Quality Connectors Boost Rail Industry Dependability

As modern train systems integrate passenger comforts, supply chain visibility, and smart infrastructure connectivity, quality components become more critical.

Increasing demand for connected technologies in rail networks extends from new trains and signaling systems to updates for existing equipment, including high-speed connectivity for rail operators and passengers, real-time tracking and visibility for cargo, and integration of intelligent transportation systems (ITS).

Demand for rail services is increasing; demand for freight and passenger movement is expected to double between 2019 and 2050. The electronics that serve the rail industry will grow in tandem to meet this demand and bring connectivity to every aspect of rail service.

Connector Quality Comes in Focus

John Moore, senior business development manager for rail transportation infrastructure at Phoenix Contact, says that the rail industry is set to benefit from shifts toward environmentally sustainable transport, which include using rail transportation as opposed to other less sustainable modes of transportation. He predicts growth in transportation infrastructure investment from both government and private sources. He also sees a greater understanding across the industry that rail applications require high-quality components that can withstand the unique rigors of this mode.

“The rail industry knows that just the name ‘connector’ puts them on the high-priority, high-quality, best-in-class list when it comes to budgeting and sourcing,” said Moore. “Think about it — a connector connects two or more components. This is a very important role for small items that sometimes appear inconsequential or unimportant. Think now of the word ‘disconnect,’ which has the opposite meaning. Disconnecting a connector is a good thing at the right time and for the right reasons, but at the wrong time and for the wrong reasons — as in a failure of the connector itself — this presents a serious problem. We don’t like disconnects in many aspects of our lives, for example, in our communication with family or working colleagues or in our home electrical systems. So why would we consider anything less than the best to ensure robust connections in all areas of the rail industry? Onboard, at the wayside, in the back office, are all locations that need the assurance of excellent connections that excellent connectors provide.”

Phoenix Contact’s M12 connectors with QUICKON conductor connections are widely used for the field installation of analog and digital devices employed onboard passenger trains, buses, and other mobile equipment.

Tight budgets are one factor that can interfere with the proper selection of connectors. Connectors are often viewed as a low-priced commodity, so some operators may not have a heightened concern for their quality. But connector quality matters a great deal, especially in critical transportation systems. Without the reliability high-quality components deliver, a connector could become a single point of failure.

“Small items that don’t appear to have much importance are usually the ones that can cause us the most trouble,” says Moore. “There is a saying, ‘The bitterness of poor quality remains long after the sweetness of low price is forgotten.’ Tight budgets are many times the driver of purchasing decisions, and these decisions are not always aligned with business goals. For a freight railroad, these goals can mean maximizing revenue time. For transit, these goals can mean shortened headways and on-time arrivals and departures. And for intercity passenger rail, the goals are similar: keep revenue-generating trains moving, on time and without incident. The need to meet business requirements and goals sometimes conflicts with meeting business budgets. But buying cheaper may mean higher costs, such as lost revenue, lost reputation, and lost good will.”

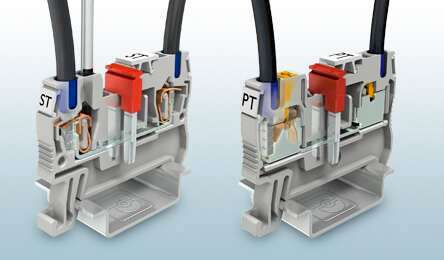

Rail components are subjected to strong vibrations, so maximum contact reliability is essential. Phoenix Contact’s spring-cage connection terminal blocks provide a constant connection; the spring always exerts the same force on the conductor, regardless of influence or vibration.

Ruggedized for the Rail Industry

In railroad applications, connectors must meet international standards, beginning with EN 50155, which covers electronic equipment used on rolling stock (rail cars) for railway applications. This standard defines performance parameters for components that are exposed to the rugged environmental conditions that are common to rail applications, including temperature, humidity, shock, vibration, and other parameters. Designers must confirm that components that deliver the desired performance can also endure these conditions and meet all additional country-specific standards.

“Connector manufacturers can usually provide that information, as product development is usually application driven,” says Moore. Rail applications have always emphasized ruggedization, but as rail networks increasingly merge with smart city infrastructure and multimodal connected technologies, communications solutions must also deliver the high level of signal integrity and performance expected of stationary systems.

“The connectivity supply in train coach is growing exponentially. Wi-Fi connections, information systems, and security cameras are the main important application in the new evolution of rolling stock. As more and more passengers access Wi-Fi on trains, operators require connectors that offer services that are up to the task,” said Paolo Colombo, VanSystem marketing manager, Radiall.

Radiall provides high-reliability communication solutions for railway applications, including RF, fiber optic, electric, power, and high-speed data connectivity products. These products are designed to serve in railway station and signal communication systems, onboard communication systems, and trackside telecommunication equipment.

Radiall VanSystem’s GM Modular Connectors can support Ethernet and data transmission, coaxial connections, fiber optics, power cables, and up to 14 signal wires, offering extreme versatility for rail applications. In addition, each module is independent, which eliminates interference and allows users to create many combinations of connections while still optimizing space.

The company’s VanSystem line also offers circular, power, and modular connectors for rolling stock, like the GVJ Oversize Connectors, which are ideal for use in harsh-environment undercar applications including brake control systems, battery chargers, auxiliary converters, and inverters. These threaded and bayonet-style connectors were originally designed for military and aerospace applications and meet the MIL-DTL-5015 standard and feature bigger shell thicknesses and protected coupling points. The qualities that make them suitable for military and aerospace equipment also serve the demanding rail industry, as the electronics in rolling stock face hazards including shock, debris, vibration, and frequent mating and unmating.

Radiall VanSystem’s GVJ Oversize Connectors

“Connectors are some of the most critical pieces of equipment in railway installations. They are installed in track, brake, controls, signaling, and power transmission systems, all of which must be carefully engineered to guarantee the safety of passengers,” said Colombo.

As rail operators update existing stock and add new equipment with communications systems that can facilitate ITS, the connectors specified to make these connectors are critical to ensuring the dependability and comfort of modern rail systems.

For more information on connectors for Rail Applications:

Rail Connectivity Trends

Interconnect Solutions Drive the Evolution of Rail Mobility

Maximize UL Voltage Ratings in Power and Control Systems for Mobile Equipment

Ethernet Connectors for Transportation Applications Roundup

Rail Connectors Product Roundup

Like this article? Check out our other Connector Basics, ruggedized connector, and rail articles, our Transportation Market Page, and our 2020 and 2019 Article Archives.

- State of the Industry: 2022-2023 Connector Sales - April 16, 2024

- Amphenol is On a Roll - April 2, 2024

- Nicomatic Proves That Two Heads are Better Than One - March 26, 2024