Military Programs Use Multi-Port and Cluster Connectors for State-of-the-Art RF Performance

Multi-port connectors reduce system cost, speed installation time, and improve reliability. As 5G technologies continue to develop for commercial and military use, these important connectivity solutions will have greatly increased utilization.

The concept of multi-port connectors has evolved from arrays of discrete coaxes to complex assemblies with multiple coaxial contacts, integrated into a single connector housing. Multi-port connectors, with combinations of coax, high-speed digital, optics, signal, and other lines, are growing in use due to benefits offered by reduced system cost and assembly labor, plus increased reliability, small size, and low weight.

By definition, multi-port connectors are usually cable-to-equipment connectors. This designation separates them from the many multi-contact board-to-board and fly-over type connectors available on the market. They originally started as mil/aero concepts since these applications involved expensive assemblies and could achieve significant benefits from the advantages these connectors offer. Multi-coax assemblies have also become favorites for commercial applications involving instrumentation, test, and telecom, including 5G. To successfully specify multi-port connectors, designers need to understand and combine a variety of otherwise independent interconnect components into one common assembly.

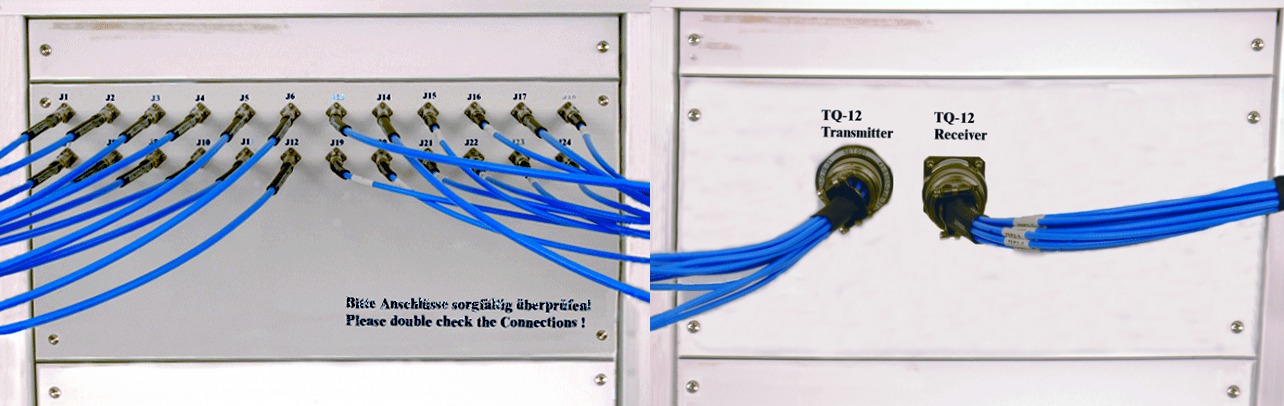

Visualize the time and effort involved in mating the 24 coax connectors shown below in the image on the left. You can get the same results with a quick-turn mating of just one or two multi-cavity connectors with positive locking indicators, as shown on the right. And don’t forget the time and cost for the panel holes and mounting hardware. That’s the basic concept behind multi-port connectors, but there is a lot more involved.

These images from Spectrum Elektrotechnik GmbH illustrate the simplicity that multi-port connectors offer over the use of multiple separate coax connectors.

The use of industry-standard mil-spec connectors as the base design for multi-port connectors has resulted in the adoption of MIL-DTL-38999 connectors for commercial assemblies. Versions that use standard and custom MIL-DTL-24308s are also available. Multi-housing solutions and those with ganged inserts include stacked Combo-D and ARINC assemblies.

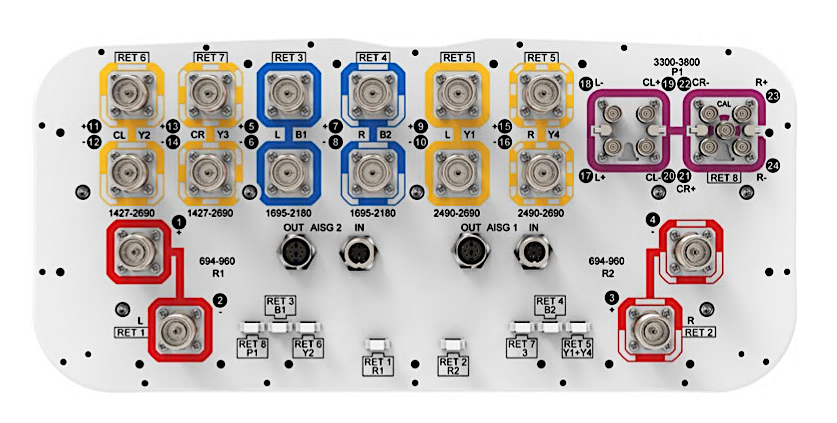

These MIL-DTL-38999 Series III multi-port connectors from Amphenol SV Microwave use high-frequency coaxes instead of standard contacts.

The reliability benefits of mating one pair of multi-contact connectors versus mating dozens of single-line pairs can be readily quantified with mean time between failures (MTBF) calculations per MIL-HDBK-217. Labor cost is reduced, as the incoming cables can be produced separately and involve quick installation and almost foolproof mating. Proper installation and retention of individual coaxes within the assembly can be quickly checked on a line-by-line basis prior to mating. Within the same relative package size, microwave performance can vary due to supplier-specific coax designs, plus variations in PCB layout and materials if the mating receptacle is board mounted. In addition, the cable used, the other cable-end connectors, and the quality of the terminations for the mating plug assembly introduce further variation.

The MIL-DTL-38999 Series III assembly by Southwest Microwave (SMI) features a combination of size 16 and 12 coaxes and non-coax signal contacts. The company also offers larger size 8 and smaller size 20 coaxes, plus different size 20 coaxes for standard MIL-PRF-24308 D-Sub connectors that were originally designed for MS crimp contacts. They are also well suited for use in custom Micro-D connectors and deliver performance from DC to 110GHz, depending upon the cable used. To assure performance, the size 20 coaxes are offered only with terminated cable.

Ruggedness and environmental sealing are often considered assured since the outer connectors themselves have been qualified to applicable specifications. However, this writer knows of only one connector supplier that has provided data to confirm that their coaxes meet the same vibration and shock levels of the mil-spec connectors in which they’re being used. Coax assemblies have many parts and any component movement can affect microwave performance. Another problem is that the coax interfaces are supplier-specific; while they may be based on defined SMPM or BMA/BMMA interfaces, or even something proprietary, their dimensional placement — both within the cavity and with respect to the RF reference plane — and their mating compression distances and forces are not standardized. To achieve vendor-stated results, both mating sides must be provided by the same supplier. In spite of the purchasing flexibility limitations of this sole-source scenario, the benefits gained make this a growing product trend.

A good example of evolution in RF/microwave performance is illustrated by D-subminiature connectors. D-subs have been around since the 1950s, when they were first offered by ITT Cannon. Unlike multi-ports for high-gigahertz performance, the coaxes used in combination D-sub (Combo-D) connectors are intended for lower-frequency RF and produced with generous tolerances to permit supplier intermateability; although, users should still test to confirm performance. Combo-Ds are available with coaxes and power contacts, and combinations including standard size 20 signal contacts. Combo-D coaxes are size-equivalent to large size 8 contacts and are available in both 50Ω and 75Ω variants, typically for up to 1GHz. In addition, combo-D contact arrangements in shell size “B,” which is used for the popular DB-25 pinout in RS-232 serial ports, can have up to five coaxes.

Stacked Combo-D connectors from Positronic (left), Quadrax D-Sub connectors from TE Connectivity (middle) and custom DC 40Ghz connectors in D-Sub housings from Phoenix Company of Chicago (right).

5G Commercial and Military Cluster Connectors

In the commercial world, where mil-spec multi-ports are deemed too expensive, the same requirements to minimize space and weight, reduce assembly time, and improve systemic reliability have resulted in multi-coax assemblies called cluster connectors. Non-coax cluster connectors have a long history of use in cars for dashboard instrumentation and other grouped assemblies, but incorporating RF/microwave coaxes is relatively new. While traditional U.S. military specifications promote standardization, newer coax connector standards have been issued by international organizations such as the International Electrotechnical Commission (IEC). These tend to be more application-specific, defining issues such as low PIM levels, environmental sealing, and low-loss transmission, plus EU RoHS, REACH, and other requirements.

5G was first launched as a commercial network, but the most important 5G applications may be for military domain. 5G has inherent anti-jamming qualities and will provide military operations with improved intelligence, surveillance, and reconnaissance (ISR) systems and processing to enable new methods of command and control (C2) and streamline battlefield logistics systems. Military adoption of 5G is already underway for 12 designated bases, supported by a DoD budget request for $1.5 billion for 5G in FY2021 up from a projected expenditure of $436 million in FY2020. Due to program economics and speed of implementation, equipment designed for commercial 5G, including its RF connectors, will become basics for tomorrow’s military installations, mobile-van command centers, plus fixed and portable equipment.

A key consideration for new 5G connectors concerns the cluster connector assembly being considered as a worldwide standard by the Next Generation Mobile Networks Alliance (NGMN), which consists of leading global mobile network operators and providers working to establish standards for network infrastructure, service platforms, and related devices. (Contributor partners include several major connectivity suppliers, such as Radiall, Rosenberger, Amphenol Antenna Solutions, and HUBER+SUHNER.) Projected quantities are very significant, as applications include the tens of thousands of small-cell sites that will be installed at an every-other-building spacing in densely populated areas, often above streetlights and even hidden inside the large golden arches at McDonald’s. The connectors would be the primary interconnection for mobile radios using time-division duplexing (TDD) and for uplink and downlink transmission employing beamforming frequency-division duplexing (FDD). The most popular format is eight transmitters and eight receivers (8T8R), as those with higher quantities of ports will employ fiber optics to minimize space, with similar installations expected for telecom, industrial, and military applications.

The NGMN cluster concept, called M-LOC, was proposed by CommScope. It incorporates either eight or nine NEX10 connectors, as defined by the NEX10 Consortium, which ensures interchangeability between products by multiple suppliers. (Radiall, Rosenberger, Amphenol, HUBER+SUHNER, and IMS Connectors Systems are among the suppliers involved with this initiative.) Confirmed intermateability and interchangeability is a major difference between these commercial cluster connectors versus other types of high-frequency multi-port connectors. Even in the unlikely case that multi-port connectors use the same mil-spec housings, each supplier currently has its own proprietary version of the coax assemblies involved, and intermateability and RF performance are not assured unless all mating coaxes are from the same vendor.

The figures below are from CommScope. The first shows an 8T8R site antenna base with 25 connectors, typical of today’s equipment. RF path design requires each radio port to be mated to a specific port on an individual antenna. Connector mating torque is always important but is especially critical here, as either high or low forces would increase PIM level and reduce data capacity.

This CommScope image depicts a grouping of nine NEX10 connectors for 8T8R plus a calibration line (the center pin in the top right connector), which has two latches and a bell-shaped keyed area to control alignment with five NEX10 receptacles. Each grouping of four or five is mated simultaneously with a M-LOC cluster connector assembly.

An antenna array can have as many as 60 connectors and towers are usually multi-array. The cluster solution integrates multiple ports into a single interface that eliminates interconnection errors, maintains PIM performance, and saves time. To illustrate connection time, CommScope’s video shows complete mating by M-LOC of five ganged NEX10 coaxes in just three seconds versus individual lines at one minute and 32 seconds.

CommScope’s M-LOC cable assembly with five NEX10 male plug connectors are pictured on the left. The center contact is for calibration while the outer four are antenna connections for 5G applications to 6GHz. Aside view of an antenna with two M-LOC cabled assemblies mated to the base is pictured on the right.

Whether it’s called a multi-port connector or a cluster connector, new types of multi-coax assemblies are being used to advance RF/microwave interconnect technology worldwide and will have wide utility in critical military and commercial applications, including 5G infrastructure as it comes into full use.

Like this article? Check out our other Connection Basics and cable assemblies, circular connectors articles, our Datacom/Telecom and Military/Aerospace Market Pages, and our 2020 and 2019 Article Archives.

- New Circular Connectors Add to Multi-Billion Dollar Market - January 9, 2024

- Counterfeit Components Ground Airlines - December 12, 2023

- Cables, Connectors, Waveguides, and Hybrid Products for up to THz at IMS 2023 - July 11, 2023