The Impact of Positive Train Control

The Impact of Positive Train Control

The Impact of Positive Train Control

Positive Train Control (PTC) systems are integrated command, control, communications, and information systems for controlling train movements with safety, security, precision, and efficiency.

PTC systems, as defined for North American Class I freight railroads, are expected to improve railroad safety by significantly reducing the probability of collisions between trains, casualties to roadway workers, and damage to equipment, as well as “over speed” accidents.

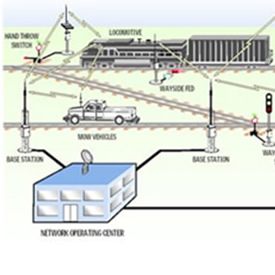

The basic building blocks of PTC architecture are depicted in the diagram at left.

Significant progress is being made toward implementing PTC as US railroads collaborate with federal regulators and suppliers in order to meet a 2015 deadline set by the US Rail Safety Improvement Act of 2008.

Rail industry insiders are recommending that the 2015 deadline for PTC implementation be extended by at least three years, to December 31, 2018, with flexibility given to the US Secretary of the Department of Transportation to consider additional extensions, should they be deemed necessary. This stance is being attributed to both technological and non-technological challenges that have arisen throughout the implementation process.

PTC development and implementation include myriad required tasks:

A complete physical survey and highly precise geo-mapping of the 60,000 miles of railroad right-of-way on which PTC technology will be installed, including geo-mapping of nearly 474,000 field assets (mileposts, curves, grade crossings, switches, and signals)

A complete physical survey and highly precise geo-mapping of the 60,000 miles of railroad right-of-way on which PTC technology will be installed, including geo-mapping of nearly 474,000 field assets (mileposts, curves, grade crossings, switches, and signals)- Installation of PTC technology on approximately 22,000 locomotives

- Installation of approximately 36,000 wayside interface units (WIU), which provide the mechanism for transmitting information to locomotives and the train dispatching office from signal and switch locations

Installation of PTC on nearly 4,800 switches in non-signaled territory and completion of more than 12,300 signal replacement projects at locations where the existing signal equipment cannot accommodate PTC

Installation of PTC on nearly 4,800 switches in non-signaled territory and completion of more than 12,300 signal replacement projects at locations where the existing signal equipment cannot accommodate PTC- Development, production, and deployment of a new radio system specifically designed for the massive data transmission requirements of PTC at 4,200 base stations; 33,700 trackside locations; and on approximately 22,000 locomotives

- Development of back office systems and upgrades to dispatching software to incorporate the data and precision required for PTC

- Installation of more than 20,000 new antenna structures nationwide to transmit PTC signals

The last six points translate into opportunities for electronic connector applications, fueling significant market growth.

PTC systems are comprised of digital data link communications networks; continuous and accurate positioning systems, such as the Nationwide Differential Global Positioning System (NDGPS); on-board computers with digitized maps; maintenance-of-way equipment; in-cab displays; throttle-brake interfaces on locomotives; wayside interface units at switches; wayside detectors; and control center computers and displays.

PTC systems may also interface with tactical and strategic traffic planners, work order reporting systems, and locomotive health reporting systems.

Currently, the estimated total cost to US freight railroads for PTC development and deployment is nearly $8 billion, with hundreds of millions of additional dollars needed every year to maintain the system. This estimated PTC system spend carries an electronic connector component, which may approach $100 million during the 10 years from 2008 to 2018.

Major PTC equipment suppliers, such as Ansaldo-STS, GE Transportation Systems, WABTEC, Alstom, and ARINC consume RF/coax, printed circuit board, circular, rectangular I/O, and terminal blocks for PTC product applications.

Typical RF/coax connectors for PTC applications include N, BNC, TNC, and SMA styles, used in both male and female configurations. These connectors appear onboard in radio equipment as well as trackside in both data collection and antenna applications.

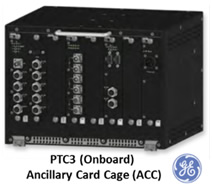

Most of the onboard and back-office applications feature sophisticated card cages with modular circuit cards that perform a host of PTC processes. These card cages utilize backplane connectors for circuit interfaces, as well as circular connectors for system I/O, alongside a full complement of RF/coax devices.

Most of the onboard and back-office applications feature sophisticated card cages with modular circuit cards that perform a host of PTC processes. These card cages utilize backplane connectors for circuit interfaces, as well as circular connectors for system I/O, alongside a full complement of RF/coax devices.

Distributed through all of these onboard and back office systems are multiple subminiature-D connectors, RJ45 jacks, and USB interfaces.

For those familiar with rail topics presented in this publication, what has been presented as the US-based Positive Train Control system looks very similar to the European signaling initiative known as ERTMS in design and function as well as in choice of connector applications.

Simplistically, PTC is based on GPS locational data while ERTMS is based on transponders known as balises bolted to the crossties at fixed locations, establishing fixed location points on known tracks. (See the February 19, 2013 issue of Connector Supplier for more on this.)

The advantage of the ERTMS/balise approach is that locational accuracy on a given track is exact. When a locomotive passes over a balise at milepost X on track X, the system recognizes that the locomotive/train is at a specific location and on a specific track.

Being GPS-based, PTC potentially offers coverage to areas where no current infrastructure exists, known as “dark territory” in the industry. Theoretically, this dark territory can be covered via PTC without major investments in equipment installation.

Many of the equipment platforms and electronic devices supporting both PTC and ERTMS are very similar in design and construction, utilizing similar-performing connectors, generally in off-the-shelf versions.

The pursuit of PTC developments, coupled with ERMTS applications in terms of electronic connectors, offers excellent opportunities, whether or not the 2015 PTC deadline is extended.

- Satellites and 3D Radar Will Drive the Aviation Evolution - October 6, 2014

- Regenerative Braking Systems in Rail Applications - February 13, 2014

- Reinventing Your Wheels: Auto Convergence Technology - November 18, 2013