Improve Crimp Quality to Increase Productivity

Poor crimps can slow down a production line. Schleuniger explains how to improve crimp quality to increase productivity.

Micrograph cross section analysis of a quality crimp

A high quality crimp termination will usually exceed the service life of the product in which it is installed. On the other hand, a marginal quality crimp termination can cause electrical failures early in a product’s life. Crimp quality is of paramount importance, since a high percentage of product failures can be traced to poor electrical connections.

There are many factors that come into play that affect crimp quality. Knowing the relevant factors and to what extent each factor affects the end result will help to guide the process engineer toward achieving the best possible results.

Wire/Terminal Combination

The best place to begin the journey to improved crimp quality is to review the wire and terminal combination. The terminals must be made from quality materials and have very tight tolerances. Variation in material stock thickness will make it more difficult to monitor the in-process crimp quality. Some terminals are rated to handle three or four wire sizes. Usually these terminals work well for the middle wire sizes, but the results are marginal for wire sizes at either end of the spectrum. Crimping a 24AWG wire in a terminal rated for 20 to 24AWG might not work as well as crimping a 24AWG wire in a terminal rated for 24 to 28AWG. Handling terminal reels gently to prevent the terminals from getting bent will go a long way to improving how well the terminal is positioned over the anvil before crimping.

Consistent Crimp Height/Width

To obtain consistent high-quality results, you need a crimping press that provides a repeatable shut height under load and has a consistent crimping speed. These are fundamental criteria that should be held constant so that it will not add any variation to the crimping process.

The crimp applicator tooling must provide a crimp that meets the manufacturer’s specifications for crimp height and crimp width. Check the crimp height and perform a pull test to determine if the crimped wire and terminal combination are within the terminal manufacturer’s specification.

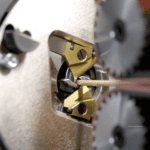

Crimp Micrograph

Going one step further, a crimp micrograph is the best way to analyze what’s going on inside of the crimp barrel. It allows you to see voids due to undercompression, count strands, check symmetry, and take several other measurements that determine whether a crimped termination is acceptable or not. More and more OEMs require crimp micrographs (in addition to crimp height and pull tests) to verify and document these additional parameters.

Crimp Force Monitor

Once you’ve checked crimp height, performed a pull test, and performed a micrograph, actual production can begin. The only way to monitor in-process quality is to use a crimp force monitor (CFM) to monitor the crimp force of each and every crimp. There are many factors that affect successful implementation of crimp force monitors, but that is beyond the scope of this article. However, the applicator and press quality play a huge role in CFM reliability and effectiveness. An applicator and/or press that is in poor condition will introduce variation (noise) that the CFM will see, reducing its ability to detect a good versus bad crimp. The best way to ensure that your CFM has the best chance for success is to implement a regular maintenance plan for your crimping presses and applicators.

Increased Productivity

So how can improved crimp quality increase productivity? The short answer is that by addressing all of the factors that can reduce crimp quality up front, there will be fewer defective crimps produced. In a fully automated machine, the CFM will detect whether a crimp is out of tolerance. If so, the machine will cut the crimped terminal off of the wire and eject the defective wire into the collection tray. This is done so operators cannot mix bad product with good product. The machine will make a new wire assembly to replace the defective one. The time and material spent to produce a defective wire assembly is a complete loss.

There is a cost for good crimp quality and it requires an investment in high-quality equipment and tooling as well as an ongoing preventive maintenance program. By building quality into the process and doing things right the first time, rejects and rework are reduced and productivity is greatly increased. In almost all cases, the return on investment for good quality is very short and the dividends continue paying out indefinitely.

Pete Doyon is vice president, product management, at Schleuniger.

Pete Doyon is vice president, product management, at Schleuniger.