Selecting Test Probe Tips to Test Printed Circuit Boards

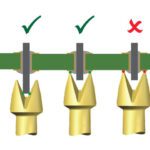

In-circuit and post-manufacture functional testing are critical steps to ensuring PCB dependability. Test probes provide the flexibility to make the electrical connections between the test system and the contact points on the PCB. Learn how to select the correct one for your process. Many factors affect a test probe’s ability to make reliable electrical contact.Read More