MIPI A-PHY Automotive Interface Helps Integrate Advanced Connectivity

As automotive applications expand to include complex sensor, camera, and infotainment capabilities, a more powerful, design-friendly connectivity specification will help manage the required power and data.

As the connected car continues to evolve, essential operational systems are being augmented with new capabilities, such as autonomous functions, driver-assist technologies, advanced safety features, and infotainment systems. Electrification trends further add to the technology requirements in vehicles. In coming years, vehicles will be able to interface with smart city infrastructure, increasing connectivity within and outside of the vehicle. These trends have increased vehicular demand for power, signal, and high-speed connectivity, leading to increasingly complex and bulky wiring strategies. Efforts are underway across the automotive and electronics industry to facilitate the design of more powerful, lightweight, and streamlined cabling and connectivity designs. A powerful new tool to achieve these goals is MIPI A-PHY v1.0, a long-reach serializer-deserializer (SerDes) physical layer interface for automotive applications.

Connected vehicles will benefit significantly from the new MIPI A-PHY interface.

By 2024, the first generation of cars equipped with MIPI A-PHY is expected to be in production. This specification will enable designers to deliver point-to-point topology with high-speed unidirectional data, embedded bidirectional control data, and optional power delivery — all over a single cable. It will reduce wiring cost, bulk, and weight; deliver high-speed data, control data, and power using the same wiring; and will allow designers to optimize sensor applications, cameras, and displays.

MIPI A-PHY is in the final approval phase with the MIPI Alliance, a global consortium that includes a broad membership of technology companies, automobile manufacturers, and electronics suppliers, including Apple, Tesla, Advanced Micro Devices (AMD), Hirose Electric, and JAE. We talked to the MIPI Alliance to learn more about this specification.

Why was a separate SerDes specification needed for automotive applications?

As automotive technology continues to evolve, the need for new interfaces that offer high performance at a low cost and with less complexity become even more imperative. The age of hyper-aware vehicles is just beginning and MIPI A-PHY, the forthcoming long-reach SerDes automotive physical layer specification, offers the interface needed to meet these challenges. In addition, today’s automotive designs rely on SerDes chipsets for long-reach interconnects between both sensors and processors and displays and processors. These chipsets lack standards-based economies of scale. That’s where MIPI A-PHY comes in. The unique capabilities of A-PHY will make this specification an ideal long-reach interface to help manufacturers and suppliers more quickly integrate the components of advanced driver-assistance systems (ADAS), autonomous driving systems (ADS), and in-vehicle infotainment systems (IVI) in upcoming vehicles.

Tell me about the cable that is used with this specification.

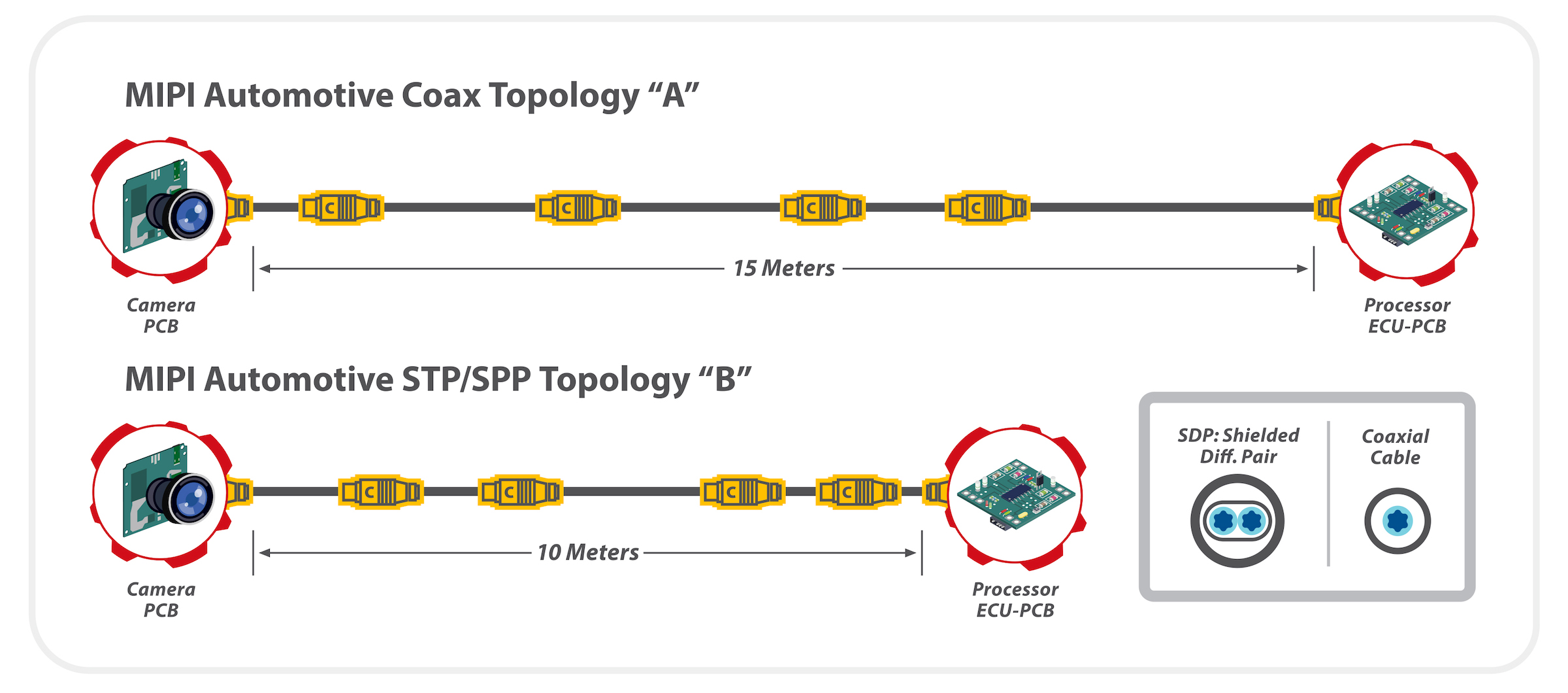

MIPI A-PHY will support both coaxial cables up to 15m and shielded differential pair (SDP) cables up to 10m, each with up to four inline connectors and a minimum segment of 30cm.

MIPI A-PHY supports both coaxial cables and shielded differential pair (SDP) cables

What can you share about the physical properties and design features of the specification?

The majority of high-speed links in the car derive from sensors, cameras, and displays. These links have unique characteristics, as they are highly asymmetric, and require efficient design to support small-size, low- cost, and low-power sensors. A simplified, efficient, and optimized architecture is a must.

A-PHY offers efficient point-to-point topology with high-speed unidirectional data, embedded bidirectional control data, and optional power delivery over a single cable. It reduces wire harness complexity and weight, supports multi-streaming and daisy-chain topology, and eliminates software overhead and complexity.

Its key features include:

- Long reach: up to 15m

- High performance: five speed gears (2, 4, 8, 12, and 16Gb/s), with a roadmap to 48Gb/s and beyond

- High reliability: ultra-low packet error rate (PER) of 10-19 for unprecedented performance over the lifetime of a vehicle

- High resilience: ultra-high immunity to EMC effects by virtue of a unique PHY- layer retransmission system

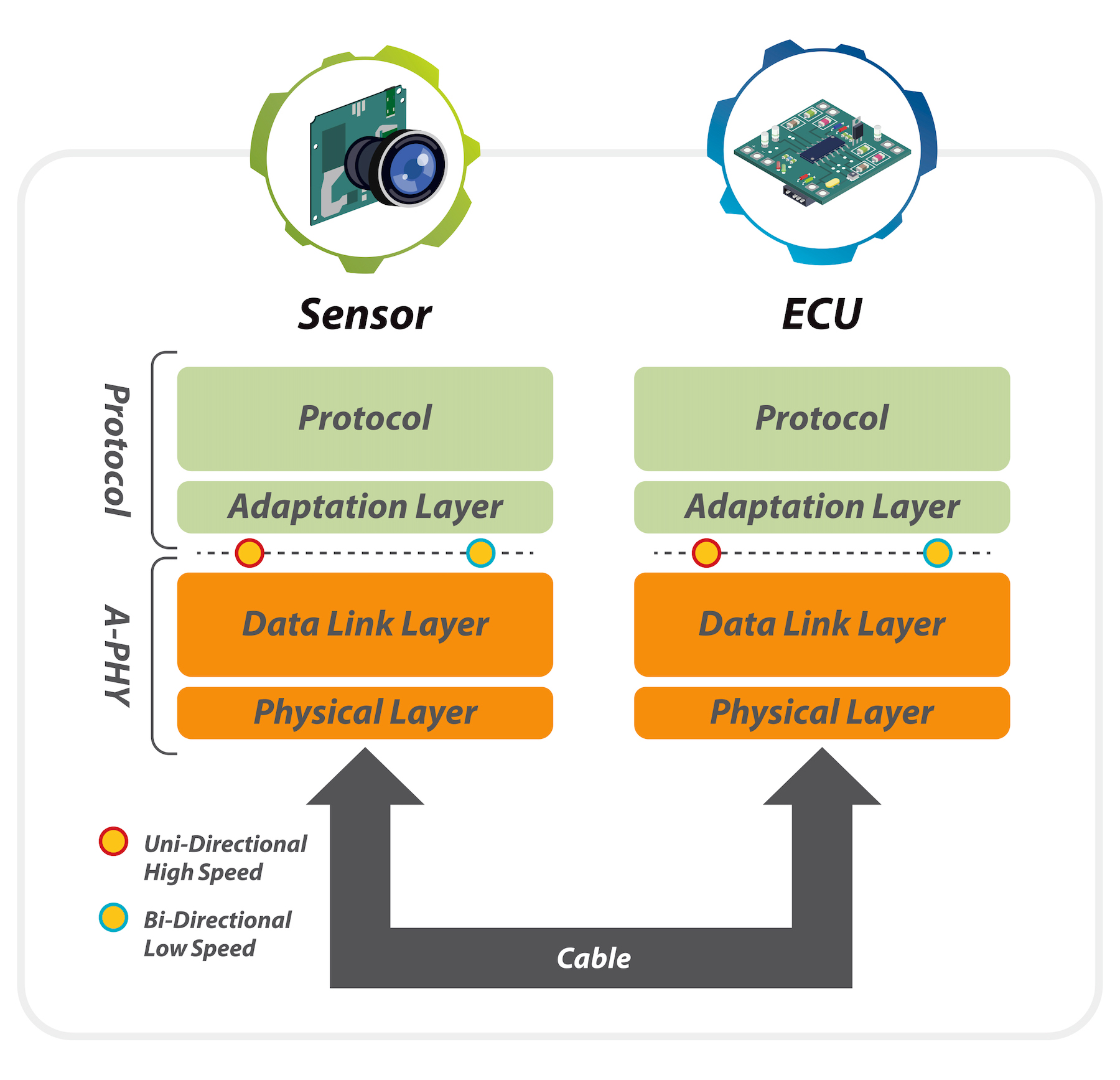

MIPI A-PHY high-level structure

What features enable it to operate in harsh automotive environments?

Sensor links are particularly susceptible to electromagnetic interference, data loss, and latency as link bandwidth and distance increase. As such, there is a need for a standard that meets stringent EMC requirements and offers stricter testing to guarantee proper performance and high resilience.

A-PHY offers extraordinary reliability and resiliency with a PER 10-19 equivalent to one error per 10,000 car lifetimes and high EMI immunity for up to 15m using a narrow-band interference canceler (NBIC) and a PHY-level retransmission system (RTS) to reduce the occurrence of errors and rapidly recover with a retransmission when required.

How does this spec relate to VESA’s upcoming DisplayPort update?

MIPI Alliance is working closely with VESA in the development of an A-PHY adaptation layer for use with its DisplayPort and Embedded DisplayPort standards. MIPI’s collaboration with VESA will ensure that next-generation IVI and other multiple displays in the car are well-served with DP/eDP protocols over A-PHY.

What kind of impact will this spec have on the other systems in the vehicle that it supports?

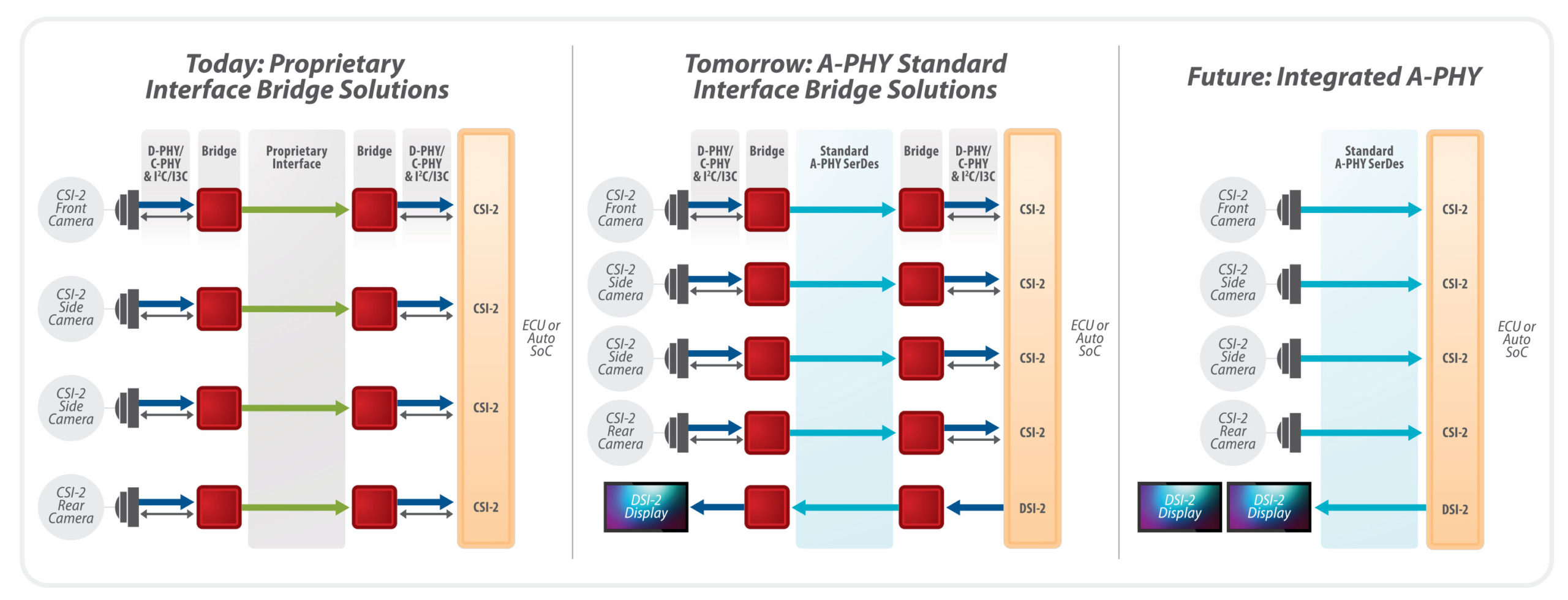

MIPI A-PHY serves as the foundation of what will be an end-to-end system designed to simplify the integration of cameras, sensors, and displays, while also incorporating functional safety and security. Higher-layer MIPI protocols, such as Camera Serial Interface (MIPI CSI-2) and Display Serial Interface (MIPI DSI-2), are already used to connect sensors and displays to domain ECUs and other onboard computers in many vehicles. They are currently transported over MIPI C-PHY or D-PHY shorter-reach physical layers and use bridge solutions to connect to proprietary long-reach PHYs. With the use of upcoming MIPI adaptation layers, these higher-layer protocols will run natively over A-PHY, eliminating the need for these proprietary bridges.

MIPI A-PHY will simplify the integration of cameras, sensors, and displays

Will its capability become a starting point for further innovations, such as in sensors or cameras?

Yes, in conjunction with the development of A-PHY, new versions of MIPI’s camera and display specifications are also underway. These new versions are designed to not only work with A-PHY but will also provide new features and capabilities as well. As mentioned earlier, development is also being done to bring in critical functional safety and security features, too.

Like this article? Check out our other Sensors, Standards, and Cable articles, our Wire and Cable Assemblies and Automotive Market Pages, and our 2020 and 2019 Article Archives.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024