Will Copper Conductors Hit a Wall?

Optimistic technologists have been predicting fiber optics would replace many copper links since the late 1990s, but designers were able to find ways to extend the bandwidth and reach of copper. Now we may be reaching the point where fiber may finally become the most practical solution in an increasing number of applications.

Electrical interconnects that utilize copper conductors have been the mainstay of the industry since its inception, and for good reason. Copper has excellent electrical conductivity, malleability, flexibility, good thermal conductivity, and is widely available at a reasonable cost. Copper can easily be drawn into continuous wire and insulated with materials ranging from a thin varnish to PTFE (Teflon), thermoplastic, and other extruded materials. Copper alloys that exhibit spring characteristics have enabled the design of connector contacts that maintain adequate normal forces over a long service life. Contacts can be plated with a variety of metals, most commonly tin and gold, for protection from corrosion and reduced contact resistance. Depending on the diameter of the conductor, both power and low-level signals can be efficiently conducted.

Electrical interconnects that utilize copper conductors have been the mainstay of the industry since its inception, and for good reason. Copper has excellent electrical conductivity, malleability, flexibility, good thermal conductivity, and is widely available at a reasonable cost. Copper can easily be drawn into continuous wire and insulated with materials ranging from a thin varnish to PTFE (Teflon), thermoplastic, and other extruded materials. Copper alloys that exhibit spring characteristics have enabled the design of connector contacts that maintain adequate normal forces over a long service life. Contacts can be plated with a variety of metals, most commonly tin and gold, for protection from corrosion and reduced contact resistance. Depending on the diameter of the conductor, both power and low-level signals can be efficiently conducted.

Over the years, reliable termination techniques, including solder, crimp, insulation displacement, compliant pin, and compression, have been perfected to the point that consistent connections can be mass produced. Highly automated wave and reflow soldering equipment can make thousands of permanent connections on a printed circuit board within seconds. Copper connectors can be terminated in the field using readily available tools. The global connector industry has developed literally thousands of copper connector configurations, including miniature, coaxial, ruggedized, power, soft shell, backplane, stacking, hermetic, PCB, cable, and mass terminated flat flex cable. These are all good reasons to expect copper to continue to reign supreme in the electronic interconnect world. However, the laws of physics may begin to interfere with that expectation in select applications.

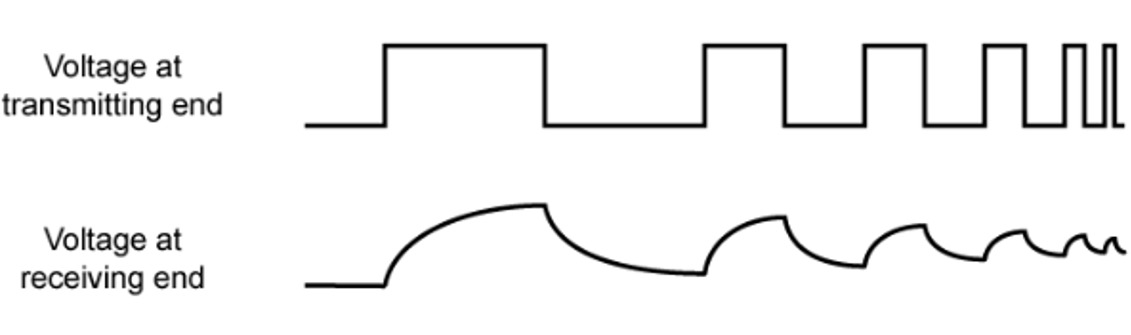

As signal speeds continue to increase, copper links begin to exhibit several detrimental effects. In addition to attenuation due to simple resistance in the circuit, factors such as near- and far-end crosstalk, reflections, skew, and intersymbol interference begin to degrade the signal. A clean square wave generated at the transmitter may appear as a low-level undulating wave at the receiver.

The degree of signal distortion increases with the length and speed of the signal. This was not a concern to circuit designers when data rates were in the sub-gigabit range, but the industry passed that gate years ago and now leading-edge requirements are pushing 56+Gb/s non-return to zero (NRZ).

The short- and mid-term solution to this problem has been a combination of improved PCB layout rules, upgraded PCB material, optimized connector designs, advanced signal conditioning, and more recently, the adoption of PAM4 signaling. Active optical cables have been utilized to increase the maximum specified length of copper USB, Ethernet, InfiniBand, and DisplayPort cable assemblies. To a large degree, these tools have enabled system engineers to design state-of-the-art commercial, industrial, military, and consumer devices using traditional copper interconnects.

Optimistic technologists have been predicting fiber optics would replace many copper links since the late 1990s, but designers were able to find ways to extend the bandwidth and reach of copper to satisfy increasing performance demands. We may finally be reaching the point where fiber could become the most practical solution in an increasing number of applications.

Optical signaling offers attractive attributes, including:

1. Increased channel capacity

2. Dramatically increased reach and signal integrity

3. Lower power consumption/less heat generated

4. Reduced latency

5. EMI/RFI/ESD immunity as well as improved security

6. Reduced cable size and weight, which enables increased system packaging and panel density

Broad market adoption of fiber suffered from multiple issues, including a difficult and time-consuming termination process, increased cost of the electro-optic conversion process, susceptibility to contamination at the optical interface, as well as perceived fragility of glass fiber. Many of these concerns have been allayed as advanced fiber optic cable, connectors, and silicon photonic transceivers were introduced. Improved fiber optic cables are more rugged and resistant to damage from a tight bend radius. Pre-polished connector assemblies simplify and improve termination consistency of optical fibers. Many recently introduced connectors feature expanded beam technology that reduces susceptibility to interface contamination. A unique class of hollow-core fiber offers reduced signal latency where speed is the prime objective.

The infrastructure that supports cloud and edge computing is a key segment that may be one of the first to push performance beyond the limits of copper. High-speed metro and long-distance links between hyper data centers have often been implemented in fiber optic cables. Improving the spectral efficiency of existing fiber has become the focus in the effort to increase the data capacity of optical channels. Wave division multiplexing (WDM) has proven to be one of several effective solutions. Rather than utilize a single color of light, multiple data streams can be sent simultaneously over the same fiber using slightly different colors of light. Capacity of a single fiber utilizing additional bands is being implemented using several technologies. The C+ band is slightly wider than the traditional C band. The full utilization of the C+ band can provide up to 125 high-speed channels per fiber. Coherent transmission combines four levels of amplitude and phase modulation with vertical and horizontal polarization of light to maximize the data capacity of a single fiber.

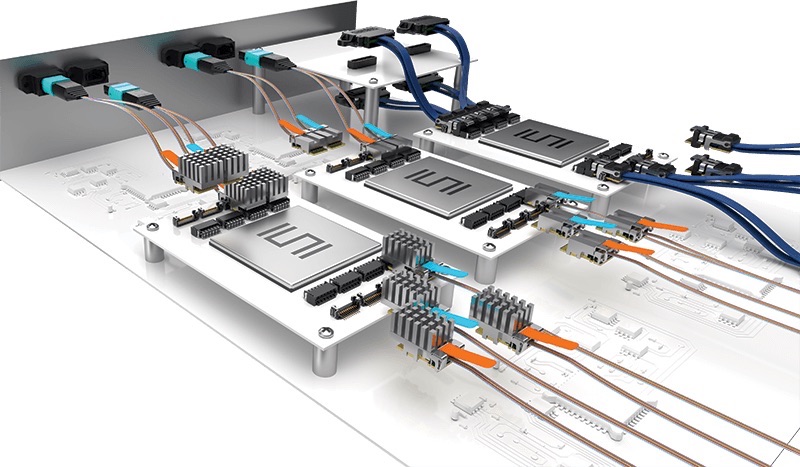

Samtec’s FireFly™ Micro Flyover System™ uses both copper and optical cable to offer improved design flexibility and simplify board design, achieve higher data rates (up to 28Gb/s) over greater distances, and enhance performance.

Advanced fiber optic cable is durable and versatile, making it a solid choice for high-speed applications. (Image courtesy of Corning)

In addition to long-distance channels, fiber optic links are now being utilized in much shorter internal applications. As system speeds increase, signals propagated in even high-performance PCB laminate material generate increased attenuation and distortion. Efforts to integrate an optical plane directly into a multilayer PCB have not proven practical to date. An alternative solution is to convert the electrical signals to optical pulses and convey them over the surface of the PCB via discrete or ribbon fiber. Mid-board optical transceivers can be mounted close to the source of high-speed signals, reducing the loss attributed to copper PCB traces. These optical links can be terminated in high-fiber count connectors that have the potential to greatly increase signal density on the I/O panel.

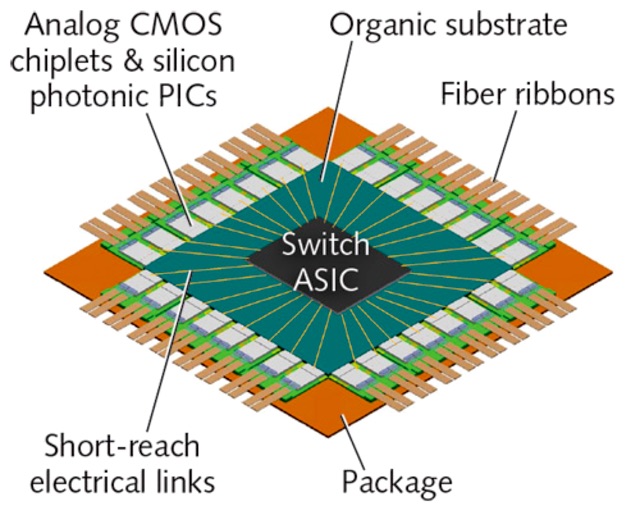

The most current step in this transition is the development of co-packaged optics where optical engines or chiplets are located on the same substrate as an ASIC or switch, reducing the copper signal path to a minimum.

Co-packaged optics reduce the copper signal path, in turn reducing power consumption and latency. (Image courtesy of LaserFocusWorld)

The pace of optical technology and product introduction is accelerating at a time when data rates and signal fidelity are putting pressure on the limits of traditional copper interconnects. Advanced fiber optic links are expanding from traditional long-reach applications to relatively short runs within a data center and even inside the box where high-speed and signal integrity are essential. Recent developments, including coherent optical signaling, greatly increase the efficiency of optical channels while emerging co-packaged optics technology promises a roadmap to even higher data rates and I/O panel density.

Bob Hult is the author of the Bishop & Associates’ High-Speed Copper & Fiber Optic Connectors report, a new 15-chapter, 234-page publication that examines the evolution of leading-edge copper and fiber optic interfaces. The new report reviews how high-speed copper and fiber optic connectors are continuing to evolve to support the ever-increasing demand for higher bandwidth, signal integrity, increased panel density, and reduced power. State-of-the-art copper printed circuit board interfaces continue to exceed perceived performance limitations through a combination of fine tuning of the internal signal path, optimized PCB launch, advanced signal conditioning, and adoption of PAM4 modulation. High-performance shielded differential pair cables can significantly increase the reach of high-speed signals. Advances in fiber optic technology, including advanced fiber, silicon photonic devices, as well as connectors, are providing opportunities for optical interfaces to become the most cost-effective solution in an increasing universe of applications. Visit Bishop & Associates for more information.

Bob Hult is the author of the Bishop & Associates’ High-Speed Copper & Fiber Optic Connectors report, a new 15-chapter, 234-page publication that examines the evolution of leading-edge copper and fiber optic interfaces. The new report reviews how high-speed copper and fiber optic connectors are continuing to evolve to support the ever-increasing demand for higher bandwidth, signal integrity, increased panel density, and reduced power. State-of-the-art copper printed circuit board interfaces continue to exceed perceived performance limitations through a combination of fine tuning of the internal signal path, optimized PCB launch, advanced signal conditioning, and adoption of PAM4 modulation. High-performance shielded differential pair cables can significantly increase the reach of high-speed signals. Advances in fiber optic technology, including advanced fiber, silicon photonic devices, as well as connectors, are providing opportunities for optical interfaces to become the most cost-effective solution in an increasing universe of applications. Visit Bishop & Associates for more information.

Like this article? Check out our other High-Speed, Fiber Optics, and Market Update articles, our Datacom/Telecom and Wire /Cable Assemblies Market Pages, and our 2021 and 2020 Article Archives.

- Optics Outpace Copper at OFC 2024 - April 16, 2024

- Digital Lighting Enhances your Theatrical Experience - March 5, 2024

- DesignCon 2024 in Review - February 13, 2024