How to Specify Heavy-Duty Connectors and Cable Assemblies for Harsh Industrial Applications

Designing and specifying cable assemblies for use in harsh environments presents a number of challenges. Industrial equipment can be subjected to harsh conditions, such as high temperatures, water, high humidity, particulate ingress, electromagnetic interference (EMI), vibration, and impact from close proximity to moving factory components. Over time, exposure to these conditions begins to impede assembly conductivity and can require the replacement of cabling or, worse, the expensive equipment. HDC

Heavy-duty connectors (HDCs) are a good choice for harsh-environment industrial applications such as food and beverage or oil and gas processing. HDC systems provide almost unlimited connection options inside a heavy-duty industrial housing. These versatile housings are designed to industrial standards, ranging from IP to NEMA ratings, that quantify the degree to which an assembly can withstand harsh conditions. For instance, an IP65 housing would be sufficient for exposure to dust and potential water spray, however, a higher rated IP69 housing would be required for an exceedingly wet environment or water submersion. Housing material flexibility is another benefit to choosing an HDC assembly. For instance, the best housing material for reducing or eliminating the impact of a wet environment on a connector is plastic. However, if an assembly will be installed on moving equipment, it may be necessary to house the connectors in a stronger material, such as aluminum die-cast housings with NEMA 4X or UL-4 ratings to minimize impact damage. Additionally, if there are shielding concerns, designers can select a housing with an integrated filter that can reduce or eliminate electromechanical interference (EMI) from surrounding equipment.

This Weidmuller HDC harness plugged into mating RockStar bulkhead assemblies creates an IP65 connection between enclosures.

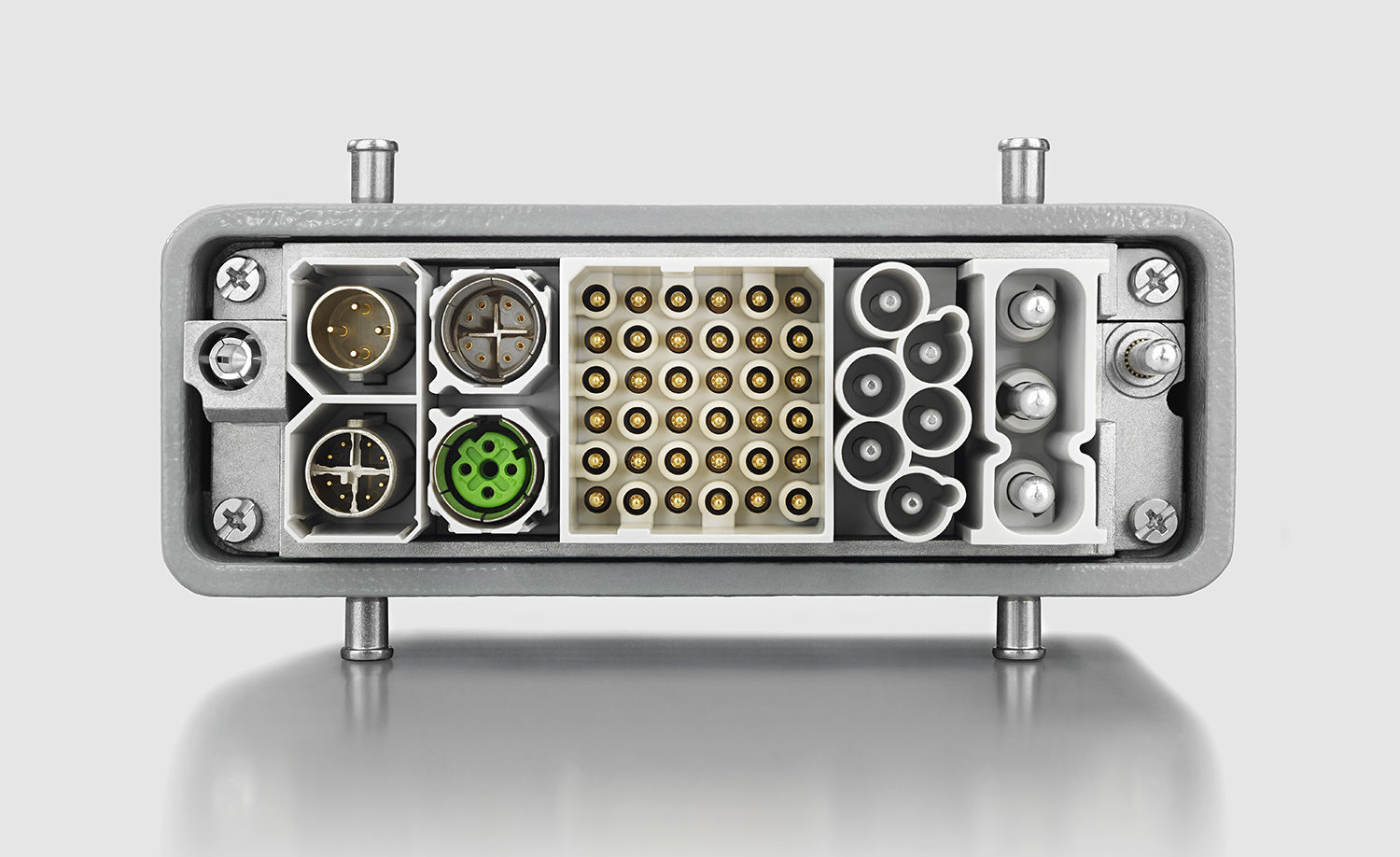

Once the protective housing type has been selected for the application, the housing size will be determined by a hybrid combination of pluggable inserts that are required to carry power, signal, or data to or from factory equipment. This is where HDC systems are uniquely positioned to meet the demands of the hybridization trend in pluggable cabling for industrial manufacturing, which is a result of increased consumer demand for customized products that require more flexible, decentralized manufacturing processes. This increased flexibility requires more functionality at device or factory equipment connection points rather than at a central control cabinet. As such, hybrid HDC solutions that offer a combination of power, data, and signal in one connector are in high demand.

A hybrid HDC connector assembly featuring Weidmuller’s ModuPlug modular inserts for providing data, signal, and power connections.

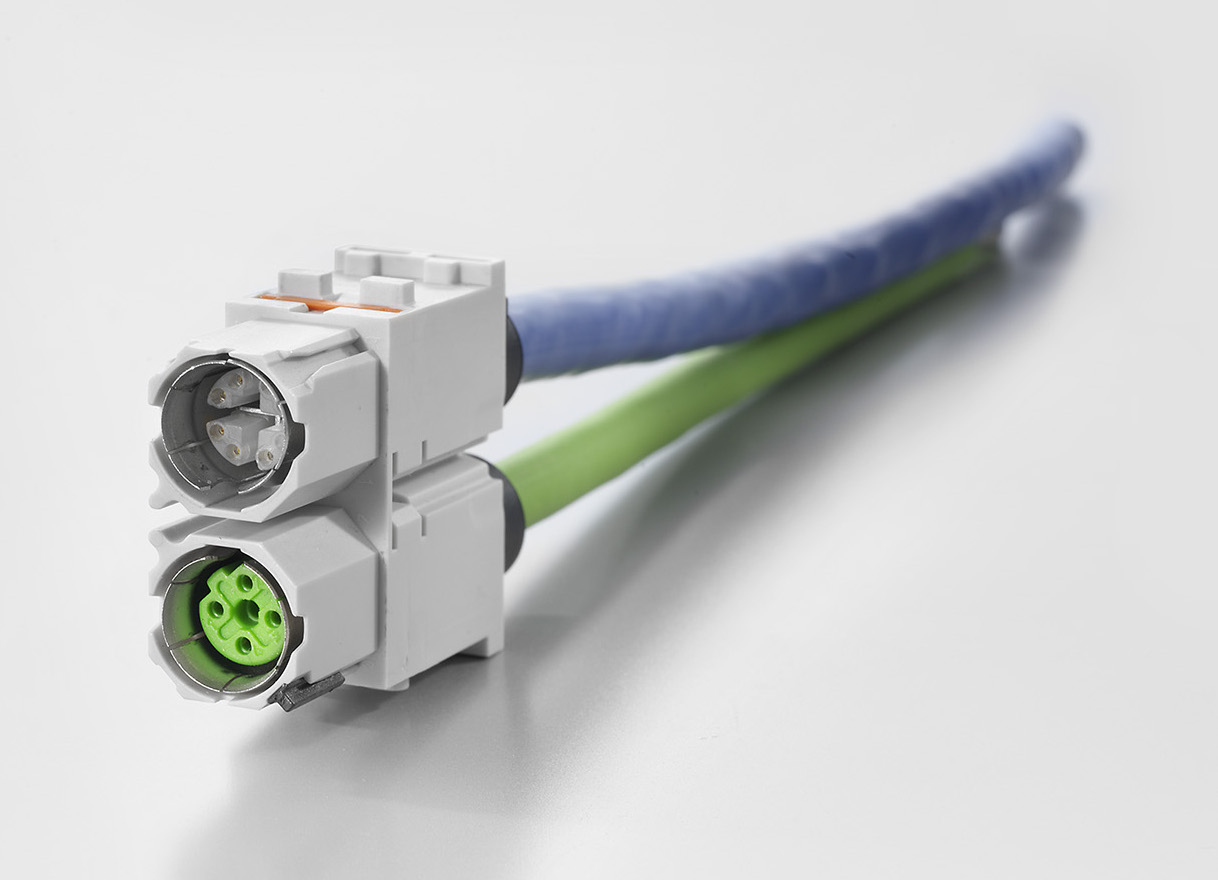

Modular HDC inserts provide an integrated hybrid assembly that creates new considerations for power and signal wiring beyond the fundamentals of approval ratings, wire gauge, and clamping type. Options for insert type can include, but are not limited to, RJ45, M12, USB, D-Sub, fiber optic, pneumatic (with or without a stop valve), high-density signal, and high-current power connections. Data connector selection requires an understanding of data speeds and conformity with established industrial protocols that include CIP, PROFINET, and PROFIBUS. Cable length has always been a factor for power transmission, but it can also determine the use of Ethernet-compatible cabling systems like Cat. 5, Cat. 6, or for very long cables, fiber optics. With the use of diverse contact types, it is also important to consider the assembly build process. For example, if a lack of diverse crimp tools or termination knowledge is a concern, consider specifying terminated data cable sub-assemblies or outsourcing the cable harness build. In this case, it would be beneficial to select an HDC manufacturer that can provide cabling value-added services.

A Weidmuller ModuPlug data insert module with Cat. 5 and Cat. 6 cables wired to two corresponding M12 connections.

Ingress protection (IP) ratings are another key concern for hybrid assemblies in harsh-environment applications. In hybrid systems, cables that provide air, signals, power, or data are threaded through a single cable gland. Multiple cables fed through one circular gland can leave a gap at the gland entry point and this gap can allow dust or moisture to enter the housing and make it challenging to maintain the hybrid assembly’s IP rating, but there are several available solutions. One solution is to submit every assembly to an environmental test prior to use in order to ensure that its IP rating is maintained. This testing should be conducted in addition to the typical testing performed on the data, signal, and power connections. Heavy-Duty Connectors

The available options for maintaining ingress protection via a single cable entry point into a protected housing include the use of cable gland grommets or conduit. A grommet or insert fitted inside a cable gland will seal the opening around each individual cable to maintain the assembly’s IP rating. However, it is important to note that options may be limited based on the number of cables and the size of the housing opening. If cable gland grommets are not an option, many types of plastic or metal conduit can be attached to an HDC cable gland via an adapter. When cables are run through conduit, it is important to adhere to the National Electrical Code (NEC) maximum fill percentages for the application to prevent overfilling the conduit. Some manufacturers offer standard housings with multiple threaded gland openings, while others can customize a housing to customer specifications. Customization can offer a simpler solution to design; however, it can also add cost and time to a project. Heavy-Duty Connectors

This custom HDC housing from Weidmuller maintains its IP65 rating with the addition of optional additional threaded cable gland entry points.

Heavy-duty connectors offer diverse connection options and environmental protections that can provide a pluggable answer to the demand for increased flexibility in a wide range of industrial manufacturing application. In fact, the almost unlimited options available for hybrid HDC cable assemblies may seem overwhelming. To address the increased complexity of specifying HDCs for harsh-environment industrial manufacturing, several manufacturers provide guidance via online tools, configurators, and technical support services. For the best results, always start with a clear list of application requirements to narrow the focus and help specify the right inserts and housing. For further support, contact a trusted manufacturer’s value-added department.