Industrial Interconnects Enable Advanced Process Controls in the Fresh Water Industry

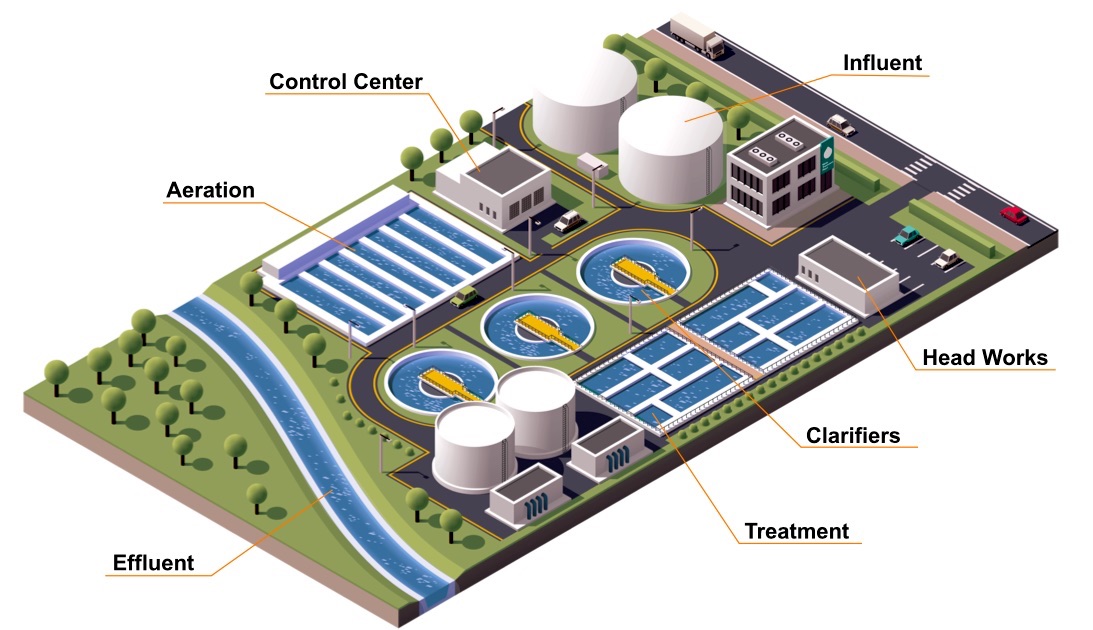

Desalination and wastewater treatment plants are becoming more efficient and cost-effective with the use of automated control systems and rugged and resilient electronics that can endure immersion and corrosion.

The availability of fresh water is easy to take for granted where it’s readily available, but water security is a growing global concern. Climate change, population growth, overdevelopment, and pollution threaten freshwater resources for billions of people. Water desalination processes are increasingly being used to meet the demand for fresh water. By removing the dissolved minerals in seawater, brackish water, and even wastewater, this technology produces fresh water for society and agriculture.

Whether or not desalination will be key to solving global problems of water security depends in part on its cost-effectiveness and environmental impact. In parts of the world that naturally lack abundant fresh water, desalination plants have been relied upon for decades. Countries in the Middle East and Eastern Mediterranean have long been innovators in the development of effective desalination technologies. Tiny and arid Israel, for example, has been a market leader in the development of desalination plants. Since the early 2000s, the country has massively expanded its desalination capacity and has committed to providing 70% of the country’s fresh water through desalination by 2050. The country’s Sorek desalination plant is one of the most advanced and cost-effective in the world, as well as one of the most productive, producing 624,000 cubic meters of fresh water per day. The plant achieved its high efficiency and output by deploying advanced process control technology coupled with an array of programmable automation controllers.

Thin Margins Demand Efficient Solutions

The high cost of building and operating desalination plants means that the water they produce is quite expensive and, consequently, that the opportunity to recoup investment costs in the technology is narrow. Investing in advanced process control technology and factory automation methodologies can help decrease costs in the long run, but the initial expense can still be prohibitive.

The Sorek plant addressed these issues through a lean process control system with minimal engineering and hardware costs. Rockwell Automation integrated programmable logic controllers into its own process control system to streamline plant functions. A high-speed Ethernet/IP industrial network protocol minimized the amount of hardware required to automate key processes, as well as engineering and operational costs, making it economically viable to utilize advanced process controls. These new digitalization and connectivity technologies ultimately reduced the price of the water the Sorek plant produces.

The achievements at the Sorek plant are indicative of a larger reality in industrial automation: Advancing software capabilities for process control technologies are nudging the requirements for the hardware layer toward leaner networks with higher data throughputs. Rugged and resilient new connectivity solutions enable this to occur even in harsh operating environments like desalination plants.

How to Install Wiring in a Corrosive Environment

Seawater desalination of the type done at Israeli plants is the most challenging desalination scenario of all. Seawater is very salty, making the process of removing it difficult, and it’s also corrosive. Installing electronic systems in an environment exposed to constant briny spray requires rugged components that promise high ingress protection and designs that implement wireless technologies whenever possible. The Allen-Bradley I/O components used at Sorek are also temperature-resistant and treated with a conformal coating. This specialized polymer film is applied to electronics to increase moisture and dust resistance.

Sensata Technologies’ Cynergy3 product line includes level, pressure, flow, and temperature sensors (pictured here clockwise from top left), which can be used in desalination and wastewater treatment facilities, and other industrial applications. Distributors including Digi-Key Electronics, Mouser Electronics, Sager Electronics, and TTI Inc. carry Sensata’s Cynergy3 line.

Sorek opened in 2013. Since then, new technologies have matured that can solve multiple issues faced by the engineers who designed the original systems, including concerns around environmental resilience. In particular, great advancements have been made in sensor technologies that are key to automating industrial networks. Sensata Technologies’ Cynergy3 product line includes components that can endure submersion in corrosive liquids while delivering wireless technology. Wireless sensors offer the major advantage of ditching copper connections and network infrastructure altogether, avoiding component degradation in a salt air environment. Wireless components also have the potential to reduce overall component and cabling costs, which could amount to critical savings in thin-margin applications like desalination.

Water treatment facilities can operate more effectively and efficiently with industrial automation strategies. Weidmüeller works closely with the water industry to develop connectivity solutions that meet the unique needs of these demanding operating environments.

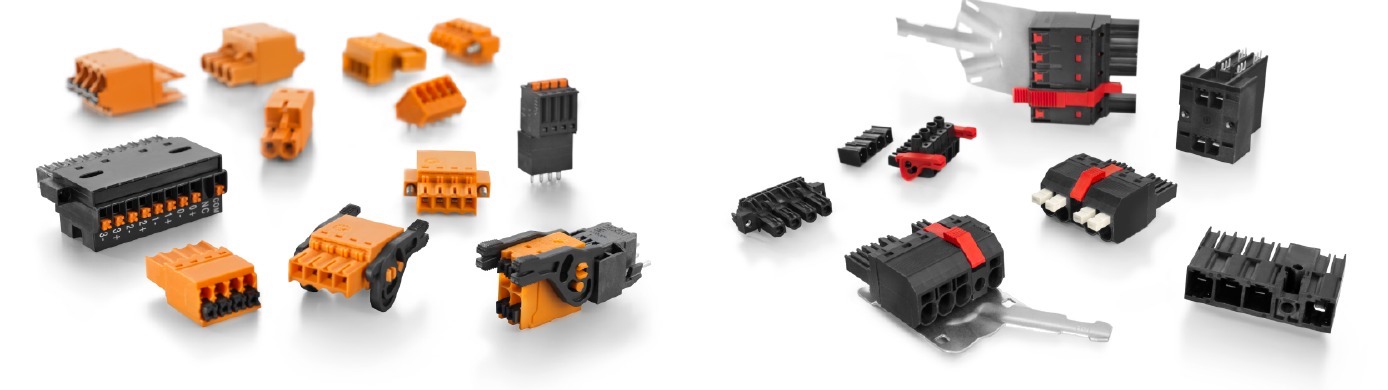

As use cases for industrial automation and process control continue to grow, harsh environment interconnects will play a key role. Weidmüller is one connector company that has developed application-specific products for the automation of water and wastewater treatment plants, including high-speed interconnects used in intelligent process data processing and analysis, products for early error detection (condition monitoring), and industrial Ethernet networks specially designed for applications in the water industry. Weidmüller’s water and process industry solutions also include pluggable push-in and screw clamp terminals, heavy-duty connectors, and specialized Industrial Ethernet solutions.

Weidmüller’s rugged and scalable OMNIMATE Signal and OMNIMATE Power portfolios serve demanding water industry applications with power, signal, data, Power BUS, and PCB terminals and connectors. OMNIMATE products offer modular configurability to meet the unique needs of specific applications and wiring strategies.

Can Better Electronics Make Desalination Easier to Adopt?

Desalination is a critical component in the fight for water security, especially in areas that are already naturally arid. Advancing electronics for process control networks will help make desalination more economically viable but concerns remain. Seawater desalination in particular results in vast amounts of concentrated waste brine that is returned to the sea. As the cost of traditionally sourced water increases in coming decades, desalination may become more imperative. This is a problem that electronics alone cannot solve, but accelerating innovation could further reduce costs and environmental impacts.

In the meantime, civil engineers and public officials continue to think creatively about water recycling and desalination, which has applications beyond the rather daunting application of turning seawater into fresh water. Desalination technologies can also be used to treat brackish water and can do so at a lower cost than treating seawater. Connector companies like Weidmüller may have a lot of expertise to offer at the convergence of wastewater treatment, desalination, and the larger water recycling strategy. This wider strategy is at the core of the success of water security projects like Israel’s, which deploys advanced process controls for its larger water grid and combines desalination with wastewater recovery to, remarkably, generate a water surplus in a very arid environment.

Like this article? Check out our other automation, harsh environment, and waterproof connectivity articles, our Industrial Market Page, and our 2021 and 2020 Article Archives.

- 30 Years of Automotive CAN - March 30, 2021

- Industrial Interconnects Enable Advanced Process Controls in the Fresh Water Industry - February 23, 2021

- Remote Work Opens Network Infrastructures to Security Risks - December 8, 2020