Non-Magnetic RF Connectors are Critical Enablers for Advanced MRI Technologies

Emerging MRI technologies rely on a new generation of non-magnetic RF connectors that offer advanced performance in smaller and lighter configurations.

Magnetic resonance imaging (MRI) techniques provide several benefits over other medical imaging techniques and are increasingly employed in application areas outside of their well-established neurological roots. Encouraging new medical developments range from new and improved MRI technologies, including magnetic resonance angiography (MRA) equipment, cardiac MRI (CMRI) equipment, and higher-resolution MRI machines with more powerful magnetic fields, to new medical devices designed for MRI compatibility.[1] These trends are also encouraging innovation at the component level and increasing the demand for non-magnetic radio frequency (RF) connectors, which are critical to the development of MRI technologies.

MRI Connectivity Challenges

MRI machines rely on extensive arrays of non-magnetic RF connectors, contacts, coils, and cables to send and receive the pulsed RF signals used to image patients, as the presence of any ferromagnetic material in these components could interfere with the magnetic field response and reduce imaging accuracy. Many leading connector suppliers have successfully surmounted the challenges of achieving optimized interconnect performance with exclusively non-magnetic materials while also satisfying stringent medical design demands, but the latest advances in MRI technology are creating new RF connectivity challenges.

For instance, many emerging MRI advancements are focused on significantly increasing the strength of the machines’ magnetic field from the current 1.5 to 3 Tesla to 7 or even 10+ Tesla to further improve the resolution and signal-to-noise ratio of MRI scanners.[2, 3, 4, 5] These enhancements hinge on the quality of the non-magnetic RF connectivity components used to carry RF pulses and sense the weak signals returned by magnetically realigning protons and thus require both more and higher-density, higher-performance RF interconnect solutions than previous MRI technologies. In addition, new MRI typologies that employ arrays of magnetic field probes instead of conventional surface coils are the subject of several ongoing research and development projects.[6] These new magnetic-probe MRI machines could lead to much higher-resolution MRI capabilities but would also require more non-magnetic RF interconnect and signal processing circuitry.

Cinch Connectivity Solutions’ Johnson® Type-N Non-Magnetic Connectors have brass bodies with tri-alloy or gold plating to prevent intermodulation issues, a rugged interface plated with 50μin of gold for excellent high-frequency performance and durability, sealing gaskets for environmental protection, and hex nuts for specific mating torques.

In order for higher-Tesla MRI machines to effectively leverage the higher spatial resolution capabilities that stronger magnetic fields enable, the RF receiver and RF path must prevent as much loss and distortion as possible, which requires thoughtful materials selections, effective shielding mechanisms, and strategic component and systems designs. Both higher-Tesla MRI and magnetic-probe MRI machines also require higher RF interconnect densities, which will increase the demand for non-magnetic RF connectors in high-density board-launch, end-launch, ganged board-to-board, and cable assembly configurations. In addition, like most modern electronics systems, MRI machines are subject to increasingly demanding size, weight, and power (SWaP) requirements. But, given that the vast majority of RF interconnect suppliers offer a limited selection of non-magnetic RF solutions compared to their standard RF component offerings, MRI manufacturers often have limited options for reducing the size and complexity of their systems.

Non-Magnetic RF Connectors for Medical Applications

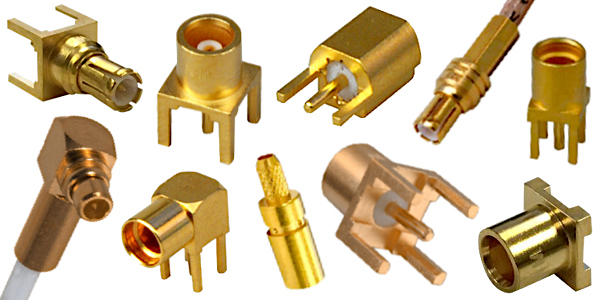

A wide range of non-magnetic RF connector types are suited for use in MRI applications, including Type-N, SMA, BNC, SMB, SMC, MCX, MMCX, SMP, SMPM, and 2.92mm coax connectors. The type of connector selected for a design depends on its frequency, signal power, connection point geometry, insertion loss, and installation characteristics. There also tends to be a tradeoff related to the size, frequency, power handling, and insertion loss of non-magnetic RF connectors. Typically, smaller RF connectors are able to channel higher frequencies, but at the cost of lower maximum power handling capabilities and increased insertion loss. However, several RF interconnect suppliers have developed specialized materials and design techniques that mitigate the insertion loss of smaller RF interconnects and enable the high-performance miniature and microminiature RF connections that advanced MRI equipment demands.

Cinch Connectivity Solutions’s extensive line of microminiature Johnson MCX and MMCX Non-Magnetic Coax Connectors have a positive, snap-on coupling design that supports high-density connectivity and high mating cycles.

Each of the various types of non-magnetic RF connectors also comes in a range of configurations, including end-launch, right-angle, straight, bulkhead, and surface-mount receptacles. The connector configuration chosen for a particular connection depends on its geometric requirements and how the cable or board connector is designed to be installed. For instance, board-mount RF connectors can help mitigate the potential footprint increase that additional RF sensors would contribute to MRI machines with higher densities of RF probes or magnetic coils. Although MRI machines are often large pieces of equipment, the physical space available for enabling electronics tends to be rather limited, especially in the patient housing area, as the superconducting magnet and MRI probes to be as close to the patient as possible. So, smaller and intelligently configured board-mount non-magnetic RF connectors will be critical enablers for the continued development of more compact and more capable MRI machines.

Traditional RF connectors have threaded bodies that require precise torque values, and hence torque wrenches, to properly install. Snap-on, push-in, and blind-mating style RF connectors are designed to establish secure mechanical and electrical connections upon being simply pressed together with adequate force. These are widely available and include SMP and SMPM types. Blind-mating connectors are designed to prevent mating misalignment and, depending on the connector design, may also include sophisticated self-aligning features, both of which can be crucial during assembly, installation, and maintenance processes in space-constrained designs.

Expanding Application Areas for Non-Magnetic RF Connectors

In addition to developing higher-resolution MRI machines with more powerful magnetic fields and arrays of magnetic field probes instead of conventional surface coils, there is growing interest in extending the use of MRI technologies into more application areas, including magnetic-resonance angiography (MRA) and cardiac MRI (CMRI) equipment. The medical industry is also experiencing increased demand for implantable technologies that are both compatible with current and future MRI equipment and capable of wireless control. Legacy implantable medical technologies, including stents and pacemakers, were made with ferromagnetic materials that preclude patients from leveraging high-resolution MRI imaging technologies for their care and, instead, limit them to lower resolution computed tomography (CT) or rarer and more expensive single-photon emission computed tomography (SPECT) scans. They also required wired connectivity for device access, control, and monitoring, which complicated the process, inconvenienced patients, and increased the cost of care.

Like the higher-Tesla and probe-array MRI machines currently in development, new MRI-compatible implantable medical devices capable of wireless control will also require miniaturized, high-performance, non-magnetic RF connectors proven to satisfy the stringent electrical, mechanical, and environmental demands of the medical industry. As medical technologies continue to advance, so too do the requirements for the non-magnetic RF connectors essential for carrying the signals used to construct MRI images or provide fail-safe wireless connectivity. So, it’s critically important to leverage the diverse range of high-quality, tested and proven non-magnetic RF connectors available to ensure optimal performance and mitigate risk.

Using a trusted supplier with a wide range of non-magnetic RF connector solutions, extensive experience in the microwave and RF and medical industries, qualified manufacturing facilities, and proven testing and verification capabilities can also be beneficial not only during the design and production processes, but throughout the lifetimes of MRI machines and other medical equipment [7]. High-quality RF connectors can yield better-performing MRI machines with higher accuracy and reliability, less downtime, and lower maintenance costs compared to machines built using lower-quality connectors that are more likely to have magnetic impurities, reliability issues, and standards compliance challenges.

Cinch Connectivity Solutions’ extensive line of Johnson Non-Magnetic Coaxial Connectors is made using high-purity copper alloys to ensure the absence of ferrous materials and provides high-frequency performance from DC–65GHz with superior signal integrity in MRI and MRA applications. Solutions include MCX, MMCX, SMA, SMB, and Type-N connectors in straight and right-angled cabled, PCB-mount, and end-launch configurations with gold-plated contacts, crimp or solder terminations, and a wide range of cable types.

About the Author

Ketan Thakkar is the product manager for Cinch Connectivity Solutions’ Johnson RF & Microwave product line. He has a bachelor’s degree in electrical engineering from University of Illinois at Urbana-Champaign, a decade of hardware design engineering experience in the communications and consumer electronics industries, a decade of sales and field application engineering experience in the electronic semiconductor industry, and a decade of product management experience in the electronic interconnect industry.

Visit Cinch Connectivity Solutions online.

Like this article? Check out our other Connector Basics, How-to-Specify, and RF and Coax articles, our Medical Market Page, and our 2020 and 2019 Article Archives.

Resources and References

- Thakkar, Ketan, “Why MRI Machines and MRI-Compatible Medical Devices are Dependent on Non-Magnetic RF Connectors,” Cinch Connectivity Solutions, June 2019. Available at https://belfuse.com/resources/whitepaper/cinchconnectivityolutions/johnson/wp-CCS-JOHN-mri-dependent-on-non-magnetic-rf-connectors.pdf.

- Zagoudis, Jeff, “Will Cardiac MRI Expand?” Imaging Technology News, May 3, 2018. Available at https://www.itnonline.com/article/will-cardiac-mri-expand.

- “Magnetic Resonance Imaging (MRI) Market – Growth, Trends, and Forecast (2019 – 2024)” Mordor Intelligence, June 2019. Available at https://www.mordorintelligence.com/industry-reports/global-mri-market-industry.

- Nowogrodzki, Anna. “The World’s Strongest MRI Machines are Pushing Human Imaging to new Limits,” Nature, October 31, 2018. Available at https://www.nature.com/articles/d41586-018-07182-7 [Verified November 14, 2019].

- Bera, Tushar Kanti, “Noninvasive Electromagnetic Methods for Brain Monitoring: A Technical Review,” Intelligent Systems Reference Library, v74, p51–95, November 2015. Available at https://www.researchgate.net/publication/281687317_Noninvasive_Electromagnetic_Methods_for_Brain_Monitoring_A_Technical_Review.

- Stucht D, Danishad KA, Schulze P, Godenschweger F, Zaitsev M, Speck O, “Highest Resolution In Vivo Human Brain MRI Using Prospective Motion Correction,” PLoS One. v10(7), July 30, 2015. Available at https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4520483/.

- Miller, Jen, “Updating High-Resolution MRI,” Michigan Tech News, October 31, 2018. Available at https://www.mtu.edu/news/stories/2018/october/updating-highresolution-mri.html

- “Non-Magnetic Connectors Product Catalog,” Cinch Connectivity Solutions, June 2017. Available at https://www.belfuse.com/resources/catalogs/cinchconnectivitysolutions/johnson/ca-ccs-john-johnso-non-magnetic-catalog.pdf.