Sensor Technologies Depend on Special Sensor Cables

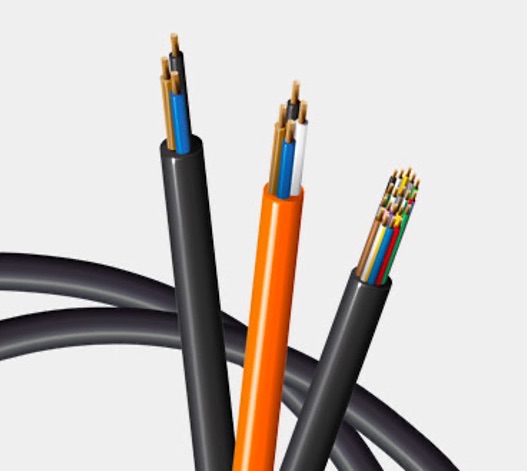

Although often taken for granted, cable is a critical enabling technology. As connected and smart devices multiply, so does the need for the specialized cables that connect the many types of sensors needed to enable smart and autonomous applications across a broad spectrum of industries.

Cables that connect sensors are designed to optimize the performance and delivery of electrical signal and data transmissions. Sensors detect stimuli in the form of heat, light, sound, motion, gas, liquid or other physical properties, convert that information into electrical signals, and send that data to a control device or instrument over specialized sensor cables. There are many types of sensors, including temperature sensors, infrared (IR) sensors, fluidic/flow control sensors, ultrasonic sensors, piezoelectric accelerometers, pressure sensors, moisture/humidity sensors, photo-optic sensors, proximity sensors, vibration, and touch sensors.

A Senix ToughSonic 14 Ulrasonic Sensor cable assembly. (Image by Bpducharme, republished per CC BY-SA 4.0).

Sensors, connectors, and cables that operate in demanding applications, like many of those within the military and aerospace market, must meet rigorous performance requirements, quality standards, and survive harsh environments. In these markets, small, lightweight connectivity products are required to help reduce overall system bulk and payload, and materials must be carefully selected to minimize off-gassing. Applications in the industrial, transportation, automotive, and medical markets can also place additional demands on sensors, sensor cables, and connectors.

The sensor market is expected to reach $287 billion with a CAGR of 9.5% by 2026, up from $166 billion in 2019. Many electronics suppliers that offer cable are now integrating sensors and connectors to offer specialized sensor cable assemblies optimized to serve environments and applications in every market. The applications and environments where sensor cables are used vary widely, making appropriate cable specification a critical design consideration.

Safe, Effective, and Environmentally Friendly Sensor Cables

Sensor cables from SAB, available from Allied Electronics and Automation, Digi-Key Electronics, and Newark, an Avnet company, have been developed with a strong focus on material science and process technology. These cables are used in industrial sectors that depend on electronic measurement, control, and automation.

SAB Besilen sensor cables are encapsulated in silicone and can withstand temperatures from +180°C to +250°C due to the reticulated molecular structure that maintains their original form even when exposed to high temperatures. These cables are halogen-free, heat-resistant, flame-retardant, self-extinguishing, and highly flexible. Besilen sensor cables are often used with position sensors in industrial and commercial oven applications in low-pressure carburizing processes, steel works, mills, and foundries, as well as in furnaces, in the internal wiring of lamps, and in glass and ceramic production equipment.

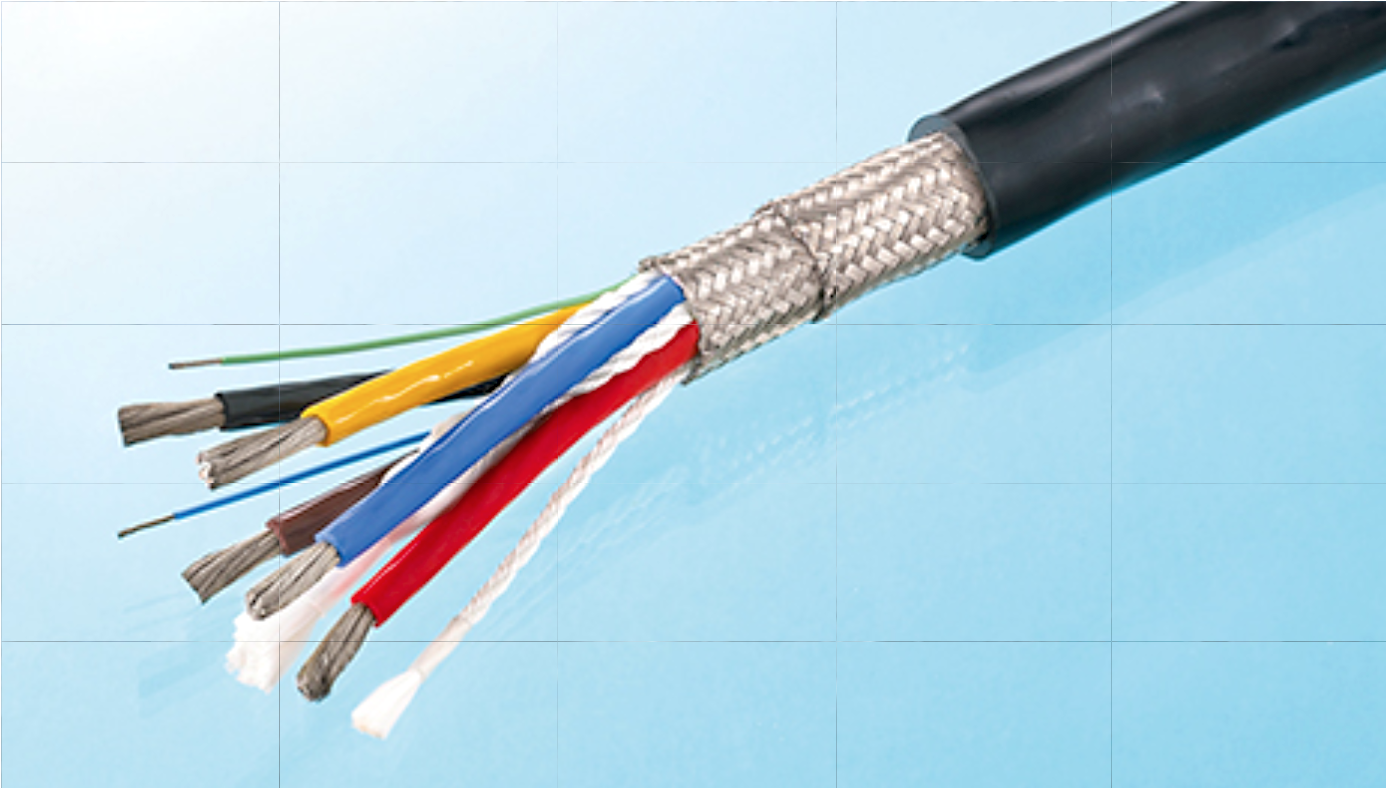

SAB also offers sensor cables made with ETFE, FEP, and PFA encapsulation. These materials feature insulation that enables them to withstand extremely harsh environments and temperatures ranging from -90°C to +260°C. ETFE-, FEP-, and PFA-insulated cables also resist many chemical influences while maintaining high mechanical resistance and are widely employed in applications including the chemical production, furnace construction, and telecommunications infrastructure.

SAB SABIX halogen-free cables are ideal for public buildings and institutions, railway vehicles, and other applications with very high safety requirements. They are flame-retardant, self-extinguishing, and fully recyclable.

Belden’s sensor/actuator cables feature high flexibility, durability in tough environments, low data rates, and small outer diameter tolerances for sealing.

Belden Sensor/Actuator Cables, available through Allied Electronics & Automation, Arrow Electronics, and Newark, an Avnet Company, are analog signal cables that connect automation sensor systems to devices in rugged industrial environments. These cables serve demanding applications in food and beverage production, machine building, automotive, material handling, industrial robotics, automation, and instrumentation applications. With over 110 years of cabling experience, Belden delivers high levels of quality in centricity (roundness), consistent strip-ability, and jacket thickness, and continues to miniaturize cable outside diameters while increasing its range of special sensor connecting cables.

Minnesota Wire and Cable has conductive cabling that stretches 40% while maintaining optimal electronic performance. iSTRETCH unshielded cable is available as a six-conductor, 26-gauge construction with polyurethane jacket, or as a shielded cable with 44AWG serve shield that promotes signal integrity. These cables can be used in medical, sports, military, defense, and aerospace applications including body-worn vests that monitor body function and support robust connectivity, such as soldier-worn and first responder systems.

Sensor Cables Serve Electric, Hybrid, and Autonomous Vehicles

Both automotive and non-automotive modes of transportation, such as motorcycles and e-bikes, rely on sensor technologies to expand e-mobility features and capabilities including advanced driver-assist and autonomous driving features, electrification, and vehicle-to-vehicle (V2V) and vehicle-to-everything (V2X) communication. A wide range of sensors, including radar, LiDAR, oxygen, proximity, pressure, ultrasonic, rain, temperature, current, and speed sensors are needed to maintain vehicle operations, as well as fueling, parking, driving, and other functions.

Amphenol Industrial Operations offers a signal splitter featuring six terminal inputs that allow for higher combinations of functions in a single connector. The Tru-Loc Splitter helps to reduce the number of connectors needed in an application and is suitable for use in automotive and industrial sensor applications.

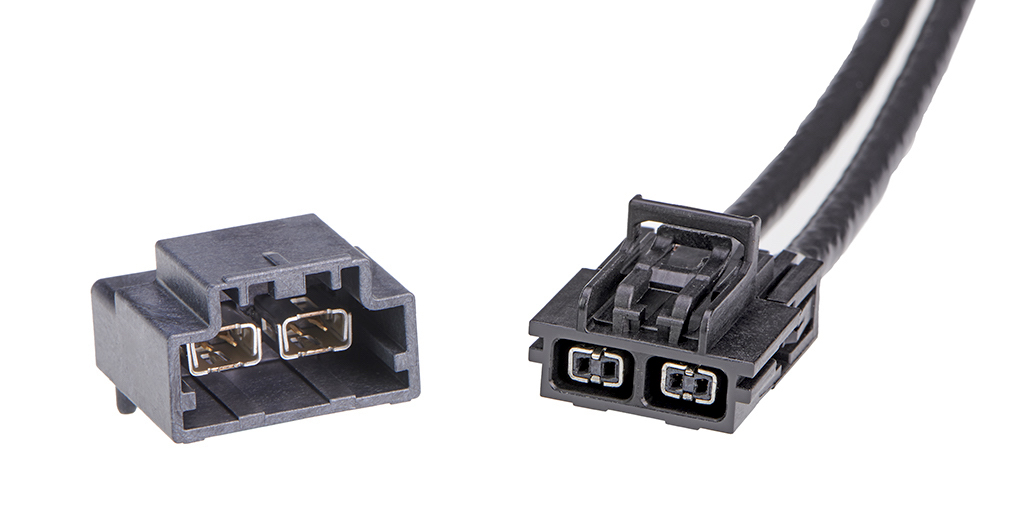

TE Connectivity offers custom sensor cables (left) designed to survive in oil-contaminated, high-temperature vehicle environments, where they are exposed to abrasion and constant flexing. Options include operating temperate range, jacket diameter, and choice of conductors, screens, and jacket materials.

Molex’s HSAutoGig automotive Ethernet cable solution (below) supports high-speed cables, sensors, cameras, gateways, and switches used for autonomous vehicles. A solid 360° shield around the signal pair contacts protects data from outside noise, EMI/EMC or signal degradation.

Axon’ Cable offers high-resistance cable (below) designed to endure flexing, torsion, abrasion, and high temperatures in harsh automotive environments. These connector and sensor cables feature specialized insulation materials that are chemically inert to provide rugged resistance to engine fluids and high temperatures. Axon’ Cable is also able to manufacture thermocouple cables and cables for Rogowski sensors, integrate sensors with a connector, or create sensor cables for use in a mechanical system.

Axon’ Cable offers high-resistance cable (below) designed to endure flexing, torsion, abrasion, and high temperatures in harsh automotive environments. These connector and sensor cables feature specialized insulation materials that are chemically inert to provide rugged resistance to engine fluids and high temperatures. Axon’ Cable is also able to manufacture thermocouple cables and cables for Rogowski sensors, integrate sensors with a connector, or create sensor cables for use in a mechanical system.

Medical Imaging Devices Demand Miniaturized Sensor Cables

Sensors enable medical devices to detect physical, chemical, and biological signals and provide a way for those signals to be measured and recorded. They can be used to measure pressure, fluid levels, temperature, pulse, heart rate, and other vital signs, or to detect and convey information used to make X-ray, ultrasound, and endoscopic images. These types of sensors all depend on miniaturized cables that can fit inside small, lightweight, and portable devices.

Sensors enable medical devices to detect physical, chemical, and biological signals and provide a way for those signals to be measured and recorded. They can be used to measure pressure, fluid levels, temperature, pulse, heart rate, and other vital signs, or to detect and convey information used to make X-ray, ultrasound, and endoscopic images. These types of sensors all depend on miniaturized cables that can fit inside small, lightweight, and portable devices.

Fujikura Imaging Sensor Cables, for instance, (pictured here) have a tiny 0.9mm cable diameter and integrate complementary metal-oxide-semiconductor (CMOS) image sensors, which allows them to be used in numerous reusable and disposable medical devices, such as endoscopes.

Agricultural Cables Withstand Harsh Environments

Leoni Sensor Cables, pictured below (left) and available through Arrow Electronics, have been especially developed to support the real-time remote monitoring of water supplies to ensure healthy crops. To meet the requirements for this special request, Leoni developed a flexible, miniature, lightweight, 1.4mm-diameter shielded sensor cable that is resistant to chemical fertilizers and UV rays and can withstand temperature fluctuations and moisture ingress.

Newark, an Avnet company, offers Banner Engineering Corporation’s MQDC1-506 sensor cables (above right). These Euro-style, quick-disconnect cables are designed for use with mini-beam expert sensors and have a chrome-plated brass coupling nut that allows sensors and safety devices to be connected, disconnected, or replaced quickly and easily while in the field. They can also support DC-powered devices and has an IP67 moisture ingress rating.

Phoenix Contact provides passive field cabling solutions equipped with M5 to M12 connectors (above) for the connection of sensors and actuators in harsh-environment industrial, food and beverage, construction equipment, railway infrastructure, robotic, and outdoor equipment applications. Multi-position connectors, coupled with cabling solutions, provide pluggable sensor-to-actuator cabling for M12 distribution boxes and enable easy installation and service in the field. Phoenix Contact M12 cables for signal, data, and power are designed for ease of use and are available with various cabling termination methodologies, including insulation displacement, crimp, screw-in, and push-in spring connections.

Siemon Interconnect Solutions’ M12 D-Coded Cable Assemblies for industrial Ethernet and PROFINET networks provide compact, robust, and reliable connections in harsh-environment applications including industrial automation equipment and switch, sensor, and control systems. The robust 26AWG cordsets combine a specially designed polyurethane (PUR) cable jacket with 360° shielding and an overmolded connector to provide IP67 ingress protection and protection from other common industrial elements, including EMI, chemicals, UV radiation, shock, vibration, and other mechanical stress.

Cable Solutions for Renewable Energies

With worldwide concerns about climate change increasing, the installation of wind turbines continues to grow. Wind turbines that convert mechanical energy into safe, effective, reliable, and renewable green energy use many sensors. Although wind turbines are quite large, with rotors 79m long and towers more 183m high, small sensors measuring only centimeters in length play a critical role in these installations, which face continual stress, vibration, temperature fluctuations, and other environmental and operational challenges. Mouser Electronics offers Eddy current sensors (also called Foucault currents) that detect changes in electrical current, displacement sensors that are used to monitor structural integrity, accelerometers that measure changes in velocity, speed, and vibration, ultrasonic wind sensors that measure the distance to an object by using sound waves, and temperature sensors that use thin film resistors as the sensing element to detect temperature increases that may indicate overheating.