The Internet of Battlefield Things is Changing Connector Designs

Interconnects directly contribute to the size, weight, reliability, ruggedness, and overall performance of modern military equipment, which is increasingly interconnected via the Internet of Battlefield Things or IoBT.

As Admiral John Richardson, Chief of Naval Operations, put it during the Navy’s Future Force Expo in Washington, DC, in 2017, “I’d want to network everything to everything.” At that point, the Internet of Things (IoT), which essentially aims to do just that, had already expanded into markets ranging from industrial to consumer, medical, and even military electronics. Military applications, although often similar to their commercial counterparts, have much more serious security risks and are often subjected to much harsher environmental conditions, including intense shock and vibration, extreme temperatures, rough handling, pressure changes, and exposure to dust, dirt, water, weather, and chemicals. Internet of Battlefield Things

To leverage the benefits of the IoT, the military created its own version, governed by the stringent security measures and rigorous electrical and mechanical requirements it employs to ensure soldier safety and mission success. The Internet of Battlefield Things (IoBT) is an actively expanding network of sensors, wearables, and other IoT devices that use cloud and edge computing to create a cohesive fighting force.

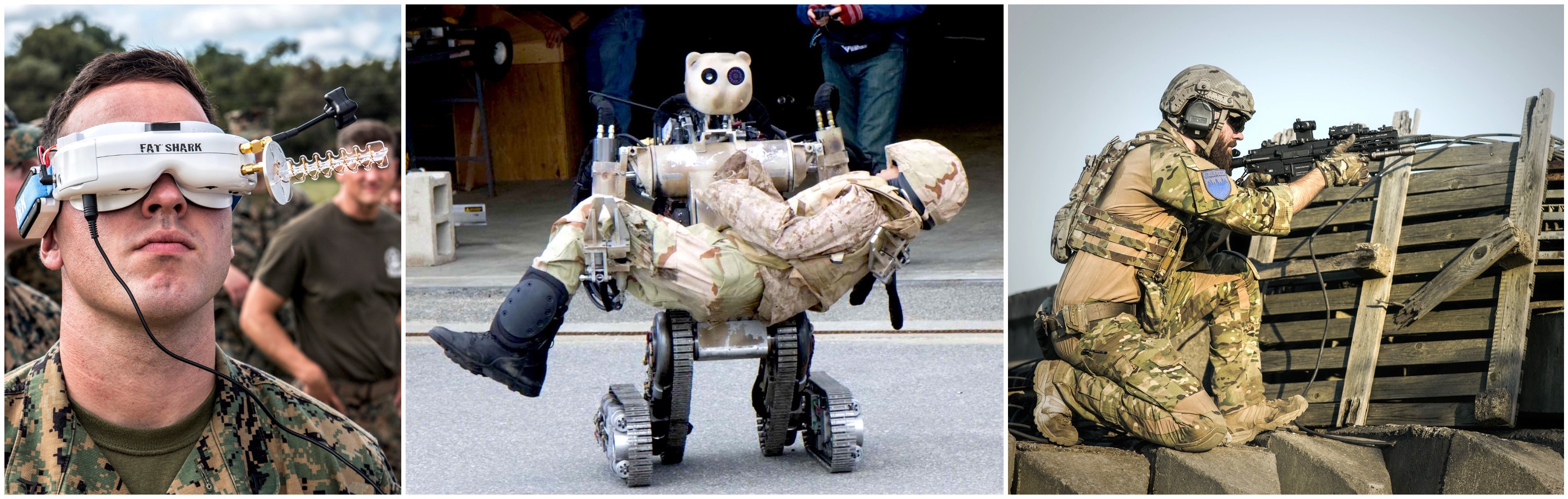

The IoBT is a rapidly expanding network of innovative technologies designed for soldier support, including drone-view headsets (left), Battlefield Extraction Assist Robots (center), and wearable-enabled tactical vests and helmets (right).

One key point on the IoBT expansion map is wearables. In addition to significantly expanding digital connectivity capabilities, wearables could hold the key to reducing casualty rates by enabling the rapid detection, triage, and clinical management of wounded soldiers on the battlefield. Body-worn biosensors can already detect and transmit soldier statistics like heart rate and hydration. When paired with innovative monitoring technology like the Compensatory Reserve Index (CRI), which can quantify a failing cardiac system due to the reduction of blood in a vessel or vessels based on photoplethysmography (PPG) measurements, sensors can accurately detect and transmit information about hemorrhages and other critical problems. According to an article in the December 2012 issue of Military Medicine, 81.5% of casualties analyzed between 2002 and 2009 resulted in death due to hemorrhage. Wearables capable of detecting hemorrhages, accurately assessing their severity, and rapidly alerting the base and medics could be of crucial importance. The key to success will be speed of detection, communication, and ultimately, care.

However, adding systems to overburdened dismounted soldiers poses its own problem. In 2016, the Marine Corps Times reported that infantry officers are expected to carry up to 152 pounds for 9.3 miles at a three-mile-per-hour pace, which many people argue is already unrealistic. So military device designers and interconnect manufacturers are developing solutions that will give soldiers new technologies like IoBT wearables to improve connectivity, mission success, and safety without further increasing pack weights.

The Fischer Freedom™ Series LP360™ connector was especially designed for harsh-environment body-worn applications.

Fischer Connectors is among several connector and cable manufacturers working to add capabilities while minimizing size and weight. Its Fischer Freedom Series LP360 connector is a rugged but lightweight connector with 360° mating freedom that delivers breakthrough plug-and-play connectivity and is easy to integrate into portable and body-worn applications. Designed with soldiers, police, firefighters, and other first responders in mind, it reduces cognitive, weight, and reliability burdens, offers effortless, intuitive mating, provides IP68 protection when mated, and enables quick and easy plug and receptacle cleaning to help ensure 10,000-cycle durability. Its compact, lightweight, and low-profile design enables easy wearable integration, panel-mounted cable assemblies, and direct device integration with minimal cabling. It is compatible with USB 2.0 and Ethernet protocols.

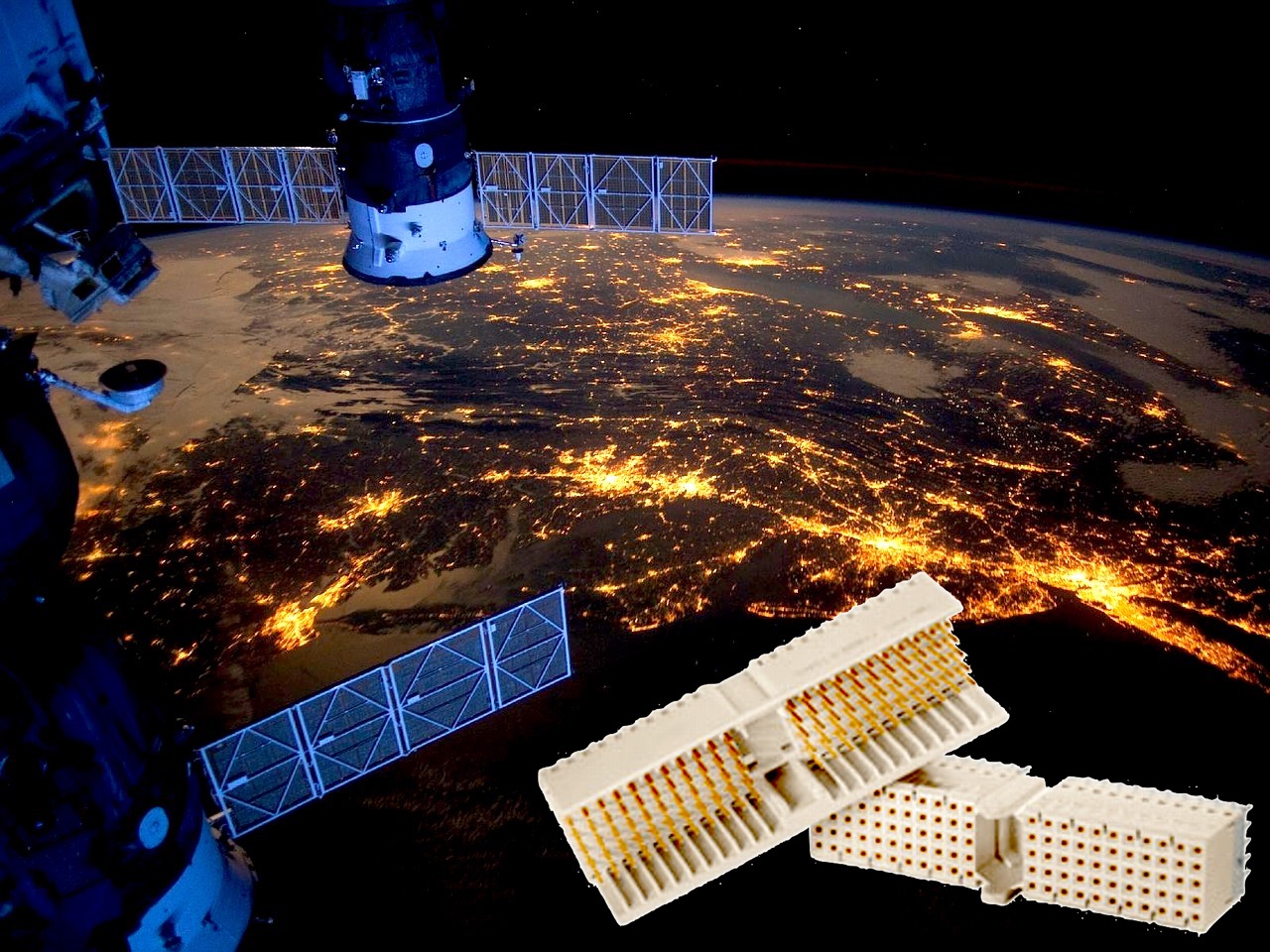

Another critical point in the IoBT system is broadband internet service with consistent coverage. Military personnel frequently operate in harsh environment areas with spotty remote signal coverage. In these instances, IoBT connectivity is best maintained using low earth orbit (LEO) satellites, which can be deployed anywhere around the globe and even arranged into constellations to provide high-strength, high-reliability broadband signals. In 2017, DARPA announced its Blackjack project, the goal of which is to develop a LEO constellation dedicated to providing constant coverage for military operations. This would help provide crucial support for IoBT devices employed in remote areas (e.g., deserts, oceans, and dense forests) and extreme topography where they are unable to establish direct terrestrial network accesses and, in doing so, provide crucial support for multitudes of special missions. LEO satellite constellations can operate at relatively low altitudes and move much faster than traditional geosynchronous equatorial orbit (GEO) satellites.

Smiths Interconnect’s SpaceNXT Aurora Series Hard Metric Connectors are qualified and tested to the ESA ESCC 3401 standard, which makes LEO design-in both quicker and more cost effective.

Like soldier-worn applications, LEO satellites also require components that contribute to significant space and weight reductions, as it costs about $10,000 to put one pound of payload into Earth’s orbit. Smiths Interconnect’s SpaceNXT Aurora Series is the first COTS-Plus 2mm hard metric backplane connector on the market that is qualified and tested to the European Space Agency’s (ESA’s) European Space Components Coordination (ESCC) 3401 standard. Designed with LEO satellites in mind, it not only addresses this market’s space and weight requirements but is designed to help customers reduce their lead-times, lower their total cost of ownership, and help ensure that end products meet all flight requirements without having to fund their own extensive component qualification process.

Drones are a crucial component of the IoBT and rely on a wide variety of high-reliability, high-speed, and harsh-environment connectors and cable assemblies to complete their missions.

Lastly, any discussion of IoT and IoBT applications should include drones. Unmanned aerial vehicles (UAVs) have been used by militaries around the world for a number of years and are a major microcosm of the IoBT. In February 2018, the United States Army Research Lab awarded $25 million to the Alliance for Internet of Battlefield Things Research on Evolving Intelligent Goal-driven Networks (IoBT REIGN) to develop new predictive battlefield analytics. In September 2018, Asteria Aerospace, a leading manufacturer of surveillance and security drones in India, announced the launch of Genesis, an industrial IoT network platform for drones that makes it possible to deploy multiple drones over large areas (e.g., many city blocks or more) and to route the live video feed from all the drones to a central command center. Decisions made at the command center can then be relayed to drone operators or quick response teams using the same platform to ensure that everyone has the exact same perspective of the operation.

Now that IoBT technology is proliferating, it’s also important to have ruggedly sealed high-speed, and high-reliability cable assemblies capable of transmitting data in outdoor and other harsh environments. Ethernet connectors are another important technology for IoBT applications and can support in-field military computing applications, including the processing of drone-derived data. One such solution is Stewart Connector’s Series RJ45TV D38999 connectors, which are designed to provide Ethernet connectivity in harsh environments. The series features rugged D38999-based shells, but with a unique design that reduces the footprint to the market’s smallest, size 17. It also employs high-performance RJ45 connections that reliably transmit 1G Base-T Ethernet, IP68 sealing, EMI protection, and four keyways to ensure proper mating in challenging conditions. It is rated for a minimum of 500-cycle durability and is available in multiple shell and plating materials.

Stewart Connector’s Harsh-Environment Series RJFTV 38999 Connectors are ideal for remote outdoor Ethernet applications, like in-field military computing.

The IoBT moves technology that was initially designed for use in controlled environments into harsher and less predictable environments. IoBT applications such as wearables, satellites, and drones must deliver consistent, reliable operation in a wide variety of harsh environments where they may be subjected to hazards, including intense shock and vibration, extreme temperatures, rough handling, pressure changes, and exposure to dust, dirt, water, weather, and chemicals. To effectively withstand these conditions, IoBT electronics must be extremely robust. A malfunction could result in mission failure, costly repairs or replacements, and even risk to human lives.

Visit Kensington Electronics, Inc. online. Internet of Battlefield Things

Like this article? Check out our other New Technology, IoT, and 2019 articles and our Military & Aerospace Market Page.

- Automotive Connectors Meet New Challenges as Vehicle Technologies Improve - September 22, 2020

- The Internet of Battlefield Things is Changing Connector Designs - September 17, 2019