Tiny Interconnect Products Bring Sound to Life – Cochlear Implant Connectors

A new generation of micro-sized electronics is helping hearing-impaired people connect with the world.

By Bob Stanton, Director of Technology, Omnetics Connector Corporation

Cochlear Implant Connectors

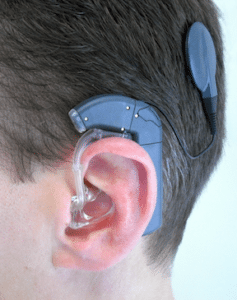

The cochlear implant, one of the most dramatic and effective treatments for hearing impairments and loss, has been around since 1957. In its earliest version, the device consisted of a simple six-channel electrode implanted in a patient’s ear. In the late 1970s, the first patients received an early version of the multi-unit system in use today. Since then, the design has evolved dramatically. Today’s implant is a complex system comprised of an external microphone that picks up sound from the environment, a speech processor that filters out ambient noise and focuses on audible communications, a transmitter that conveys sounds to an internal device via radio transmission, a receiver that transforms these sounds into electrical impulses, and an electrode array that is embedded inside the patient’s cochlea during a surgical procedure.

A MED-EL cochlear implant. Left: The implant with the receiver coil and the electrodes that are inserted into the cochlea. Center: The microphone, speech processor, and transmitter coil. Right: A remote control that adjusts signal processing. Image by Thomas Haslwanter, CC BY-SA 4.0, Wikimedia Commons: https://ow.ly/7ftu30lATFo.

Thanks to this device, hundreds of thousands of hearing-impaired people around the world can now hear. In addition, an aging global population, rising access to advanced medicine, and broad acceptance of this treatment by the hearing-impaired community mean that the market for cochlear implants is rapidly expanding. Several companies, including the pioneer Cochlear Limited, Advanced Bionics, and MED-EL, provide cochlear devices as well as non-implantable products that alleviate varying degrees of hearing loss.

Advanced electronic components provide critical support for the rapid evolution of the assisted hearing industry. Medical device manufacturers are continually refining the design to bring smaller, lighter, more sensitive, and more affordable units to the market. Micro-sized connectors and fine wire interconnect cable are two elements that are enabling recent improvements.

How it Works

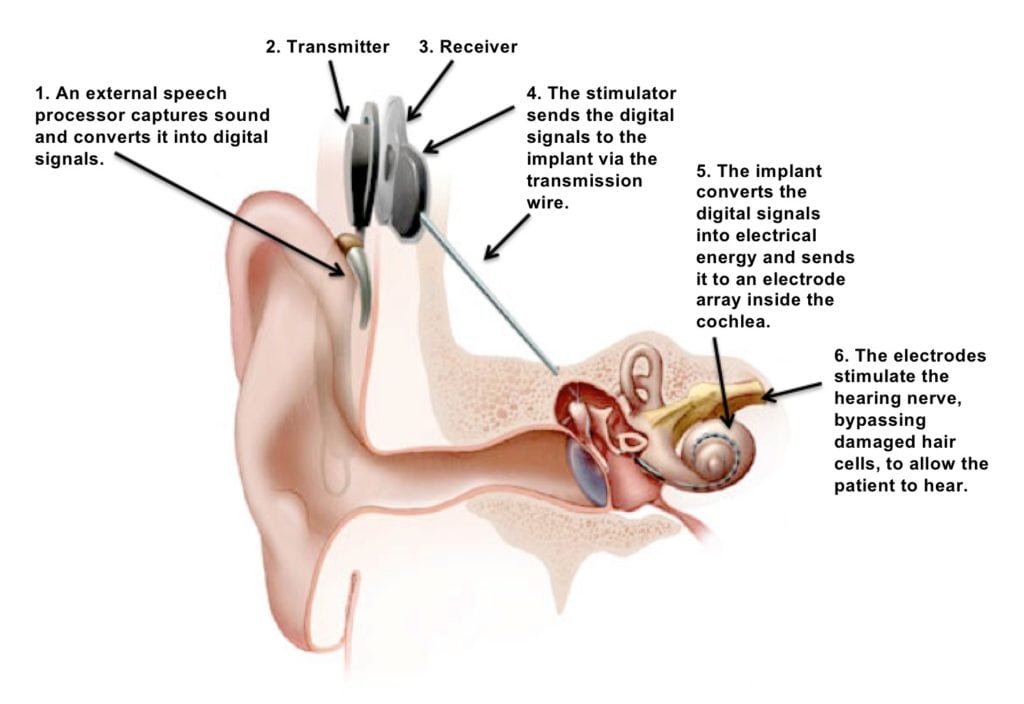

Sound waves pulse through the air and are received into the ear through a three-step process. The outer ear is a collector and tubular router for channeling sound into the middle ear. Our ear drum and its implements resonate and transfer tuned audio vibrations to the inner ear. Hearing losses within these two sections are often called conductive hearing loss. This kind of loss is often caused by simple issues like an ear infection or a hole in the ear drum. Sound is processed in the inner ear, where we have key apparatus such as the cochlea and auditory nerve and begin to add more intelligence and understanding to the sound as it is passed onto the hearing nerve.

Sound waves pulse through the air and are received into the ear through a three-step process. The outer ear is a collector and tubular router for channeling sound into the middle ear. Our ear drum and its implements resonate and transfer tuned audio vibrations to the inner ear. Hearing losses within these two sections are often called conductive hearing loss. This kind of loss is often caused by simple issues like an ear infection or a hole in the ear drum. Sound is processed in the inner ear, where we have key apparatus such as the cochlea and auditory nerve and begin to add more intelligence and understanding to the sound as it is passed onto the hearing nerve.

Hearing loss in this section, called sensorineural hearing loss, often results from missing or damaged hair cells in the cochlea and is usually permanent. Mild sensorineural hearing loss can be helped with hearing aids or middle ear implants, but severe losses are typically best solved with cochlear implants. Unfortunately, near total hearing loss resulting from a damaged or missing auditory nerve cannot be solved with cochlear devices because that nerve is responsible for conducting key electrical signals to the brain for understanding and processing.

Cochlear implants have, however, proven to be quite successful in assisting with a variety of sensorineural hearing problems. If the inner ear or nerve pathways aren’t functioning well, causing information transfer issues, a cochlear implant can bypass the defunct hearing section and stimulate the auditory nerve directly with an implanted electrode assembly that acts as a prosthetic substitute. Cochlear systems have an external sound processor that sends digital signals through the skin to the implant, which then sends the signal down to the implanted electrode array in the inner ear. These electrodes stimulate the cochlea’s hearing nerve fibers and forward the sound signals to the brain.

Recent Developments

Both conductive and sensorineural hearing devices undergo continual refinements and design updates. New systems include cochlear designs with implanted stimulators and, for people with more serious hearing impairments, new conductive hearing-assist devices that look like headbands and provide audio entertainment assistance for sporting events or watching TV. New materials and ever-smaller electronics are key to these developments. Companies including Omnetics Connector Corporation, PA&E, and Cristek have brought new products to market that allow medical device manufacturers to focus on comfort and flexibility, making it easier to develop devices that adapt to the active daily lives of those who use them.

Omnetics Nano-Connector

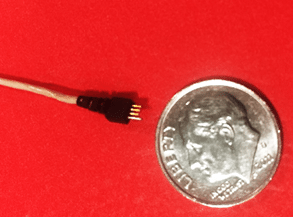

Omnetics has placed particular focus on materials advancements. Years of materials study and process design have helped the company produce extremely thin-wall overmolded insulation and connector jacketing, which reduces overall size and weight while maintaining durability and high-performance. Using special processing techniques, the company has also created miniature cabling and connectors that help medical device designers further advance technology and develop superior new cochlear-type hearing devices.

The cables used in these systems are often the smallest size available on the market, and must also be lightweight, ruggedly constructed for long-life performance, and enable quick, simple connections. Omnetics uses extremely precise, ultra-thin overmolding systems with 100% coverage to keep the cable connectors as small as needed for these and other high-precision applications. Material choices include Santoprene, Evoprene, and other special polyurethanes that are ideal for medical-grade products, and each unit includes one cable that connects the processor to the antennae.

The typical cochlear implant includes six connectors. There is one on each end of the processor-to-antennae cable along with the two board-mounted mates. There is also a board-to-board connection between the battery pack and processor. These connectors are typically nanominiature plastic connectors, and manufacturers often specify custom housings. In addition, they must be rugged enough to withstand repeated mating and unmating cycles and to endure the realities of users’ active lifestyles. Since children are the recipients of many cochlear implants, this precision equipment also needs to be tough enough to withstand a little mishandling.

The benefits these devices bring to the lives of the people who wear them are immeasurable. As demand grows, manufacturers will continue to innovate, looking for new ways to improve what is already an amazing design.

Interested in a specific market? Click a market below for current articles and news.

Automotive, Consumer, Industrial, Medical, Mil/Aero, Datacom/Telecom, and Transportation