Circular Connector Products

This week’s Product Roundup highlights circular connectors from leading suppliers.

Air Electro, Inc. stocks SOURIAU’s 8D Series MIL-DTL-38999 Series III connectors. Designed for harsh-environment military and commercial aerospace, defense, industrial, and transportation, applications, the series features 360° EMI shielding, IP67 sealing on each contact cavity, scoop-proof contacts, a metallic contact retention clip, a self-locking quick-coupling mechanism for easy installation, visual mating confirmation, and rugged resistance to high vibration (44g) and operating temperatures up to 200°C. The versatile series is available in nine shell sizes spanning 9–25, seven contact sizes spanning #4–26, and 54 MIL-DTL-38999-qualified layouts with 1–128 gold-over-nickel-plated copper alloy contacts and PC tail, crimp, solder cup, and wire wrap terminations. The series also offers five shell materials: aluminum, composite, stainless steel, titanium, and bronze; five plating materials: nickel, black zinc nickel, green zinc cobalt, cadmium olive drab, and passivated stainless steel; multiple signal, high-power, and high-speed contact technologies, including coax, quadrax, twinax, triax, ELIO® fiber optic, and expanded beam; and accessories including protective caps, backshells, and tooling. Additional options include hermetic versions, current ratings up to 850A, voltage ratings up to 230V, and endurance up to 1,500 cycles. The series is qualified to MIL-DTL-38999, EN3645, and BACC63 specifications.

stocks SOURIAU’s 8D Series MIL-DTL-38999 Series III connectors. Designed for harsh-environment military and commercial aerospace, defense, industrial, and transportation, applications, the series features 360° EMI shielding, IP67 sealing on each contact cavity, scoop-proof contacts, a metallic contact retention clip, a self-locking quick-coupling mechanism for easy installation, visual mating confirmation, and rugged resistance to high vibration (44g) and operating temperatures up to 200°C. The versatile series is available in nine shell sizes spanning 9–25, seven contact sizes spanning #4–26, and 54 MIL-DTL-38999-qualified layouts with 1–128 gold-over-nickel-plated copper alloy contacts and PC tail, crimp, solder cup, and wire wrap terminations. The series also offers five shell materials: aluminum, composite, stainless steel, titanium, and bronze; five plating materials: nickel, black zinc nickel, green zinc cobalt, cadmium olive drab, and passivated stainless steel; multiple signal, high-power, and high-speed contact technologies, including coax, quadrax, twinax, triax, ELIO® fiber optic, and expanded beam; and accessories including protective caps, backshells, and tooling. Additional options include hermetic versions, current ratings up to 850A, voltage ratings up to 230V, and endurance up to 1,500 cycles. The series is qualified to MIL-DTL-38999, EN3645, and BACC63 specifications.

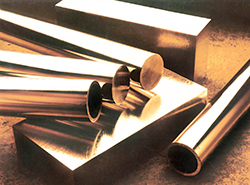

Materion ’s high-performance Alloy M25 provides the highest strength of any copper beryllium alloy on the market and significantly outperforms other high-strength copper alloys in terms of electrical and thermal conductivity. It also offers high fatigue strength, high resistance to wear, corrosion, galling, and stress relaxation, and excellent machinability due to the inclusion of lead. Ideal for the fabrication of circular and coaxial connector contacts employed in automotive, aerospace, and other heavy-duty, harsh-environment electronics applications — and especially those that require stability to 175°C or consistent contact force in miniaturized designs — Alloy M25 also minimizes signal distortion in coaxial RF connectors, reduces power loss in circular connectors and contact probes, and provides superior reliability compared to other free-machining copper alloys. Alloy M25 is available in spooled wire, coiled wire, and rod product forms, as well as in different tempers to accommodate a diverse range of design requirements, and after machining and forming operations, M25 parts can easily be heat treated and plated to achieve maximum mechanical and electrical performance.

’s high-performance Alloy M25 provides the highest strength of any copper beryllium alloy on the market and significantly outperforms other high-strength copper alloys in terms of electrical and thermal conductivity. It also offers high fatigue strength, high resistance to wear, corrosion, galling, and stress relaxation, and excellent machinability due to the inclusion of lead. Ideal for the fabrication of circular and coaxial connector contacts employed in automotive, aerospace, and other heavy-duty, harsh-environment electronics applications — and especially those that require stability to 175°C or consistent contact force in miniaturized designs — Alloy M25 also minimizes signal distortion in coaxial RF connectors, reduces power loss in circular connectors and contact probes, and provides superior reliability compared to other free-machining copper alloys. Alloy M25 is available in spooled wire, coiled wire, and rod product forms, as well as in different tempers to accommodate a diverse range of design requirements, and after machining and forming operations, M25 parts can easily be heat treated and plated to achieve maximum mechanical and electrical performance.

NorComp ’s M5 Series circular connectors offer versatile solutions for a wide range of demanding applications including transportation and control systems, automated doors and ramps, sensor connectivity, and data and communications systems. They have a compact and robust IP67/68 cable-to-panel interface that provides high-reliability signal transmission, UL94 V-0 insulators, nickel-plated brass shells, and 2–4 gold-plated brass (male) or phosphor bronze (female) non-removable solder cup, vertical through-hole, or right-angle contacts. The series is available in shielded and unshielded versions, is compliant with RoHS2, and is rated for operating temperatures spanning -40°C to +85°C. It is also available with an optional dust cap and as either loose pieces or premade cables.

’s M5 Series circular connectors offer versatile solutions for a wide range of demanding applications including transportation and control systems, automated doors and ramps, sensor connectivity, and data and communications systems. They have a compact and robust IP67/68 cable-to-panel interface that provides high-reliability signal transmission, UL94 V-0 insulators, nickel-plated brass shells, and 2–4 gold-plated brass (male) or phosphor bronze (female) non-removable solder cup, vertical through-hole, or right-angle contacts. The series is available in shielded and unshielded versions, is compliant with RoHS2, and is rated for operating temperatures spanning -40°C to +85°C. It is also available with an optional dust cap and as either loose pieces or premade cables.

TT Electronics ’ ABCIRH Series halogen-free bayonet-locking connectors are based on the American MIL-C-5015 and the German VG95234 specifications, are interchangeable with all corresponding connector types, and are widely employed in mass transportation, entertainment, and general industrial applications. They have stainless steel anti-wear pins at the critical point of the receptacle coupling ramps to enhance service life in high-vibration and high-mating-cycle applications, visible alignment guides on both the receptacle and the coupling nut of the plug connector to prevent mismating, and a three-pin bayonet coupling mechanism with audible coupling confirmation. Additional features include MIL-STD-1651 contact arrangements with 1–95 silver- or gold-plated copper alloy contacts, solder or PC-tail terminations, halogen-free, low-fire-hazard rubber insulators, and both a dynamic sealing ring under the coupling nut and an individual wire seal grommet at the rear of the connector to provide IP67 protection against water and dust ingress. The series is rated for 2,000 mating cycles, 13–150A, and operating temperatures extending from -55°C to +200°C, and is available with four standard plating finishes: olive drab chromate over cadmium plate, black zinc cobalt, green zinc cobalt, and black zinc nickel. A comprehensive range of backshells and accessories designed to ensure excellent continuity and EMI and RFI shielding characteristics is also available, and alternative finishes are available upon request.

’ ABCIRH Series halogen-free bayonet-locking connectors are based on the American MIL-C-5015 and the German VG95234 specifications, are interchangeable with all corresponding connector types, and are widely employed in mass transportation, entertainment, and general industrial applications. They have stainless steel anti-wear pins at the critical point of the receptacle coupling ramps to enhance service life in high-vibration and high-mating-cycle applications, visible alignment guides on both the receptacle and the coupling nut of the plug connector to prevent mismating, and a three-pin bayonet coupling mechanism with audible coupling confirmation. Additional features include MIL-STD-1651 contact arrangements with 1–95 silver- or gold-plated copper alloy contacts, solder or PC-tail terminations, halogen-free, low-fire-hazard rubber insulators, and both a dynamic sealing ring under the coupling nut and an individual wire seal grommet at the rear of the connector to provide IP67 protection against water and dust ingress. The series is rated for 2,000 mating cycles, 13–150A, and operating temperatures extending from -55°C to +200°C, and is available with four standard plating finishes: olive drab chromate over cadmium plate, black zinc cobalt, green zinc cobalt, and black zinc nickel. A comprehensive range of backshells and accessories designed to ensure excellent continuity and EMI and RFI shielding characteristics is also available, and alternative finishes are available upon request.

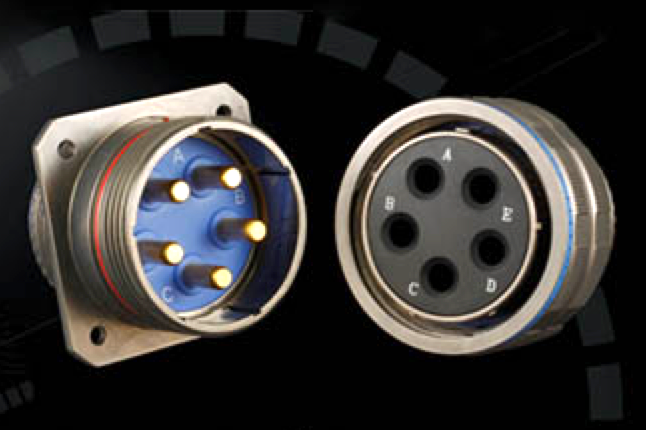

BTC Electronics builds circular D38999 Series III connectors from Conesys/Aero Electric to spec from stock. Used in high-performance military and commercial aircraft, missiles, communication equipment, and much more, the series features a one-turn coupling system with self-locking acme thread on the RFI grounding plug for durability, thick wall sections and a large coupling surface area for strength and shock resistance, firewall capabilities, a scoop-proof design, and superior contact stability. Wall-mount and jam nut receptacles are available, as are a range of finishes and shell materials, including anodic, zinc cobalt, aluminum, electroless nickel, olive drab cadmium.

builds circular D38999 Series III connectors from Conesys/Aero Electric to spec from stock. Used in high-performance military and commercial aircraft, missiles, communication equipment, and much more, the series features a one-turn coupling system with self-locking acme thread on the RFI grounding plug for durability, thick wall sections and a large coupling surface area for strength and shock resistance, firewall capabilities, a scoop-proof design, and superior contact stability. Wall-mount and jam nut receptacles are available, as are a range of finishes and shell materials, including anodic, zinc cobalt, aluminum, electroless nickel, olive drab cadmium.

JAE ‘s JL10 Series circular waterproof connectors have a compact, low-profile design with versatile cable entry orientations, IP67 sealing, rugged resistance against vibration and oil, and a hybrid threaded/one-touch mating mechanism. The bayonet-style one-touch mating mechanism reduces screw-down fastening, eliminates torque control, and establishes secure JL10 plug and receptacle connections in industrial applications with significant space constraints and limited visibility, as well as enables visible confirmation of proper mating via a white guide mark, while the threaded mating mechanism further extends mating compatibility to conventional MIL-standard MS connectors and JAE’s JL04V, N/MS, and JA screw-mating plugs. The series also offers individually waterproof receptacles and waterproof mated pairs, is rated for 500 mating cycles, and is UL recognized and TÜV approved. Additional options include eight cable entry orientations in 45° increments, four contact sizes and maximum current ratings (#4, 80A; #8, 46A; #12, 23A; and #16, 13A), six pin counts (4, 9, 17, 19, 22, and 37), and two termination options: solder terminations, which are available for all receptacles, and crimp terminations, which are available for pin arrangements 18-10 and 22-22.

‘s JL10 Series circular waterproof connectors have a compact, low-profile design with versatile cable entry orientations, IP67 sealing, rugged resistance against vibration and oil, and a hybrid threaded/one-touch mating mechanism. The bayonet-style one-touch mating mechanism reduces screw-down fastening, eliminates torque control, and establishes secure JL10 plug and receptacle connections in industrial applications with significant space constraints and limited visibility, as well as enables visible confirmation of proper mating via a white guide mark, while the threaded mating mechanism further extends mating compatibility to conventional MIL-standard MS connectors and JAE’s JL04V, N/MS, and JA screw-mating plugs. The series also offers individually waterproof receptacles and waterproof mated pairs, is rated for 500 mating cycles, and is UL recognized and TÜV approved. Additional options include eight cable entry orientations in 45° increments, four contact sizes and maximum current ratings (#4, 80A; #8, 46A; #12, 23A; and #16, 13A), six pin counts (4, 9, 17, 19, 22, and 37), and two termination options: solder terminations, which are available for all receptacles, and crimp terminations, which are available for pin arrangements 18-10 and 22-22.

Interstate Connecting Components (ICC) , a division of Heilind Mil-Aero, stocks Glenair’s Series 970 PowerTrip™ Connectors and Accessories for extreme environments. The high-ampacity, military-grade connectors are both smaller and lighter than lower-density 5015-type power connectors and deliver excellent mechanical, environmental, and electrical performance in harsh-environment applications including power distribution units, modern defense equipment, aerospace systems, hybrid electric drives, motors, and DC, single-phase AC, and three-phase AC power systems. Features include triple-start ACME threads for fast, easy mating, five polarizing keys and six keying positions, a rear-release crimp contact system with high-conductivity copper alloy contacts, a ratcheting coupling nut for secure mating, and aluminum, stainless steel, and passivated stainless steel shells. The series also features high-ampacity LouverBand socket contacts for reduced joule heating, stable resistance, and longer lifetime performance, a splined backshell interface for improved EMI protection, and five contact sizes: #8, #4, and #1/0 (standard) and #12 and #16 (last-make/first-break). Available styles include cable-mount plugs and receptacles, square flange, jam nut, and filtered jam nut panel-mount receptacles, and standard and hermetic jam nut feedthrough bulkhead receptacles in a full range of standard insert arrangement, and finishes include electroless nickel, nickel-PTFE, and black zinc-nickel. Operating temperatures for the series extend from -65°C to +200°C.

, a division of Heilind Mil-Aero, stocks Glenair’s Series 970 PowerTrip™ Connectors and Accessories for extreme environments. The high-ampacity, military-grade connectors are both smaller and lighter than lower-density 5015-type power connectors and deliver excellent mechanical, environmental, and electrical performance in harsh-environment applications including power distribution units, modern defense equipment, aerospace systems, hybrid electric drives, motors, and DC, single-phase AC, and three-phase AC power systems. Features include triple-start ACME threads for fast, easy mating, five polarizing keys and six keying positions, a rear-release crimp contact system with high-conductivity copper alloy contacts, a ratcheting coupling nut for secure mating, and aluminum, stainless steel, and passivated stainless steel shells. The series also features high-ampacity LouverBand socket contacts for reduced joule heating, stable resistance, and longer lifetime performance, a splined backshell interface for improved EMI protection, and five contact sizes: #8, #4, and #1/0 (standard) and #12 and #16 (last-make/first-break). Available styles include cable-mount plugs and receptacles, square flange, jam nut, and filtered jam nut panel-mount receptacles, and standard and hermetic jam nut feedthrough bulkhead receptacles in a full range of standard insert arrangement, and finishes include electroless nickel, nickel-PTFE, and black zinc-nickel. Operating temperatures for the series extend from -65°C to +200°C.

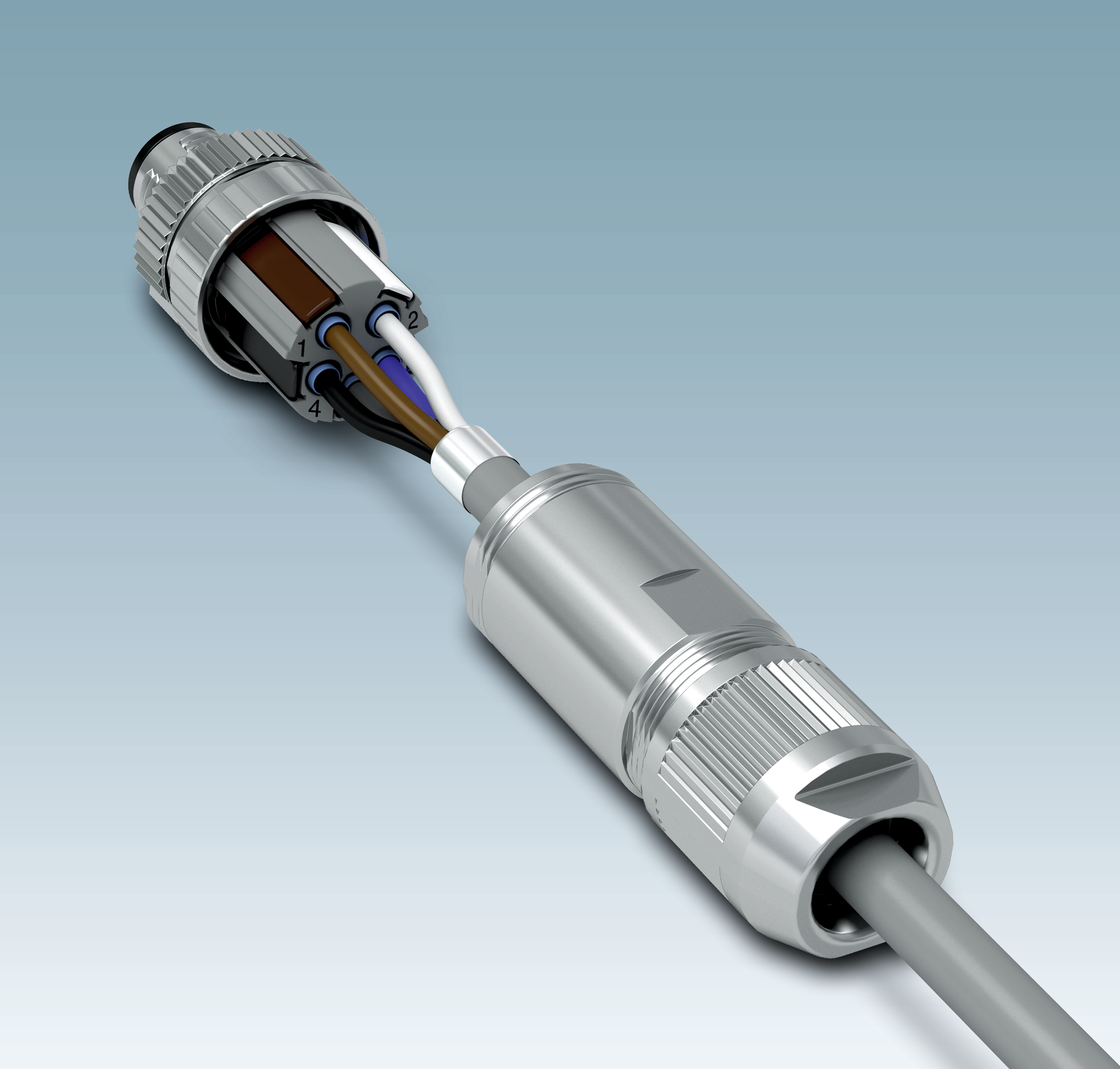

Siemon ’s M12 D-Coded Cable Assemblies for Ethernet and PROFINET industrial networks provide compact, robust, and reliable connections in harsh-environment applications including industrial automation equipment and switch, sensor, and control systems. The robust 26AWG cordsets combine a specially designed polyurethane (PUR) cable jacket with 360° shielding and an overmolded connector to provide IP67 ingress protection and protection from other common industrial elements, including EMI, chemicals, UV radiation, shock, vibration, and other mechanical stress. The assemblies are available with straight, angled, and RJ45 connector options, are rated for 100 plug insertion cycles and operating temperatures spanning -10°C to 75°C, and meet several industry specifications, including ANSI/TIA-568-C.2 Category 5e, ISO/IEC 11801 Ed 2.2 Category 5e, UL 1863 and CSA-C22.2 No 182.4, IEC 61076-2-101, RoHS, and UL94 V-0.

’s M12 D-Coded Cable Assemblies for Ethernet and PROFINET industrial networks provide compact, robust, and reliable connections in harsh-environment applications including industrial automation equipment and switch, sensor, and control systems. The robust 26AWG cordsets combine a specially designed polyurethane (PUR) cable jacket with 360° shielding and an overmolded connector to provide IP67 ingress protection and protection from other common industrial elements, including EMI, chemicals, UV radiation, shock, vibration, and other mechanical stress. The assemblies are available with straight, angled, and RJ45 connector options, are rated for 100 plug insertion cycles and operating temperatures spanning -10°C to 75°C, and meet several industry specifications, including ANSI/TIA-568-C.2 Category 5e, ISO/IEC 11801 Ed 2.2 Category 5e, UL 1863 and CSA-C22.2 No 182.4, IEC 61076-2-101, RoHS, and UL94 V-0.

Smiths Interconnect ’s MIL-DTL-38999 Differential Quadrax/Twinax Connectors and Cable Assemblies support data rates in excess of 2Gb/s data and bandwidth up to 3GHz, and can be driven via matched impedance differential pair interconnections for reliable, high-speed, board-to-board data transfer. Designed to enable the reliable, high-speed transfer of digital audio and video signals, the series is ideal for high-speed Ethernet, FireWire, and Fibre Channel applications in the commercial aerospace, defense, space, and railway markets, including avionics, engine, satcom, and soldier communications systems, intelligence, surveillance, and reconnaissance (ISR) systems, radar systems, satellite launchers, ground systems, and geostationary-, medium-, and low-Earth-orbit satellites. It also offers superior performance in high-speed matched impedance data-on-demand applications. The series’ signal-to-signal and signal-to-shield characteristic impedance is maintained throughout the connector pair, and its true twinaxial connector interface maintains signal integrity while minimizing jitter and data rate errors. Various shell styles, sizes, material/plating configurations, insert arrangements, contact types and terminations, and polarizations are available to support broad design flexibility.

’s MIL-DTL-38999 Differential Quadrax/Twinax Connectors and Cable Assemblies support data rates in excess of 2Gb/s data and bandwidth up to 3GHz, and can be driven via matched impedance differential pair interconnections for reliable, high-speed, board-to-board data transfer. Designed to enable the reliable, high-speed transfer of digital audio and video signals, the series is ideal for high-speed Ethernet, FireWire, and Fibre Channel applications in the commercial aerospace, defense, space, and railway markets, including avionics, engine, satcom, and soldier communications systems, intelligence, surveillance, and reconnaissance (ISR) systems, radar systems, satellite launchers, ground systems, and geostationary-, medium-, and low-Earth-orbit satellites. It also offers superior performance in high-speed matched impedance data-on-demand applications. The series’ signal-to-signal and signal-to-shield characteristic impedance is maintained throughout the connector pair, and its true twinaxial connector interface maintains signal integrity while minimizing jitter and data rate errors. Various shell styles, sizes, material/plating configurations, insert arrangements, contact types and terminations, and polarizations are available to support broad design flexibility.

Avnet stocks high-performance connector solutions from ODU, including ODU MEDI-SNAP® connectors, which are designed to enable the reliable transmission of signal, power, liquids, and gasses in a wide variety of medical, industrial, and test and measurement equipment. These circular, plastic, push-pull connectors are 75% lighter than comparable metal connectors, deliver IP67 protection when mated, are highly resistant to chemicals, and are compatible with autoclave and other sterilization processes. They have durable, space-saving, non-magnetic, and touch-proof plastic housings that enable simple plug assembly, versatile mechanical (pin-and-groove) and color-coded keying options, and a reliable push-pull locking mechanism. The range is available in two sizes with up to 26 positions, solder or PCB terminations, and optional EMC shielding, and is RoHS compliant and rated for more than 2,000 mating cycles. ODU MEDI-SNAP connectors are also offered in a unique right-angle plug configuration and as customized overmolded cable assemblies.

stocks high-performance connector solutions from ODU, including ODU MEDI-SNAP® connectors, which are designed to enable the reliable transmission of signal, power, liquids, and gasses in a wide variety of medical, industrial, and test and measurement equipment. These circular, plastic, push-pull connectors are 75% lighter than comparable metal connectors, deliver IP67 protection when mated, are highly resistant to chemicals, and are compatible with autoclave and other sterilization processes. They have durable, space-saving, non-magnetic, and touch-proof plastic housings that enable simple plug assembly, versatile mechanical (pin-and-groove) and color-coded keying options, and a reliable push-pull locking mechanism. The range is available in two sizes with up to 26 positions, solder or PCB terminations, and optional EMC shielding, and is RoHS compliant and rated for more than 2,000 mating cycles. ODU MEDI-SNAP connectors are also offered in a unique right-angle plug configuration and as customized overmolded cable assemblies.

Cinch Connectivity Solutions ’ EMI Filtered Connectors employ in-line circuitry to prevent unwanted RF noise and electromagnetic interference (EMI) from negatively affecting the performance of sensitive military and aerospace equipment, including avionics guidance systems, and glass-sealed packages to prevent leakage even when subjected to extreme changes in temperature, pressure, and humidity. The series can be integrated into virtually any of the company’s circular mil/aero connectors, including MIL-DTL-38999 and MIL-DTL-26482 styles, and offers a wide range of frequencies, insulation resistance, dielectric withstanding voltage, operating voltage, and capacitance for broad application suitability. Standard features include machined aluminum shells, planar array filter capacitors, and electroless nickel plating. Additional options include Pi, C, LC/CL, and T configurations; solder cup, crimp, and PC tail terminations; standard and low-profile panel-, board-, and flex-mount styles; and alternative plating options. Normal operating temperatures for the series span -55°C to +125°C.

’ EMI Filtered Connectors employ in-line circuitry to prevent unwanted RF noise and electromagnetic interference (EMI) from negatively affecting the performance of sensitive military and aerospace equipment, including avionics guidance systems, and glass-sealed packages to prevent leakage even when subjected to extreme changes in temperature, pressure, and humidity. The series can be integrated into virtually any of the company’s circular mil/aero connectors, including MIL-DTL-38999 and MIL-DTL-26482 styles, and offers a wide range of frequencies, insulation resistance, dielectric withstanding voltage, operating voltage, and capacitance for broad application suitability. Standard features include machined aluminum shells, planar array filter capacitors, and electroless nickel plating. Additional options include Pi, C, LC/CL, and T configurations; solder cup, crimp, and PC tail terminations; standard and low-profile panel-, board-, and flex-mount styles; and alternative plating options. Normal operating temperatures for the series span -55°C to +125°C.

Amphenol ICC ’s Rugged MRD Series Circular Locking Connectors provide reliable power or signal connections in harsh industrial, instrumentation, and medical applications including power generation equipment, smart grids, LED lighting, MRI and CT scanners, and ultrasound equipment. The sealed circular connectors offer IP67 protection against water and dust ingress, are rated for up to 10A and 500V to support high-power applications, and are available in 2-, 3-, and 4-position form factors to support design flexibility. Additional options include all-plastic constructions or locking metal housings with a one-third-turn bayonet locking mechanism or quick-release metal latches, panel-mount or cable terminations, and optional finger-proof protection. The series is rated for 500-cycle durability in operating temperatures extending from -55°C to +105°C and is compliant with RoHS and REACH/SVHC directives.

’s Rugged MRD Series Circular Locking Connectors provide reliable power or signal connections in harsh industrial, instrumentation, and medical applications including power generation equipment, smart grids, LED lighting, MRI and CT scanners, and ultrasound equipment. The sealed circular connectors offer IP67 protection against water and dust ingress, are rated for up to 10A and 500V to support high-power applications, and are available in 2-, 3-, and 4-position form factors to support design flexibility. Additional options include all-plastic constructions or locking metal housings with a one-third-turn bayonet locking mechanism or quick-release metal latches, panel-mount or cable terminations, and optional finger-proof protection. The series is rated for 500-cycle durability in operating temperatures extending from -55°C to +105°C and is compliant with RoHS and REACH/SVHC directives.

Phoenix Contact ’s compact M12 Connectors with Push-In Technology provide quick, reliable, tool-less connections for solid, stranded, and ferruled wire in a wide range of signal and data transmission applications. Ferruled and solid wires can be terminated using the push-in principle, an easy-open lever allows users to quickly connect stranded wires, and color coding further simplifies wiring processes. The series is available in pin-and-socket, straight, and right-angle configurations with 2–5 positions, A-, B-, and D-coding, optional shielding, and all-metal or all-plastic bodies, and can support a host of network protocols, including PROFINET, DeviceNet, CC-Link, and INTERBUS.

’s compact M12 Connectors with Push-In Technology provide quick, reliable, tool-less connections for solid, stranded, and ferruled wire in a wide range of signal and data transmission applications. Ferruled and solid wires can be terminated using the push-in principle, an easy-open lever allows users to quickly connect stranded wires, and color coding further simplifies wiring processes. The series is available in pin-and-socket, straight, and right-angle configurations with 2–5 positions, A-, B-, and D-coding, optional shielding, and all-metal or all-plastic bodies, and can support a host of network protocols, including PROFINET, DeviceNet, CC-Link, and INTERBUS.

LEMO ’s S Series straight plug and free socket connectors feature the company’s iconic chocolate block pattern, a push-pull self-latching mechanism, IP50 sealing, nine color codings, half-moon inserts, solder or print contacts, and the same collet as the B Series. They are available in three sizes (0S, 1S, and 2S) and four configurations (unipole, 50Ω and 75Ω coaxial, 50Ω and 75Ω triaxial, 2–10 contact multipole), are compatible with 1.4mm- to 9.9mm-diameter cable, are rated for operating temperatures extending from -55°C to 250°C, and are recognized by UL. They also deliver shielding performance greater than 40dB at 1GHz and greater than 75dB at 10MHz. Ideal applications for the series include broadcast, audio/visual, communications, test and measurement, battery, medical, and power equipment.

’s S Series straight plug and free socket connectors feature the company’s iconic chocolate block pattern, a push-pull self-latching mechanism, IP50 sealing, nine color codings, half-moon inserts, solder or print contacts, and the same collet as the B Series. They are available in three sizes (0S, 1S, and 2S) and four configurations (unipole, 50Ω and 75Ω coaxial, 50Ω and 75Ω triaxial, 2–10 contact multipole), are compatible with 1.4mm- to 9.9mm-diameter cable, are rated for operating temperatures extending from -55°C to 250°C, and are recognized by UL. They also deliver shielding performance greater than 40dB at 1GHz and greater than 75dB at 10MHz. Ideal applications for the series include broadcast, audio/visual, communications, test and measurement, battery, medical, and power equipment.

Newark element14 stocks Amphenol Industrial’s 97 Series general-duty standard circular connectors. Ideal for benign-environment applications in the automotive, robotics, machine tool, and welding industries, as well as for commercial applications ranging from heavy equipment to ECG monitoring cables, these versatile, multi-pin, mil-derivative connectors provide the lowest cost 5015-style solutions available. The series offers six shell options, including solid and split shell constructions, with metal threading, hard dielectric inserts, 128 contact arrangements, 1–52 non-rotating contacts, solder and crimp terminations, single key polarization, and accessories for both individual wire seal and jacketed cable. Shell components are fabricated from high-grade aluminum alloy to provide strength and environmental protection and are available with a wide variety of finishes, including gray zinc nickel and a conductive cadmium plate finish with an olive drab chromate after-treatment. The durable, field-proven series is rated for operating temperatures extending from -55°C to +125°C, is intermateable and intermountable with existing 97 Series and SAE AS50151 connectors, and is compliant with RoHS, UL, and CSA specifications. It and is also available with thermocouple arrangements and optional gold plating.

stocks Amphenol Industrial’s 97 Series general-duty standard circular connectors. Ideal for benign-environment applications in the automotive, robotics, machine tool, and welding industries, as well as for commercial applications ranging from heavy equipment to ECG monitoring cables, these versatile, multi-pin, mil-derivative connectors provide the lowest cost 5015-style solutions available. The series offers six shell options, including solid and split shell constructions, with metal threading, hard dielectric inserts, 128 contact arrangements, 1–52 non-rotating contacts, solder and crimp terminations, single key polarization, and accessories for both individual wire seal and jacketed cable. Shell components are fabricated from high-grade aluminum alloy to provide strength and environmental protection and are available with a wide variety of finishes, including gray zinc nickel and a conductive cadmium plate finish with an olive drab chromate after-treatment. The durable, field-proven series is rated for operating temperatures extending from -55°C to +125°C, is intermateable and intermountable with existing 97 Series and SAE AS50151 connectors, and is compliant with RoHS, UL, and CSA specifications. It and is also available with thermocouple arrangements and optional gold plating.

Omnetics Connector Corporation ’s Micro 360® Twist-Lock Circular Connectors are designed to maintain electrical integrity in high shock and vibration environments and are qualified to MIL-DTL-83513 01/02/03/04 specifications. They have panel-mount metal housings with straight through-hole terminations, IP68 seals, LCP insulators per MIL-M-24519, beryllium copper pins, copper alloy sockets, and either non-RoHS solder (per J-STD-006) or RoHS-compliant hard gold plate (per ASTM B488) PC tails. Additional options include five pin counts (5, 12, 16, 27, and 39) and four shell materials and finishes: nickel-plated brass, black-nickel-plated brass, passivated stainless steel, and black oxide finished steel. The series is rated for 3A per contact, 250VAC dielectric withstanding voltage at sea level, 50g shock and 20g vibration with no discontinuities for more than a microsecond, and operating temperatures extending from -55°C to 125°C (or up to 200°C with high-temperature epoxy).

’s Micro 360® Twist-Lock Circular Connectors are designed to maintain electrical integrity in high shock and vibration environments and are qualified to MIL-DTL-83513 01/02/03/04 specifications. They have panel-mount metal housings with straight through-hole terminations, IP68 seals, LCP insulators per MIL-M-24519, beryllium copper pins, copper alloy sockets, and either non-RoHS solder (per J-STD-006) or RoHS-compliant hard gold plate (per ASTM B488) PC tails. Additional options include five pin counts (5, 12, 16, 27, and 39) and four shell materials and finishes: nickel-plated brass, black-nickel-plated brass, passivated stainless steel, and black oxide finished steel. The series is rated for 3A per contact, 250VAC dielectric withstanding voltage at sea level, 50g shock and 20g vibration with no discontinuities for more than a microsecond, and operating temperatures extending from -55°C to 125°C (or up to 200°C with high-temperature epoxy).

Fischer Connectors ’ UltiMate™ Series connectors and cable assemblies are rugged, compact, lightweight, hermetically sealed, and sealed to IP68/IP69 even when unmated, providing high-reliability solutions for a wide variety of applications with severe environmental, industrial, chemical, and blind-mating conditions. The circular, push-pull connectors have excellent 360° EMC shielding, extremely robust keying, and a grounding contact ring, and exhibit robust resistance to shock, vibration, and corrosion. Rated for 10,000 mating cycles and temperatures extending from -55°C to +135°C, the series is available in a wide range of configurations, including cable- and panel-mounted plugs and receptacles with brass and aluminum shells, crimp and solder contacts, and optional sealing caps and color-coded overmolding. The smallest configuration in the series, the Fischer UltiMate 07, offers up to 10 contacts, and high-power solutions offer up to 26A.

’ UltiMate™ Series connectors and cable assemblies are rugged, compact, lightweight, hermetically sealed, and sealed to IP68/IP69 even when unmated, providing high-reliability solutions for a wide variety of applications with severe environmental, industrial, chemical, and blind-mating conditions. The circular, push-pull connectors have excellent 360° EMC shielding, extremely robust keying, and a grounding contact ring, and exhibit robust resistance to shock, vibration, and corrosion. Rated for 10,000 mating cycles and temperatures extending from -55°C to +135°C, the series is available in a wide range of configurations, including cable- and panel-mounted plugs and receptacles with brass and aluminum shells, crimp and solder contacts, and optional sealing caps and color-coded overmolding. The smallest configuration in the series, the Fischer UltiMate 07, offers up to 10 contacts, and high-power solutions offer up to 26A.

Kensington Electronics stocks Smiths Interconnect’s HyperGrip Series connectors. These circular, plastic, color-coded, push-pull connectors are user-keyable and -configurable and offer six different keying options with a set of common components to reduce cost, lead-time, and inventory. The series enables connector configurations with 5, 12, 19, or 33 Hypertac, spring probe, fiber optic, or coaxial contacts, in addition to EMI/RFI shielding, IP67 sealing, and five color coding options. Designed to meet medical industry requirements, such as finger-proofing to UL544 and IEC 60601-1, the series also features a unique front- or rear-panel-mount receptacle design that allows users to mount the harness assembly from the inside or outside of device enclosures. HyperGrip Series connectors are flammability rated to UL94 V-0 and compatible with most sterilization requirements, and are rated for 1A per contact, operating temperatures extending from -40°C to 125°C, and up to 20,000 mating cycles.

stocks Smiths Interconnect’s HyperGrip Series connectors. These circular, plastic, color-coded, push-pull connectors are user-keyable and -configurable and offer six different keying options with a set of common components to reduce cost, lead-time, and inventory. The series enables connector configurations with 5, 12, 19, or 33 Hypertac, spring probe, fiber optic, or coaxial contacts, in addition to EMI/RFI shielding, IP67 sealing, and five color coding options. Designed to meet medical industry requirements, such as finger-proofing to UL544 and IEC 60601-1, the series also features a unique front- or rear-panel-mount receptacle design that allows users to mount the harness assembly from the inside or outside of device enclosures. HyperGrip Series connectors are flammability rated to UL94 V-0 and compatible with most sterilization requirements, and are rated for 1A per contact, operating temperatures extending from -40°C to 125°C, and up to 20,000 mating cycles.

AirBorn ’s Series 360® circular interconnect system is small, lightweight, watertight, extremely rugged, reliable, and easy to clean. Designed as a smaller, lighter alternative to ubiquitous 38999 connectors, the series has a sleek geometry that enables easy I/O cable connectivity in a wide range of harsh-environment military and defense applications, including communications systems, navigation modules, soldier control units, radar, avionics equipment, embedded computers, GPS antennas, handheld devices, rugged computers, night-vision equipment, unmanned systems, and land vehicles. The series offers excellent EMI shielding, a push-pull locking mechanism, Quick-DeMate® functionality, optimized mechanical and color keying, IP68 and IP69 protection, and robust resistance against shock and vibration. Configurations include board- and panel-mount connectors, cable assemblies, and flex-circuit assemblies with 3–55 contacts, solder cup and plated-through-hole terminations, and ruggedized plastic and metal shells, as well as Quick-Clean® and high-speed versions up to 10Gb/s.

’s Series 360® circular interconnect system is small, lightweight, watertight, extremely rugged, reliable, and easy to clean. Designed as a smaller, lighter alternative to ubiquitous 38999 connectors, the series has a sleek geometry that enables easy I/O cable connectivity in a wide range of harsh-environment military and defense applications, including communications systems, navigation modules, soldier control units, radar, avionics equipment, embedded computers, GPS antennas, handheld devices, rugged computers, night-vision equipment, unmanned systems, and land vehicles. The series offers excellent EMI shielding, a push-pull locking mechanism, Quick-DeMate® functionality, optimized mechanical and color keying, IP68 and IP69 protection, and robust resistance against shock and vibration. Configurations include board- and panel-mount connectors, cable assemblies, and flex-circuit assemblies with 3–55 contacts, solder cup and plated-through-hole terminations, and ruggedized plastic and metal shells, as well as Quick-Clean® and high-speed versions up to 10Gb/s.

ODU MINI-SNAP® circular push-pull connectors with pin-and-groove coding reliably transmit power, signal, data, or media in medical, industrial, test and measurement, military, security, energy, and e-mobility applications and are rated for 5,000 mating cycles. They have robust metal housings with IP50 or IP68 sealing and a high-reliability push-pull locking mechanism that cannot be released by pulling on the cable, but can easily be unmated from the receptacle when the outer sleeve is pulled back. The range is available in L, K, and B Series variants with a wide range of contact inserts and 2–40 contacts. Additional options include six sizes, a multitude of plugs and receptacles, and solder, crimp, or PCB terminations.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation

- May 2021 New Connectivity Products - May 4, 2021

- Off-Highway Equipment Connectors Product Roundup - May 4, 2021

- Blind-Mating Coaxial Connectors Product Roundup - April 20, 2021