What are Micro-D connectors?

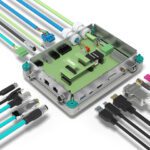

Meet the Connector: Micro-D Connector The tiny but mighty micro-D connector is half the size of a standard D-sub yet delivers rugged and reliable performance in commercial and military applications. Micro-D (and nano-D) connectors were derived from D-sub (D-subminiature) connectors in the 1970s. Their compact design led to their early popularity for use in computers.Read More