Interconnect Solutions Drive the Evolution of Rail Mobility

Core rail interconnect innovations have supported transportation industry goals to provide faster, safer, and more comfortable services.

By Chiara Pieri, Marcom Manager, Tom Kannally, Product Specialist – Connectors, Riadh Gazdallah, Commercial Connectors Product Manager, Smiths Interconnect

The need and desire for faster, safer, and more comfortable rail services has grown significantly in the past two decades, and the rail industry has seen exponential growth in the use of technology to advance sophisticated rail transportation systems. The performance of rail interconnect technologies is critical to designing systems that offer passengers an exceptional traveling or commuting experience.

The rail market has seen great technological evolution across every aspect of operations, from passenger experience to higher travel speeds to more connected operations and communications. Connector manufacturers have continually delivered the state-of-the-art connectivity solutions needed to implement the many complex arrays of electronic and electrical systems used in modern rail design. The demand for reliability is imperative to all connected systems that are part of railway transportation, including safety, control, and command systems, as well as power distribution, data transmission, and interfaces with transportation infrastructure systems.

A number of core interconnect competencies have enabled connector suppliers to support rail industry goals to provide faster, safer, and more comfortable services through reliable technologies. These include developing high-performance products with qualified materials, employing flexible designs to meet the most stringent rail environmental requirements, and utilizing proven engineering and manufacturing capabilities through qualified original equipment manufacturer (OEM) partners. These key factors support the confidence manufacturers in the rail industry have vested in trusted connector suppliers to develop the right connection solutions for their development programs.

Connector suppliers that specialize in the rail market understand the key importance of connectivity solutions that can provide high reliability, even under high levels of shock and vibration, which is the standard continuous operating condition for this industry. The industry has responded with shielded connections that address electromagnetic interference (EMI) and radiofrequency interference (RFI) and hybrid connections capable of combining signal, power, RF, and high-speed data in a single housing to satisfy space and weight constraints and other key application needs. These companies’ portfolios of diversified products for the rail market have been developed by establishing long-term, win-win partnerships with global manufacturers.

A new generation of highly reliable connectors has been integral to the development of advanced rail technologies. These products feature rugged, heavy-duty packaging designed for the harsh environment conditions that typify rail operations and facilitate the rigorous connectivity needs of technologies across every point in the rail system.

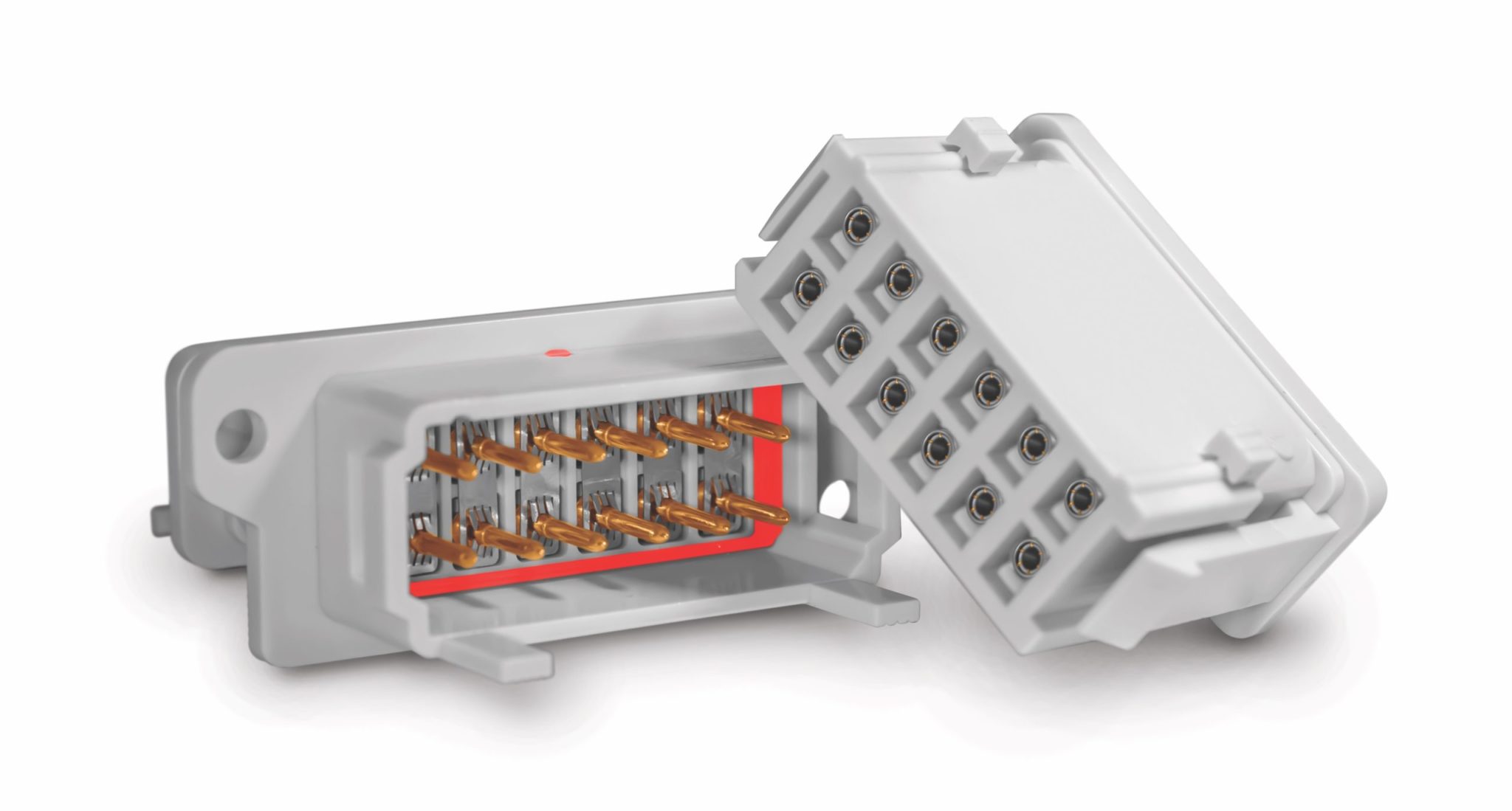

Quick-mating rectangular multipole plastic connectors have been developed to meet the most stringent requirements of the rail transportation industry, including electrical, mechanical, and environmental performance through appropriate materials and contact technology. These connectors comply with fire and smoke standards, including NF F 61-032, EN 45545-2, and EN ISO 11925-2, as well as French National Railway Company (SNCF) standards. Full plastic solutions, offered in either cabled or PCB mounting options, provide rapid assembly and fast mating without requiring additional mounting hardware to quickly install into the system. This makes maintenance much easier and allows the same connectors to be used in multiple applications, such as windshield wiper, door control, lighting, and power supplies for passengers.

REP Series environmentally sealed, quick-mating multipole rectangular plastic connectors by Smiths Interconnect make maintenance fast and easy in rail applications.

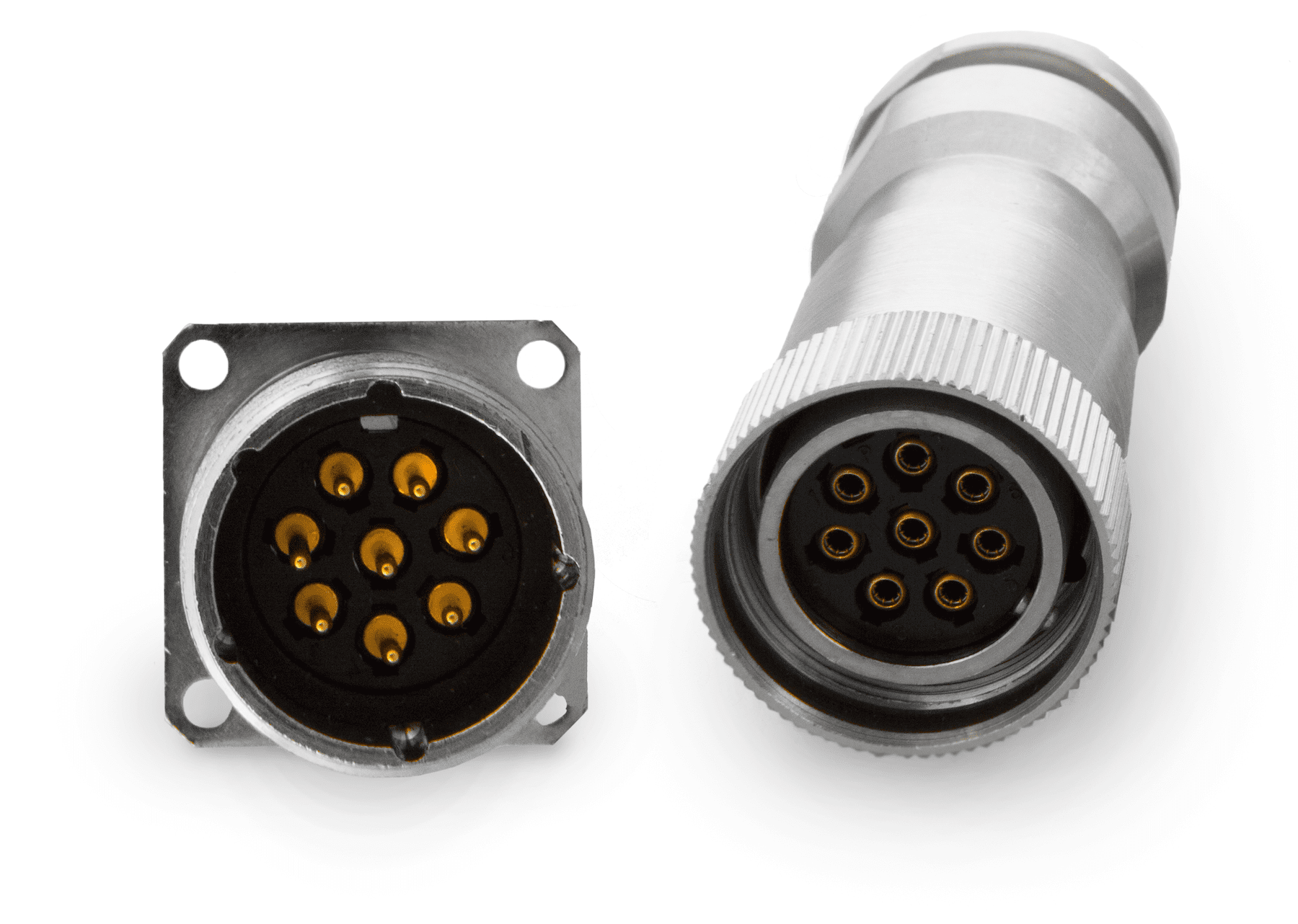

Metal circular connectors are suitable for automated train operation and traffic controls, as well as the braking system. These can offer robust sealed body shells with mechanical keying systems to ensure safe mating, cable clamps with large cabling chambers to allow various cable diameters, and shielding for EMI and RFI protection. They can also typically be ordered as cable assemblies to provide a complete interconnect solution at a lower cost of ownership.

C Series EMC metallic circular connectors by Smiths Interconnect offer shielding for EMI and RFI protection.

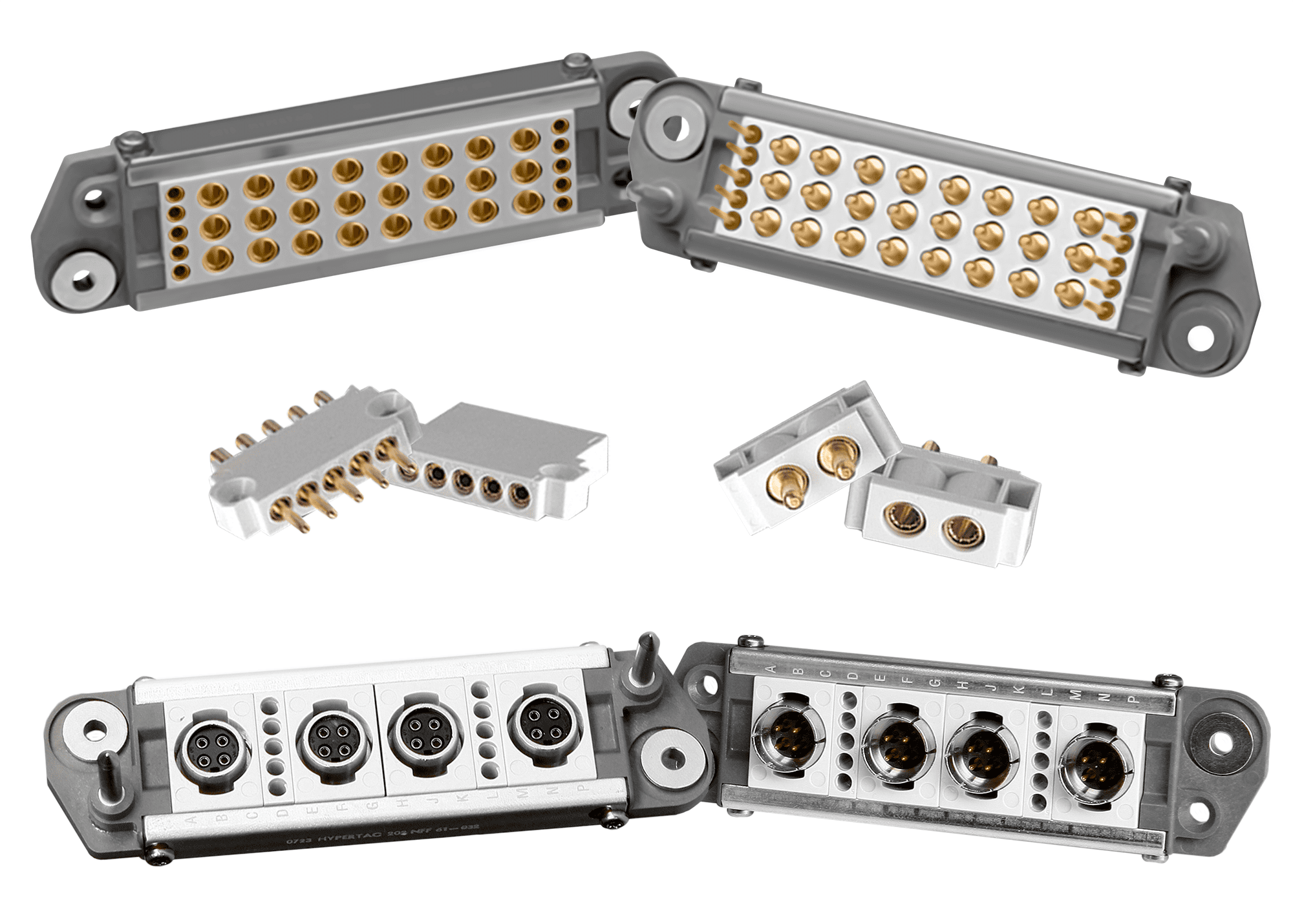

Modular connectors typically offer the widest and most versatile ranges in an interconnect portfolio, offering cost-effective customization and lead-time benefits. These rugged connector solutions can be equipped with signal, power, coax, and data communication contacts and come in frames of various lengths to accommodate a variety of module combinations. Modular, high-density rack and panel connectors are available in configurations that can be compliant to EN 45545, NF F 61-032, and SNCF standards and are used in demanding applications where durability, ruggedization, and extended operating life are crucial. For example, they are often used within onboard safety control and command cabinets and incorporated into track and station cabinets, thanks to their material performance, reliable contact technology, and floating contact design that enables blind mating.

LHS/LHZ Series rack and panel blind mating modular connectors

These connectors are designed with proven contact technologies including hyperboloid contacts to enable low mating force, low electrical resistance, and robust resistance to adverse environmental conditions. These features help ensure excellent reliability, even under the high levels of shock, vibration, and mating cycles common to the rail industry. Quality rail connectors deliver high current ratings while meeting stringent overvoltage EN rail standards and ensuring safe, secure, and effective installation and operation.

For more information, visit Smiths Interconnect online.