need to be white instead of black and typically low profile, for instance, to eliminate shadowing and visible black spots in the array. These systems are so carefully calibrated to create perfect growing conditions that everything, from color to factors like thermal management, comes into play.”

Companies like Philips, GE, Panasonic, and Cree have developed systems that are demonstrating that artificial sunshine can do the job just as well, if not better, than nature. For instance, Philips tailors its LEDs to provide specific light patterns that can encourage faster growth or greater nutrient content. Horticulture-specific wavelength LEDs can mimic nature’s light patterns at their most ideal. Panasonic’s venture has been so successful that the electronics company intends to produce 5% of Singapore’s leafy greens in the next few years. In 2016, the company produced 82 tons of greens, including radishes, lettuce, and chard, from a single 2,670-square-foot farm.

According to the Association for Vertical Farming, produce grown in indoor farms uses up to 98% less water than traditional agriculture. A variety of irrigation systems exist, including aeroponic misting technology, hydroponic facilities in which the growing medium is water instead of soil, and indoor fish farms in which the fish produce waste that becomes nutrients for the plants that grow in the fish tanks.

“Indoor farming depends entirely on energy produced by technology. Lighting, HVAC, hydroponics, watering systems, and testing systems that monitor nutrients. Sensor and control technology that makes sure the dew points and temperatures are within range for optimal growing conditions. Everything depends on an interconnected system that is plugged into an energy source,” said Kathleen Hokanson, president of Koan Energy Consultants.

Hokanson managed energy for national multi-site retailers in the US and Canada before moving into business development for Philips. When medical cannabis became legalized, she realized the emerging industry needed to carefully manage its substantial energy usage and costs, and founded Koan. Regional large-scale indoor agricultural farming is the next frontier, she says. Technology will need to continually evolve to efficiently and strategically deliver energy for an environment suitable for plants to grow inside. Some growers are choosing to take it a step further by creating their own power onsite using renewable energy sources or combined heat and power (CHp).

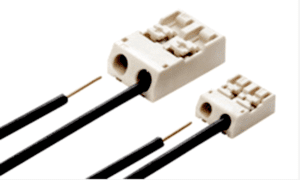

Molex Lite-Trap Connectors (Photo Credit: Molex)

Electronic companies are incorporating time-proven connector and sensor technologies, as well as developing specialized connectors, sensors, and IoT systems to bring energy to the lighting, monitoring, and irrigation technologies involved with indoor farming. Molex’s Lite-TrapTM and Mini Lite-TrapTM SMT wire-to-board connectors help lighting designers manage the complex illumination, power, and sensing requirement by streamlining interconnect systems.

AVX 70-9159 STRIPT Contacts for LED lighting. (Photo Credit: AVX Corp.)

When electronically connected via an M12 connector, Ifm efector’s SV Series Vortex Flow sensor and intelligent encoders provide reliable flow and temperature monitoring of circulating cooling water. Intermatic makes an electronic timer that controls the amount of light crops receive during their growing period, and the m-u-t Group develops monitoring systems that measure light output, water quality, nutrient content, and plant health. Heliospectra makes a lighting system that combines LEDs with optics, remote sensing techniques, and a heat dissipation solution, and AVX’s line of STRIPT™ UL-certified, uninsulated single-contact solutions are especially designed to meet the stringent cost, performance, height profile, and robustness specifications required for harsh industrial, commercial, and SSL applications like these as well. The opportunities for connector companies to join this rapidly growing industry are abundant.

Through the strategic delivery of energy, electronic systems are enabling urban farmers to reach their local populations quickly. With technology, agriculture is now possible year-round, in every climate, which is effectively reducing supply chain costs and bringing fresher, more delicate, local, and even organic vegetables to consumers and restaurants, even in the hearts of the busiest cities.

Recently posted:

[related_posts limit=”10″]

- Where in the World is Amphenol LTW’s Luc Kan? - April 23, 2024

- TE Connectivity’s Sustainability Efforts Pay Off - April 23, 2024

- What is a VGA Connector? - April 23, 2024